B21, China Town Mall, Midrand

400-500kg/h Complete Pet Food Automatic Machine Processing Line, Dog Feed Pellet Making Extrusion Extruder

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600525608642

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of dog food can be produced with this machine?

The Complete Pet Food Automatic Machine Processing Line can produce various types of dog foods, including those made from animal proteins like fish meal and chicken meal, as well as plant proteins such as corn flour, rice flour, and soybean flour.

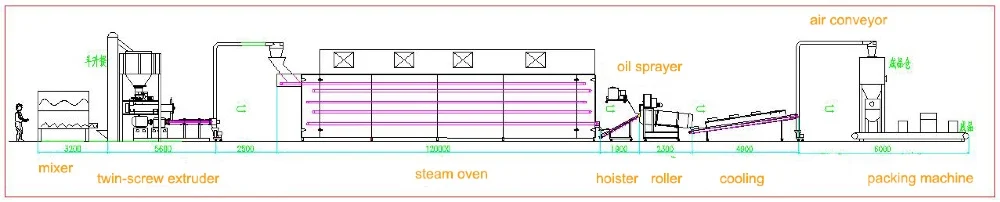

2. What is the production flow for the dog food processing line?

The production flow includes several steps: Milling Machine → Mixer → Conveyor → Extruder → Conveyor → Dryer → Conveyor → Flavoring Machine → Cooling Machine → Lifter Packing Machine.

3. Can the machine be customized for different shapes of dog food pellets?

Yes, the machine comes with customizable molds that can be designed according to the specific shape requirements of the customer's desired products.

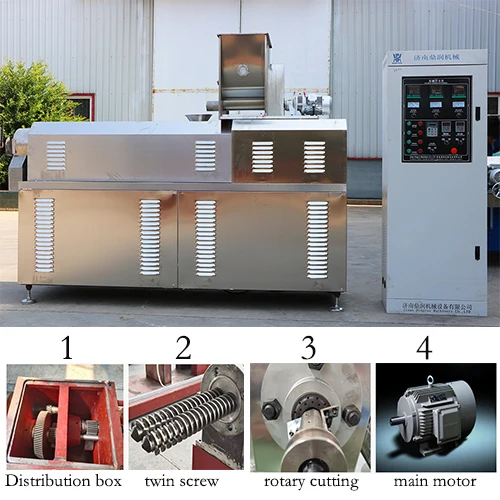

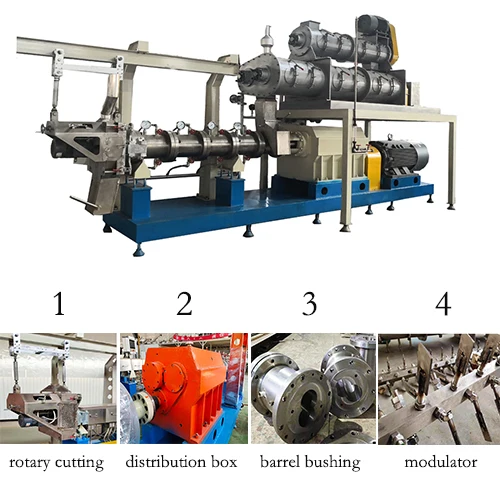

4. What are the main components of the dog food machine?

The main components include a twin screw extruder, dryers, flavoring machines, cooling machines, and a packing machine, all designed to process and produce high-quality dog food.

5. What are the power requirements for the different models of the extruder?

Power requirements vary by model. For example, the DSE65 model requires 74.5 kW, while the DSE120 model requires 469 kW. Each model has different power consumption and capacity.

6. What are the dimensions of the processing line?

The dimensions vary by model. For instance, the DSE65 has dimensions of 17*1.2*2.2 meters, while the larger DSE135 model is 50*20*25 meters in size.

7. Is the machine easy to clean and maintain?

Yes, the machine features a design that allows for easy cleaning, including alloy material screws and adjustable cutting mechanisms, which simplify maintenance.

8. What is the capacity of the dog food production line?

The capacity ranges from 120-180 kg/h for the DSE65 model to 3000-3500 kg/h for the DSE135 model, depending on the specific machine used.

9. What materials are used in the construction of the extruder?

The extruder is made from high-quality materials, including a barrel of No. 45 steel with wear-resistant bushings, ensuring durability and a long service life.

10. What are the benefits of using a twin screw extruder?

Twin screw extruders provide better mixing, more efficient cooking, and enhanced texture control, allowing for high-quality pet food production.

11. How does the flavoring machine work?

The flavoring machine applies flavoring agents to the dog food pellets after they have been cooked and dried, enhancing the taste and appeal of the final product.

12. What is the role of the dryer in the production line?

The dryer removes moisture from the dog food pellets, ensuring they have the right consistency and shelf life. This step is crucial for preventing spoilage.

13. Can I see samples of the final product?

Yes, samples of the final product can be provided upon request. This will give you an idea of the types of dog food pellets that can be produced.

14. What is the warranty and support provided with the machine?

Warranty details and support services vary by manufacturer. It's best to check with the supplier for specific warranty terms and after-sales support.

15. Is training available for operating the machine?

Typically, suppliers offer training for operating the machine as part of the purchase, ensuring that your staff can efficiently use the equipment.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading