B21, China Town Mall, Midrand

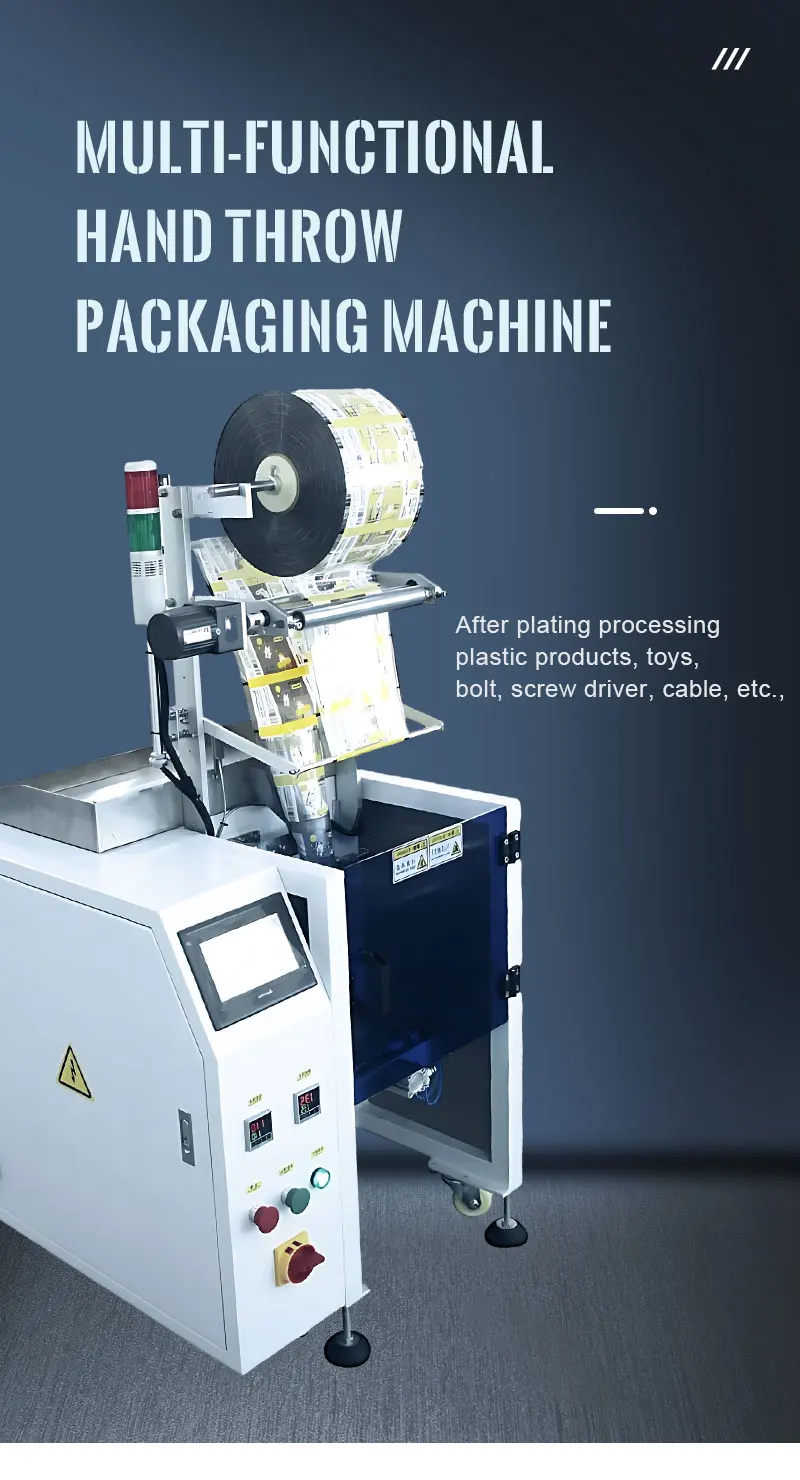

Automatic packaging machine With high speed multipurpose

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1600230941618

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum packing speed of the Automatic Packaging Machine?

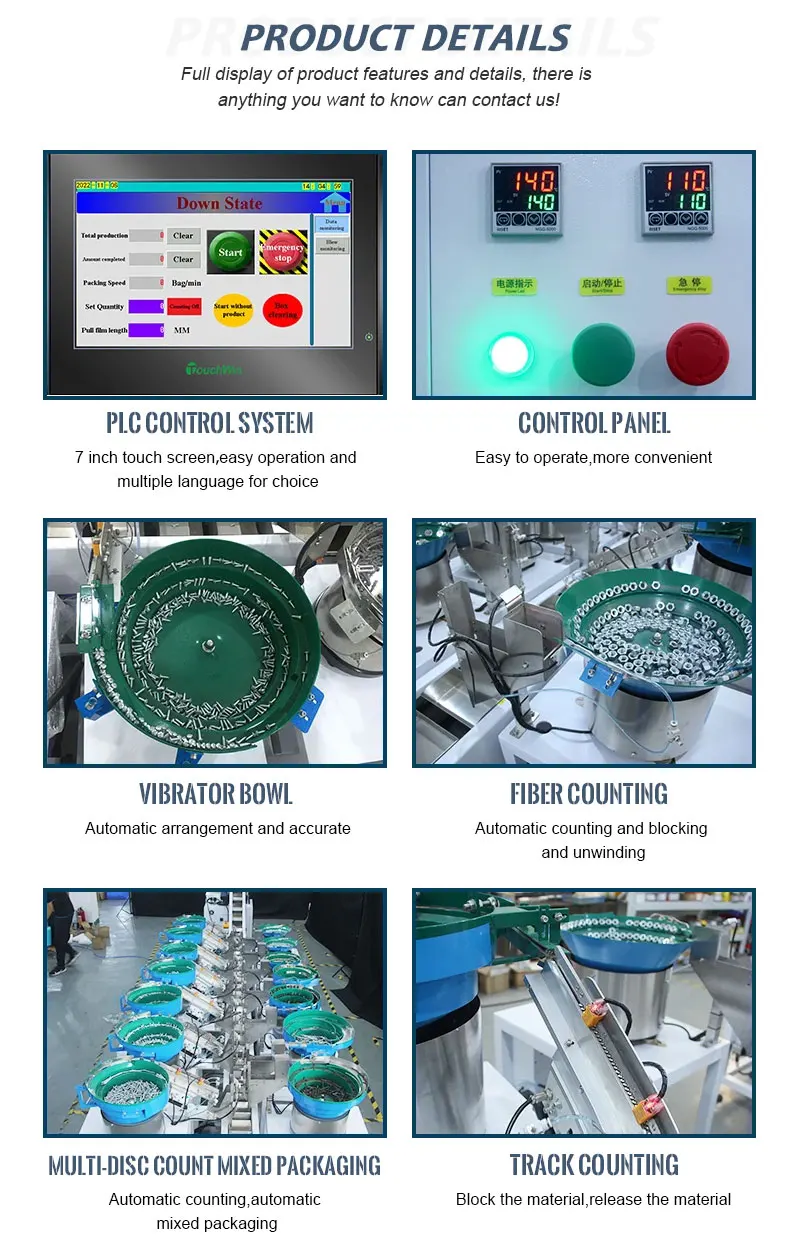

The machine can operate from 1 to 60 bags per minute, with a typical production capacity of up to 60 bags/min under optimal conditions.

2. What bag sizes can this machine handle?

It handles bag widths from 40 mm to 140 mm and bag lengths up to 200 mm (140 mm is the conventional length supported).

3. Which sealing types are supported?

The machine supports stripe seal, back seal, and three-side seal configurations. Back seal is the most commonly used option.

4. Is the machine fully automatic or does it require manual intervention?

The machine is fully automatic for film forming, filling and sealing. However, the described model uses a manual counting/feeding method where operators place items/bags manually. Automated feeding systems can be discussed as OEM/ODM options.

5. What power and air supply requirements are needed?

Electrical requirement: 220V, 50Hz, power 0.6 kW. Compressed air: 0.4–0.8 MPa. Ensure stable electrical supply and a dry, regulated air source.

6. What are the machine dimensions and weight?

Dimensions: L1100 mm x W750 mm x H1550 mm. Weight: approximately 100 kg.

7. Which industries and product types is this machine suitable for?

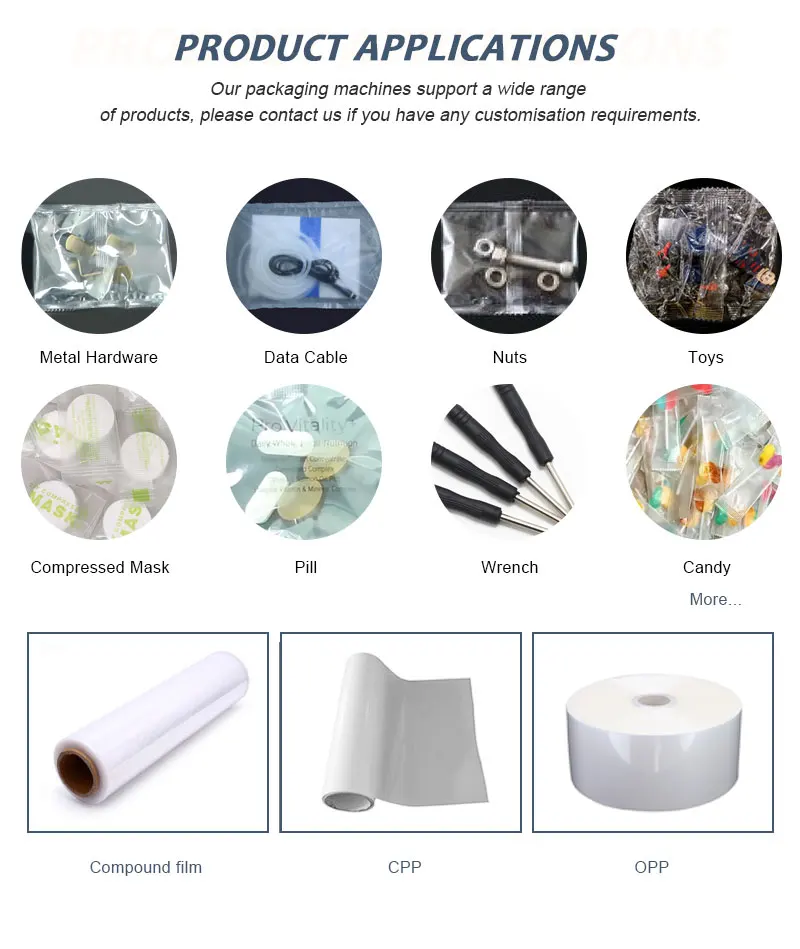

It is multipurpose and suitable for food, beverage, commodity, machinery & hardware and other industries that use flexible film bags and small to medium-sized items.

8. What bag mouth shape does the machine produce?

The machine uses a figure-cutter (toothed) mouth shape for the bag opening/seal edge.

9. What core components are used and are spare parts available?

Core components include motor, PLC, bearings, solenoid valve and cylinders. Spare parts and replacement components are available—contact sales for brands, lead times and pricing.

10. What warranty and after-sales support are provided?

The machine comes with a 1-year warranty covering manufacturing defects. Warranty typically excludes consumables, wear parts and damage from misuse. After-sales support, technical guidance and spare parts supply are available—contact us for service terms.

11. Is the machine tested before shipment?

Yes. A machinery test report is provided and a video of the outgoing inspection is available to show the machine operating correctly prior to shipment.

12. Can the machine be customized or integrated into an existing production line?

Yes. OEM/ODM customization is offered. We can adapt feeding systems, sealing types, electrical configurations and controls to integrate with existing lines—contact us with your requirements.

13. What bag materials are compatible?

The machine is compatible with common flexible packaging films (PE, PP and laminate films). For specialty films, barrier laminates or unusual thicknesses, please provide samples for compatibility testing.

14. What basic maintenance is required to keep the machine running reliably?

Regular visual inspection, daily cleaning of film paths and sealing areas, periodic lubrication of moving parts, checking and tightening belts/screws, and routine inspection of sensors, pneumatics and electrical connections. Replace wear parts (sealing bars, cutters) as needed.

15. How do I get pricing, lead time and shipping information?

Contact our sales team with your required machine configuration, order quantity and destination. Lead time depends on configuration and order size; machines ship from Guangdong, China. We will provide a quotation, estimated lead time and shipping options.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading