B21, China Town Mall, Midrand

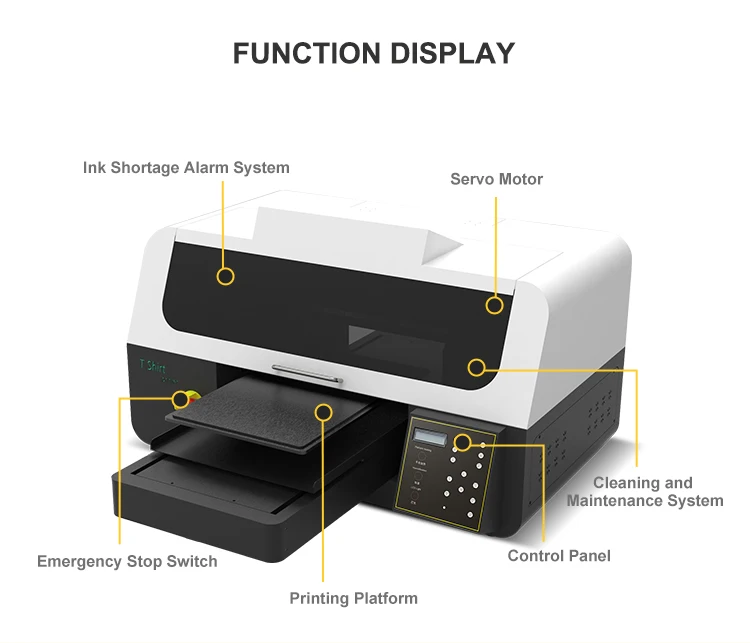

A2 DTG Printer T-Shirt Printing Machine – Fabric Printing for Apparel

- Section : Consumer Electronics

- Category : DTF Printers

- SKU : 1600774789847

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum print size of the A2 DTG Printer?

The printer supports up to A2 size (400 x 600 mm / 40 x 60 cm), suitable for larger designs and multiple print placements on a single platen.

2. Which fabrics and products can this DTG printer print on?

It is designed for T-shirts, sweaters, sportswear, denim, chiffon, silk, pillows and other fabric-based items. Some fabric types may require pretreatment for best results.

3. What print resolutions are available?

The machine supports 720 dpi, 1080 dpi and 1440 dpi, allowing you to select the best balance of speed and detail for each job.

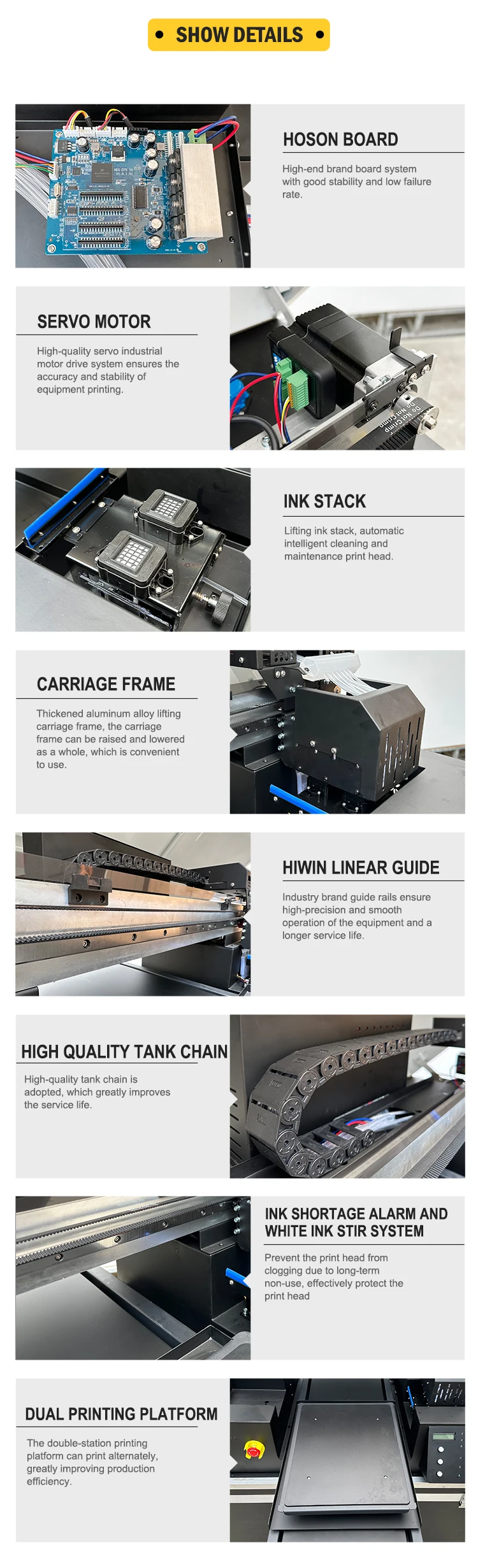

4. What print heads does the machine use and how many are installed?

The unit ships with two print heads (models listed include XP600 and I3200 variants), providing faster throughput and redundancy for more reliable production.

5. Does the printer support white ink and how is clogging prevented?

Yes — the printer features white ink with automatic circulation/stirring and white-ink management to minimize settling and prevent clogging, plus automatic head cleaning routines.

6. What type of ink does the A2 DTG Printer use?

The specification lists UV textile ink. Confirm with your supplier for the exact ink formulation recommended for your intended substrates and post-print curing method.

7. Which RIP/software and file formats are supported?

The printer is compatible with popular RIP software such as MainTop (Maintop) and PhotoPrint. It accepts common print files (PNG, TIFF, JPEG, PSD) — use PNG/TIFF with transparent backgrounds for garment artwork and consult your RIP for color/ICC profile settings.

8. What are the typical print speeds?

Print speed depends on print head and settings. Typical speeds noted are: XP600-2: ~180 seconds per A2 print (1 pc) and I3200-2: ~100 seconds per A2 print (1 pc). Higher resolutions will take longer.

9. How is the garment held in place during printing?

The machine includes a platen with platform suction to secure garments flat and stable during printing for accurate, repeatable results.

10. What are the machine dimensions, weight and packaging size?

Machine size: L950 x W1080 x H500 mm; weight: 84 kg. Package size: L1050 x W1180 x H700 mm; packaged weight: 98 kg.

11. What power and environment conditions does the printer require?

Rated power is 500 W and the unit supports 110 V and 220 V operation. Recommended operating environment: temperature 15–30°C and relative humidity 40–60%.

12. What connectivity and operating systems are supported?

The printer provides a Gigabit Ethernet print interface and works with Windows platforms (XP, Windows 7, Windows 10) through supported RIP software.

13. What maintenance is required and how do I clean print heads?

Daily/weekly maintenance typically includes running automatic head cleaning cycles, checking/ topping ink cartridges, and ensuring white ink circulation. Detailed maintenance schedules and procedures should be followed from the user manual; replace print heads or cartridges as recommended.

14. Is pretreatment or curing required for printing on dark garments?

Yes — dark garments usually require a pretreatment solution to ensure white ink adhesion and vibrancy. After printing, garments must be cured (heat press or conveyor dryer) according to the ink manufacturer’s instructions.

15. What warranty and technical support are provided?

Core components are covered by a 1-year warranty. For installation, training, consumables and ongoing technical support, contact your supplier or manufacturer; many vendors provide remote support and optional on-site service.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading