B21, China Town Mall, Midrand

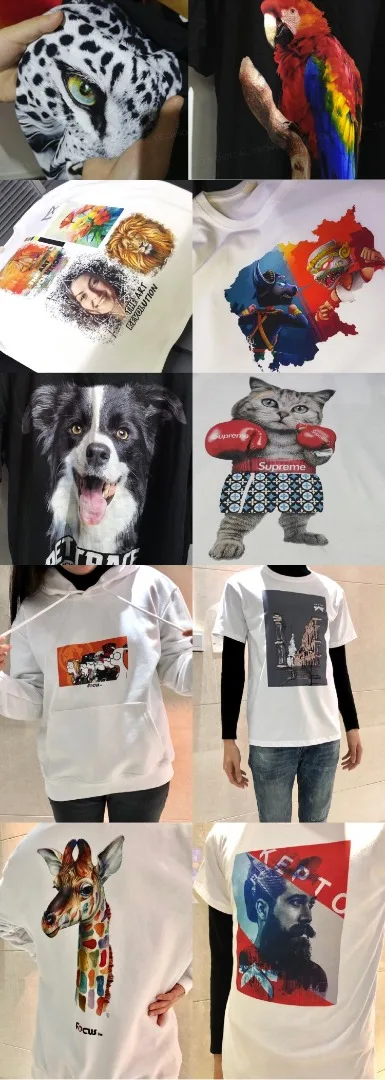

A3 digital dtg printer shopping bag printing machine with 2 heads

- Section : Consumer Electronics

- Category : DTG Printers

- SKU : 60574715024

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 30 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum printable area for the A3 Digital DTG Printer?

The maximum printing size is up to 355 mm x 500 mm (A3), suitable for most large shopping bags and similar items.

2. What substrates and shopping bag materials can this printer print on?

This printer is designed primarily for textile-style bags (cotton, canvas, blends, and many non-woven fabrics). It can also work with other suitable substrates if the correct ink type and pretreatment are used. Always perform a test print and follow ink/pretreatment manufacturer recommendations for best results.

3. What ink types are compatible with the machine?

The printer is compatible with Eco solvent ink, Textile ink, CTS ink, Edible ink, and Discharge ink. Choose the ink type appropriate to your substrate and application and verify any food-safety requirements if using edible ink.

4. How are the printheads configured and what does '2 heads' mean?

The machine has a dual-head configuration. It uses a 12-color setup where one head handles the color channels (including CMYK and additional color channels) and the second head is dedicated to white ink for underbase and enhanced detail/depth.

5. What printing resolutions and speeds does the printer support?

Maximum supported resolutions are 2880 DPI, 1440 DPI, and 720 DPI. At 1440 DPI the printer can produce an A3 print in approximately 64 seconds; lower resolutions print faster with reduced detail.

6. Does the printer support printing on dark-colored bags?

Yes. The dedicated white-head lets you print an underbase or highlights on dark substrates. For best opacity and durability on dark materials, use the appropriate white ink and a recommended pretreatment process.

7. How is height adjustment handled for different bag thicknesses?

The printer offers both automatic and manual height adjustment, allowing precise control for items up to 16 cm in height.

8. What are the printer's physical limits for object weight and dimensions?

Maximum supported object height is 16 cm and the printer can accommodate items up to 80 kg. Overall printer dimensions are 90 cm x 91 cm x 51 cm; shipping size is 105 cm x 100 cm x 75 cm.

9. What are the ink tank capacity and replenishment details?

Each ink tank holds 250 mL to allow extended printing runs. Use manufacturer-recommended inks and refill procedures; maintain spare tanks and follow purge/priming instructions to avoid nozzle issues.

10. What connectivity and software/OS compatibility does the printer have?

The printer connects via USB2.0 or LPT and is compatible with Windows 7/8/10. For RIP/print management software, confirm with the vendor which packages are supported or supplied.

11. What are the environmental and power requirements?

Operating environment: 10–35°C and 20–80% RH. Power requirements are 110–220V, 50–60 Hz with typical power consumption of 75W.

12. How do I cure prints after printing and ensure wash/durability?

Curing/fixing depends on the ink type used. Typically DTG/textile inks require heat curing using a heat press or conveyor dryer. Follow the ink manufacturer's recommended curing temperature and time for optimal durability; contact the supplier for recommended cure settings for your chosen ink.

13. What maintenance is required and how do you protect the printheads?

Routine maintenance includes daily or scheduled head cleaning cycles, keeping the capping station/nozzles clean, and following recommended flushing and ink-replacement practices. The printer includes an Intelligent Self-Protect System to help preserve printhead life, but regular maintenance and using quality inks are essential.

14. Is training, spare parts, or warranty support available?

Specifics on training, spare parts availability, and warranty vary by supplier. Contact the seller or distributor for details on included warranty, available service plans, spare parts (printheads, pumps), and training options.

15. How do I order or get more technical information before purchasing?

For pricing, lead times, consumables, technical datasheets, and live demos, please contact the vendor or sales representative. They can provide sample prints, recommended inks/pretreatments, and any regional service/support information.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading