B21, China Town Mall, Midrand

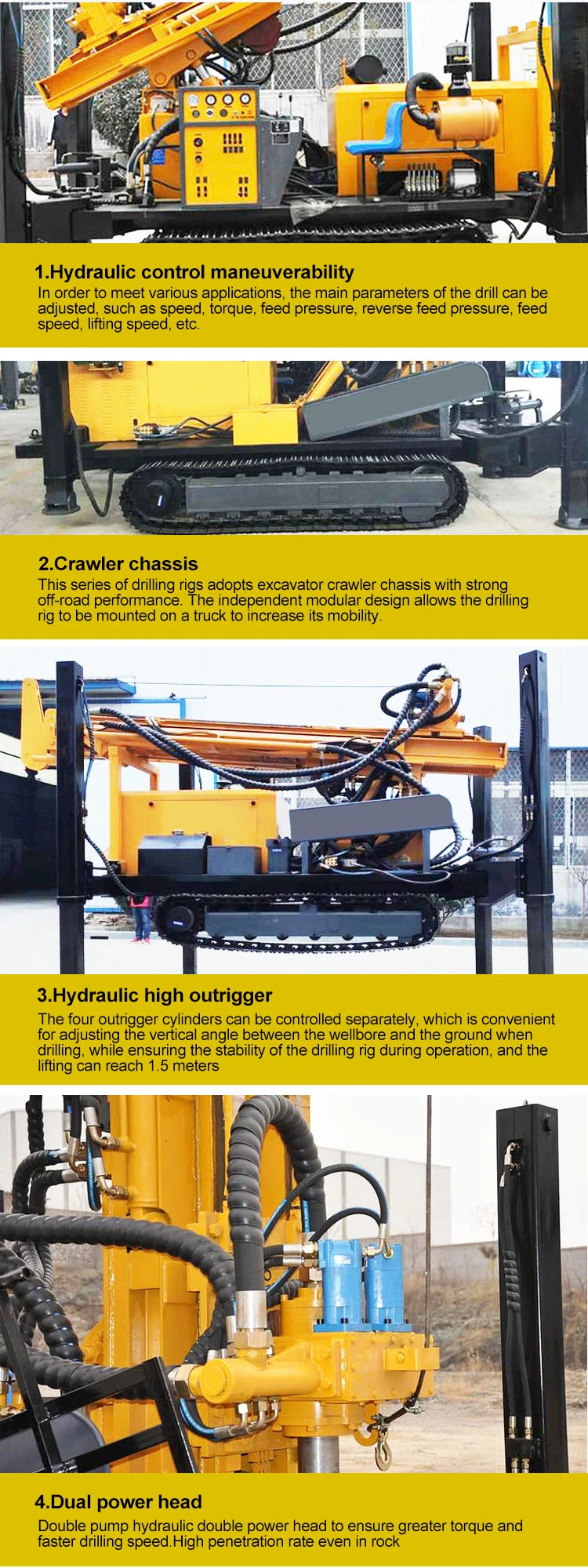

300m Deep Crawling Well Water Core Drilling Machine

- Section : Machinery

- Category : Mining Machinery

- SKU : 1600718042301

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 11 Apr, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum drilling depth of the 300m Deep Crawling Well Water Core Drilling Machine?

The rig is capable of drilling to a maximum depth of 300 meters, making it suitable for deep water wells and core sampling work.

2. What drilling diameters does this machine support?

Standard drilling diameters range from 100 mm to 219 mm, with an optional 300 mm configuration available to meet larger bore requirements.

3. What type of engine powers the drilling rig?

The machine is driven by a CHANGCHAI diesel engine, providing continuous, strong power output for demanding drilling operations.

4. Is the rig mobile and suitable for remote or rugged sites?

Yes. The rig features a Crown Move crawling mobility system that enables relocation across rough or constrained job sites so you can drill in remote or difficult-to-access locations.

5. What is the weight of the drilling machine and how easy is it to transport?

The rig weighs approximately 7,200 kg. Its compact, lightweight design helps simplify transport and on-site maneuvering; typical transport is by flatbed truck or trailer—confirm local transport regulations and lifting equipment capacity.

6. Does the machine require an external power source?

No external electrical power is required for drilling—the integrated diesel engine powers the hydraulic and pneumatic systems needed for operations.

7. What drilling conditions and ground types can this rig handle?

The rig is designed for water-well drilling, borehole core sampling, and pneumatic rock drilling. Its hydraulic system and pneumatic rock drill make it capable of handling a wide range of soil and rock formations, including hard rock, depending on bit selection and drilling parameters.

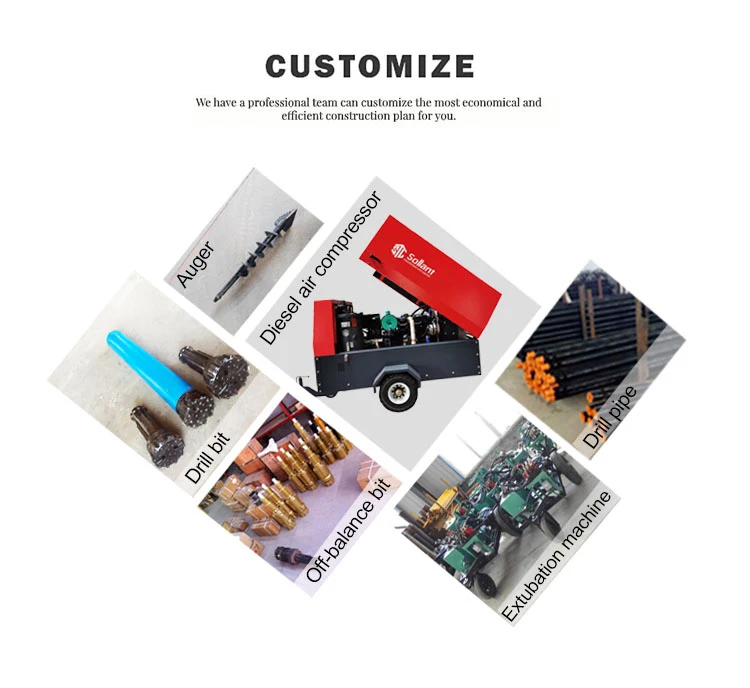

8. What core sampling and bit options are compatible with the machine?

The rig accepts standard core barrels, drill rods, and a variety of bits (diamond, PDC, TCI/roller, etc.) depending on the formation and hole size. Contact the supplier for recommended core and bit configurations for your project.

9. What kind of maintenance and service does the rig require?

Routine maintenance includes daily inspections, engine oil and filter checks, hydraulic fluid level and filter monitoring, greasing of moving parts, checking drill bits and rods, and scheduled servicing per operating hours. Follow the manufacturer's maintenance schedule for optimal performance.

10. Is after-sales support available?

Yes. The product includes comprehensive online after-sales support for installation, maintenance guidance, troubleshooting, and parts ordering. Local dealer support may also be available depending on your region.

11. What safety features or precautions should operators follow?

Operators should follow standard drilling safety practices: use required PPE (helmets, gloves, eye and hearing protection), secure the rig on stable ground, follow lockout/tagout procedures for maintenance, observe hydraulic and high-pressure safety protocols, and comply with local regulations and operator training requirements.

12. What is the expected drilling efficiency or penetration rate?

Penetration rates vary widely depending on formation, bit type, drilling fluid, and operator technique. The rig's hydraulic system and pneumatic rock drill are optimized for high efficiency, but for project-specific rates, request performance data or field references from the supplier.

13. Are spare parts and consumables available for this model?

Yes. Spare parts and common consumables (bits, core barrels, seals, filters, etc.) are available—contact the manufacturer or authorized reseller to order parts and confirm lead times for your region.

14. Does the manufacturer provide training for operators?

Training availability varies by supplier and region. The manufacturer offers online support and can arrange operator training, commissioning assistance, or on-site instruction—contact your sales representative for options and scheduling.

15. What warranty or guarantees come with the drilling machine?

Warranty terms and coverage depend on the seller and your location. For specific warranty length, conditions, and included services, contact the supplier or authorized dealer for the official warranty policy and any available extended-care options.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading