B21, China Town Mall, Midrand

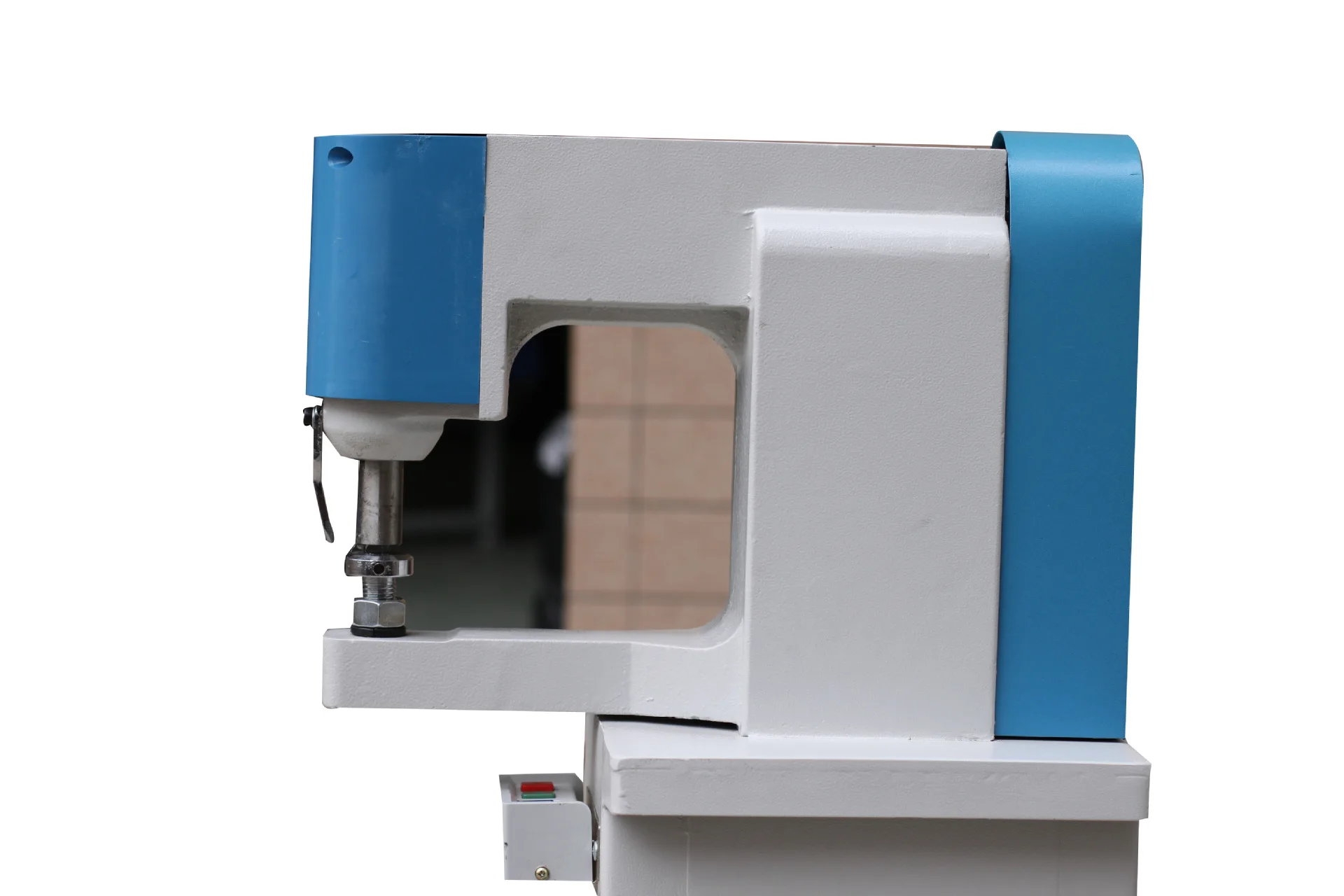

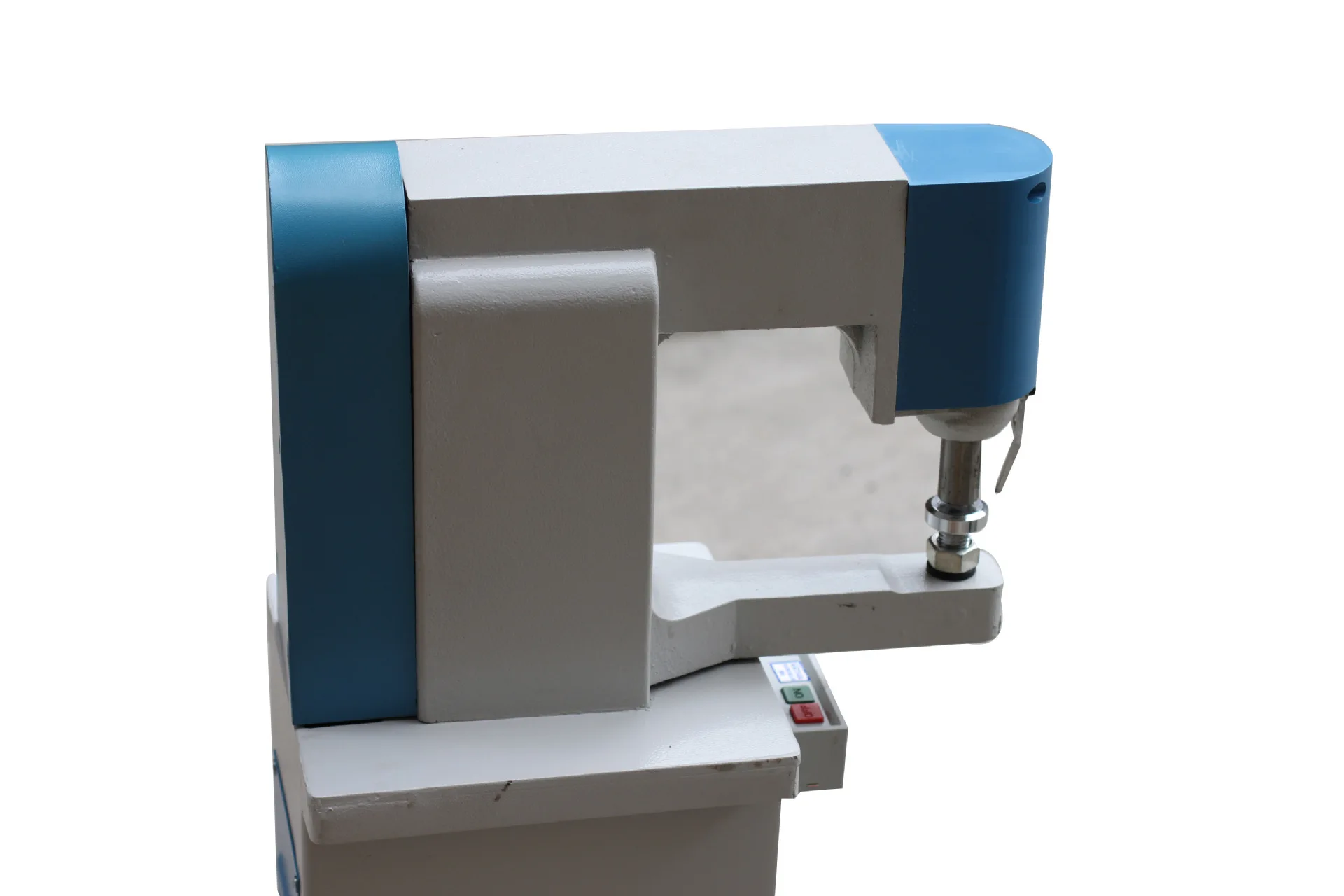

Automatic Hydraulic Rubber Leather Shoes Manufacturing Side Heel Seat Lasting Making Machine

- Section : Machinery

- Category : Shoe Making Machines

- SKU : 1600965188990

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

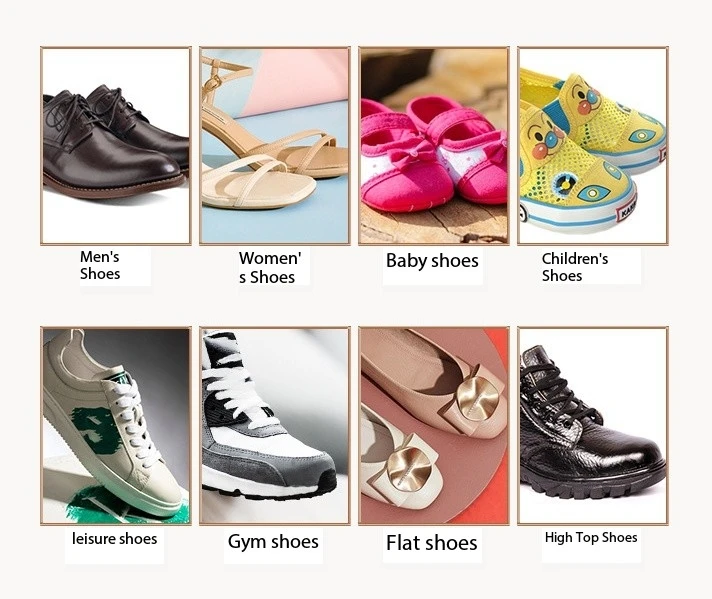

1. What types of shoes can this machine manufacture?

The Automatic Hydraulic Rubber Leather Shoes Manufacturing Side Heel Seat Lasting Making Machine is suitable for manufacturing both rubber and leather shoes, including various styles of footwear.

2. What is the voltage requirement for this machine?

The machine operates on an AC voltage of 220V.

3. What are the dimensions of the machine?

The machine has dimensions of 750mm in length, 750mm in width, and 1650mm in height.

4. How much does the machine weigh?

The machine weighs 200 kilograms.

5. What is the warranty period for this machine?

The machine comes with a warranty period of 3 years.

6. What kind of after-sales service is provided?

After-sales services include free spare parts, field maintenance and repair service, video technical support, and online support.

7. How does the hydraulic system improve shoe production?

The hydraulic system ensures precise and consistent results in the lasting process, which enhances the overall quality of the shoes produced.

8. Is this machine suitable for small-scale production?

While it is designed for large-scale shoe production facilities, its compact size makes it suitable for small-scale production and custom shoe making as well.

9. Can this machine be integrated into existing production lines?

Yes, the compact size of the machine allows for easy integration into existing shoe manufacturing production lines.

10. What are the key features of this machine?

Key features include automatic operation for efficient production, a hydraulic system for precision, a robust design for durability, and comprehensive warranty and support services.

11. Is training provided for using this machine?

Training is typically provided as part of the after-sales support, ensuring operators can effectively use the machine.

12. Can this machine handle custom shoe designs?

Yes, the machine is ideal for custom shoe making, allowing for various styles and designs.

13. What kind of maintenance does the machine require?

Regular maintenance is recommended, and field maintenance along with repair services are provided as part of the after-sales support.

14. How does the machine contribute to production efficiency?

The automatic operation and hydraulic system of the machine streamline the lasting process, significantly enhancing production efficiency.

15. Are spare parts readily available for this machine?

Yes, spare parts are provided free of charge as part of the after-sales service.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading