B21, China Town Mall, Midrand

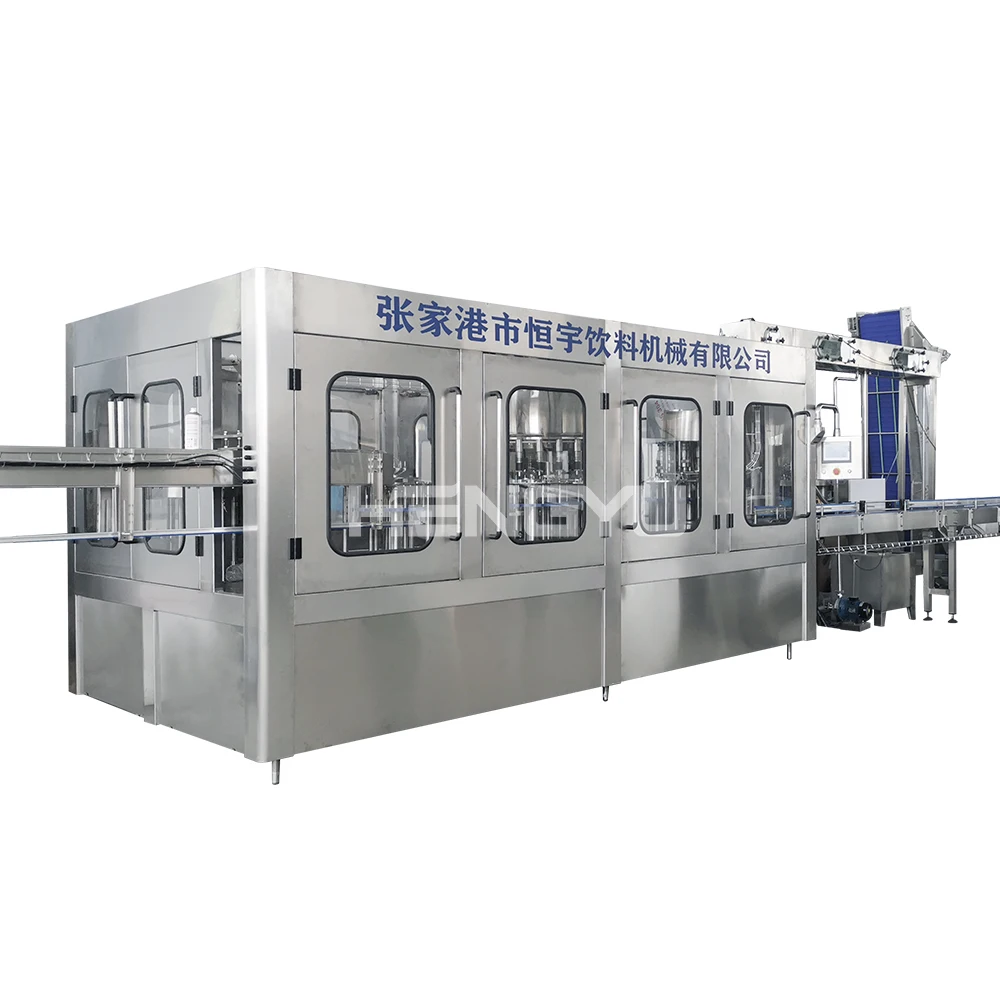

3 in 1 Automatic Production Plant Line Bottle Capping Packing

- Section : Machinery

- Category : Manufacturing Machinery

- SKU : 62351861266-1723123004

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of bottles can the 3 in 1 Automatic Production Plant Line handle?

The machine can handle PET bottles, glass bottles, pop cans, 3-5 gallon containers, and 3-10L barrels.

2. What is the production capacity of the machine?

The production capacity is up to 12,000 bottles per hour at 500ml.

3. Is the machine suitable for different bottle sizes?

Yes, it features a design that allows for quick changeover between different bottle types and sizes with minimal adjustments.

4. What materials are used in the construction of the machine?

The machine is constructed with high-quality 304/316 stainless steel for parts in contact with water, ensuring durability and hygiene.

5. How does the filling process work?

The filling process uses an advanced gravity filling principle for fast, stable, and accurate filling without dead corners.

6. What safety features does the machine have?

It includes cover missing and overload protection alarms, ensuring high production automation and safety.

7. Can the machine handle non-liquid products?

No, this machine is specifically designed for liquid products such as water, beverages, and other similar liquids.

8. What is the power requirement for the machine?

The power requirement varies depending on the model, ranging from 2.2 kW to 11.2 kW.

9. Does the machine require a special operator certification?

While specialized training is beneficial, a general understanding of machine operation and safety protocols is usually sufficient.

10. What type of control system does the machine use?

The machine uses a man-machine interface with touch screen buttons and PLC computer control for easy operation.

11. Is there a maintenance schedule for the machine?

Regular maintenance is recommended, including cleaning and inspection of all components, with specific schedules depending on usage.

12. Can I integrate additional equipment with the production line?

Yes, the machine can be integrated with various auxiliary equipment like bottle blowers, labelers, and packing machines.

13. What is the defective rate for capping?

The capping effect is stable and reliable, with a defective rate of less than 0.2%.

14. How does the machine ensure cleanliness during the washing process?

It uses 304/316 stainless steel rinse heads with a water spray design that minimizes water consumption while ensuring thorough cleaning.

15. What happens if there are no bottles available for capping?

The machine is designed to automatically stop when there are no bottles present, preventing unnecessary operation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading