B21, China Town Mall, Midrand

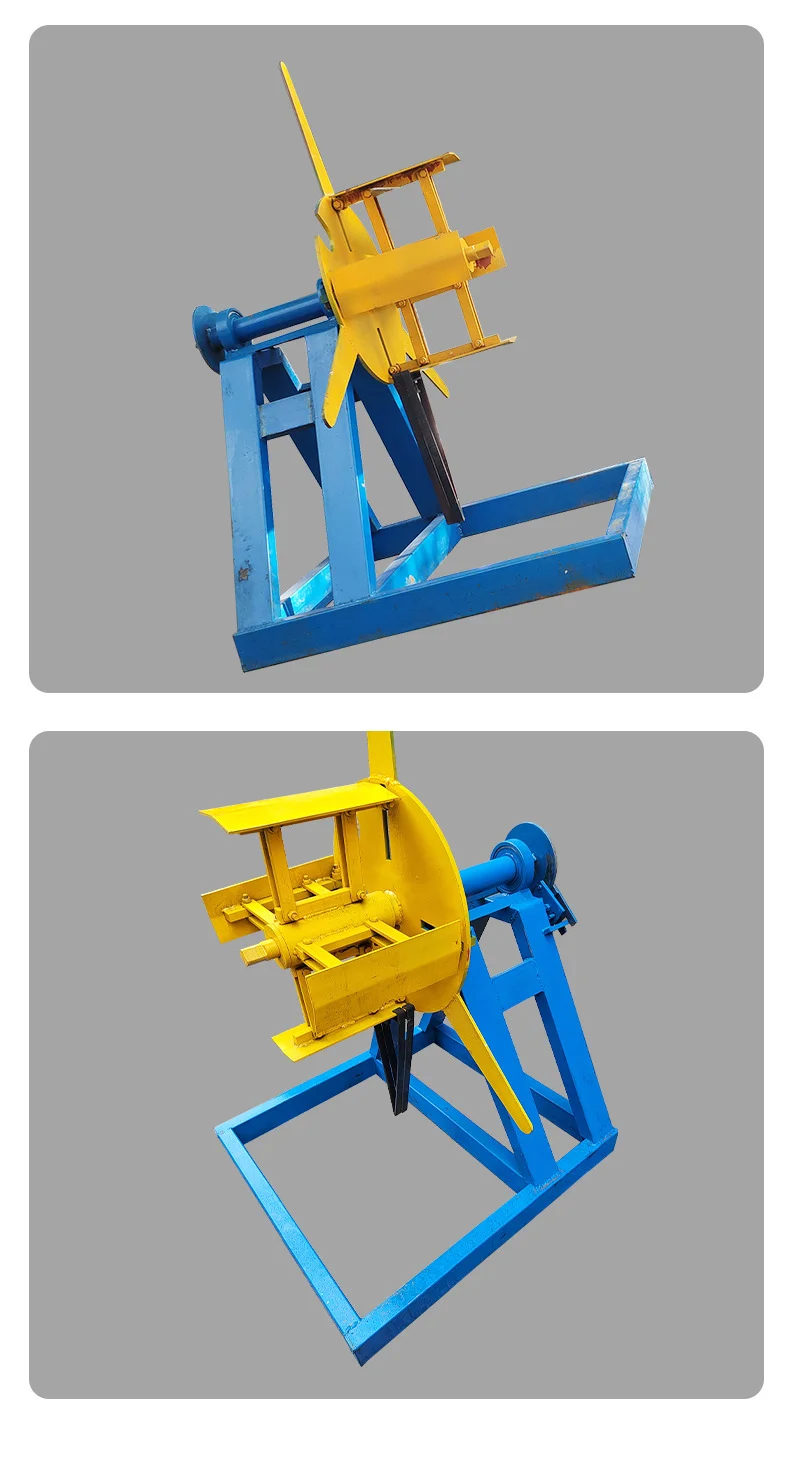

2 tons of retractable self-tightening material rack running fast full chrome steel full CNC mechanical equipment

- Section : Machinery

- Category : Tile Making Machinery

- SKU : 1601045326662

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the lifting capacity of this material rack?

This model is rated for a 2-ton (2000 kg) load capacity. Safe working loads and any derating for specific attachments are confirmed at order and in the product specification sheet.

2. What does "retractable self-tightening" mean?

The rack features a retractable structure that reduces its footprint when not in use and a self-tightening mechanism that automatically secures material during movement to minimize slipping and adjust to varying material thicknesses.

3. What materials and finish are used in construction?

The main structural and wear components are made of chrome steel (chrome-plated or chrome alloy steel) to provide improved wear and corrosion resistance and a long service life.

4. Is this equipment CNC controlled? What does "full CNC" imply?

"Full CNC" indicates that key manufacturing of components is done on CNC machines for precision, and the motion/control system is CNC-capable or PLC-driven for programmable, repeatable operation. Exact control hardware/software is configurable per customer requirements.

5. What dimensions (feeding width/length) does the rack support?

Feeding width, length, and piece measurements are customizable according to the customer's drawing or specifications. Provide your drawings or target dimensions so we can confirm compatibility and quote.

6. What industries is this equipment suitable for?

Typical applications include advertising, building materials, construction, energy & mining, farming, food & beverage, restaurants, hotels, machinery repair, manufacturing, printing, retail and other facilities requiring heavy-duty material handling.

7. What model or type is this product?

This listing is for model/type JB-25. Final configuration and features are confirmed during the quotation and drawing-approval process.

8. What are the electrical and power requirements?

Power requirements depend on the chosen drive and control options. Standard configurations typically use industrial three-phase power; exact voltage, current, and control-interface specifications will be provided after you select the desired configuration.

9. How is the product shipped and where does it originate?

The equipment ships from Zhejiang, China. We offer export-ready packaging and multiple shipping options (sea, air, or land). Shipping terms (FOB/CIF/DDP) can be arranged per your preference.

10. What is the typical lead time and delivery timeline?

Lead time depends on customization and order size. After drawing and specification approval, typical manufacturing lead times range from several weeks to a few months. We will provide a firm delivery schedule with your quotation.

11. What installation, commissioning and training services are available?

We provide remote technical support, detailed installation manuals, and commissioning assistance. On-site installation, start-up and operator training can be arranged where necessary (may incur additional costs).

12. What maintenance is required and are spare parts available?

Routine maintenance includes lubrication of moving parts, periodic inspection of fasteners and tightening mechanisms, checking wear components, and keeping the unit clean. Spare parts are available; recommend stocking critical wear items per your usage profile.

13. What safety features are included?

Common safety features include emergency-stop circuits, overload protection, mechanical guards for moving components, and interlocks. Final safety equipment and guarding can be tailored to meet your local regulations and application needs.

14. Are certifications, warranty and after-sales support provided?

Warranty and after-sales support terms are included with the quotation; typical warranties cover manufacturing defects for a standard period (please request exact terms). Certifications such as CE, ISO, or others can be provided upon request and subject to configuration and testing.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals