B21, China Town Mall, Midrand

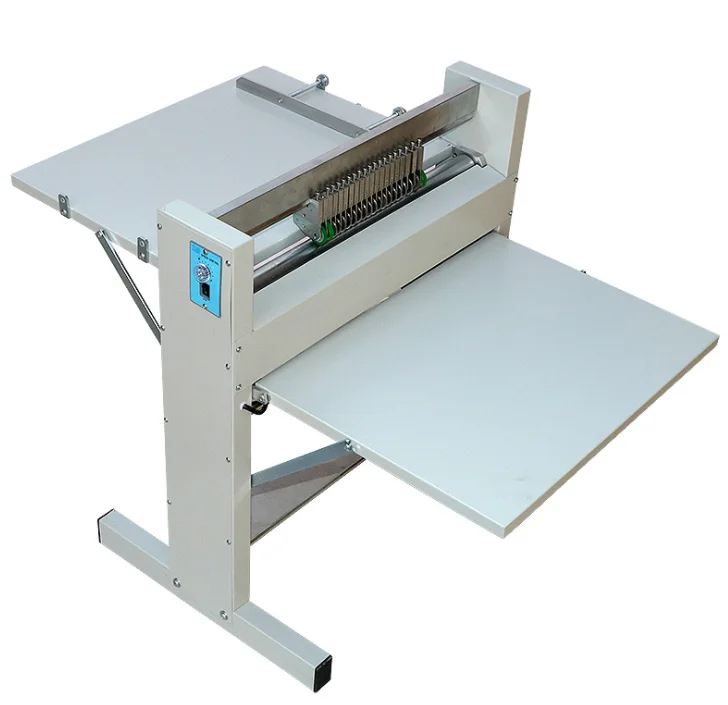

A3 A4 Automatic Die Cutting Machine;Half Label Cutting Machine

- Section : Machinery

- Category : Machine Tool Equipment

- SKU : 60751985319

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 04 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What models are available and how do they differ?

The machine is available in four models: XX-300, XX-400, XX-500 and XX-600. They differ mainly in maximum cut width and feed table size: MAX cut widths are 300mm, 400mm, 500mm and 600mm respectively, and paper feed tables are 340×240mm, 440×240mm, 540×240mm and 640×240mm. Overall external sizes also vary by model.

2. What materials can this die cutting/half-label cutting machine handle?

It's designed primarily for adhesive rolls, label stock and common printing/packaging papers. It can also perform slitting, dotted cutting and rolling folding lines. For unusual substrates or very thick media, check with the supplier for compatibility.

3. What are the key cutting and speed specifications?

Key specs: roller rotational speed 50–300 rpm, linear working speed 5–60 m/min (depending on material and setup). Maximum paper width depends on model (up to 600mm for XX-600). Blade minimum clearance can reach 5mm with correct setup.

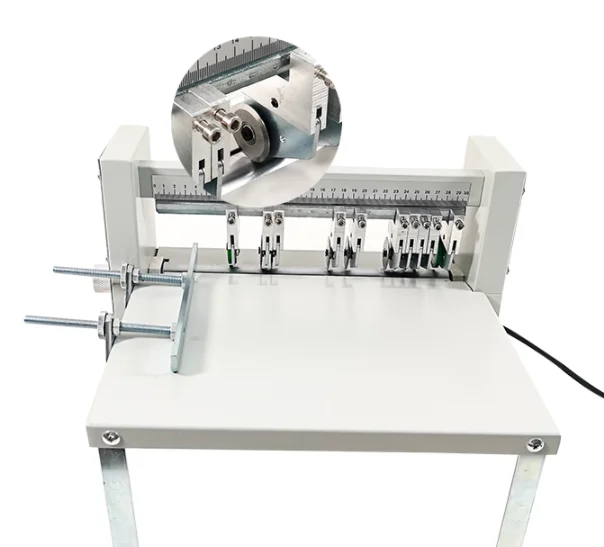

4. What is the minimum distance between cutting blades?

The machine can achieve a minimum tool/blade clearance of 5mm with proper speed and setup. Typical recommended blade-to-blade distances are in the 10–15mm range for most operations to ensure reliable cutting.

5. How easy is it to install or change the blade?

The blade is designed for easy installation and replacement. The product highlights quick blade mounting and safe operation. Always follow the manual for correct alignment and secure fastening, and power off the machine before changing blades.

6. How do I adjust cutting pressure for different papers?

The machine includes an adjustable pressure mechanism. Increase pressure for thicker or denser papers and reduce it for thin or delicate substrates. Make incremental adjustments and run test cuts until the desired quality is reached.

7. What spare parts are commonly needed and available?

Common spare parts include cutting blades (round/razor), rubber rollers, bearings, drive belts, and fast-wearing hardware. The description mentions rubber roller assemblies and related components — contact your supplier for a full spare-parts list and part numbers.

8. What routine maintenance is recommended?

Regular maintenance includes cleaning the blade and feed areas, inspecting and replacing worn blades and rubber rollers, lubricating bearings as specified by the manual, checking belt tension and alignment, and verifying sensor and electrical connections. Perform more frequent checks under heavy use.

9. What should I do if cuts are uneven or misaligned?

Common causes are blade wear, incorrect blade alignment, improper rubber roller tangency, incorrect pressure or uneven material feed. Check blade sharpness and alignment, ensure the rubber wheel runs smoothly and is correctly positioned, adjust pressure and feed speed, and confirm the material is loaded straight.

10. Can the machine creases or flattens adhesive labels?

Yes. The rubber roller assembly can be used for paper creasing or adhesive flattening as noted in the instructions. Proper roller installation and pressure settings are required for best results.

11. Is the machine suitable for high-volume production?

With skilled operation and correct setup, the machine can achieve high yield and quality. Working speed up to 5–60 m/min and roller speeds up to 300 rpm support moderate-to-high throughput; expected production depends on substrate, cut complexity and operator skill.

12. What safety features or precautions should I follow?

Follow standard machine-safety practices: disconnect power before maintenance or blade changes, keep hands away from moving parts, use guards provided, wear appropriate PPE, and follow the operation manual. Ensure emergency stop functions are working before production runs.

13. Where can I find electrical and installation specifications?

Electrical supply and detailed installation requirements are not listed in the summary. Contact the manufacturer or supplier for the machine's power rating, wiring diagram, floor/space requirements and any site preparation instructions.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading