B21, China Town Mall, Midrand

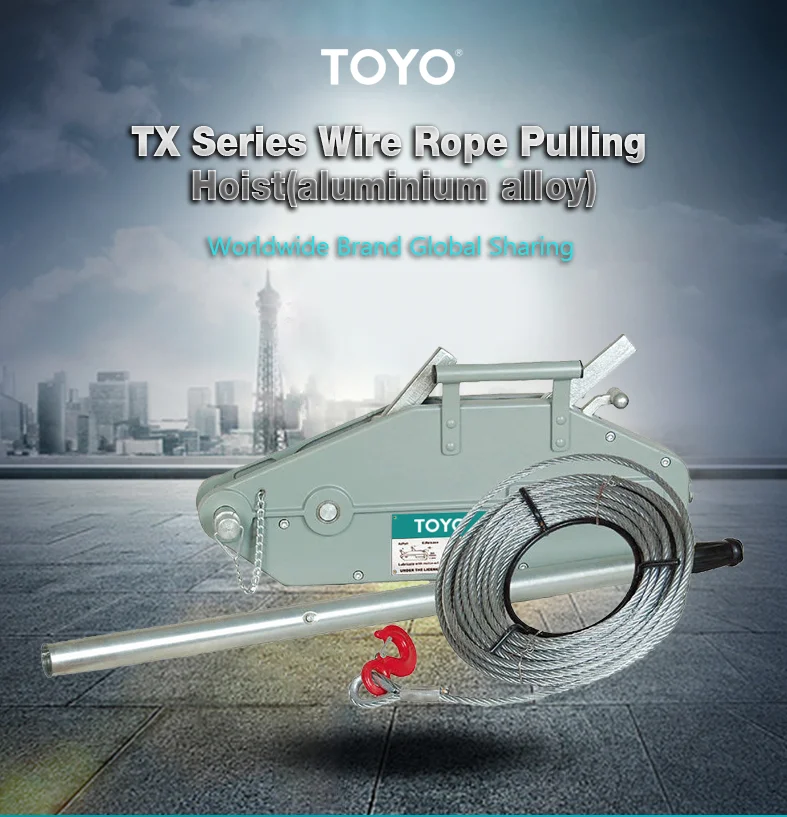

1.6 To 5.4 Ton Manual Wire Rope Push Pulling Lifting Leash Chain Block Hoist

- Section : Machinery

- Category : Hoists

- SKU : 62458315214

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 04 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the 1.6 To 5.4 Ton Manual Wire Rope Push Pulling Lifting Leash Chain Block Hoist?

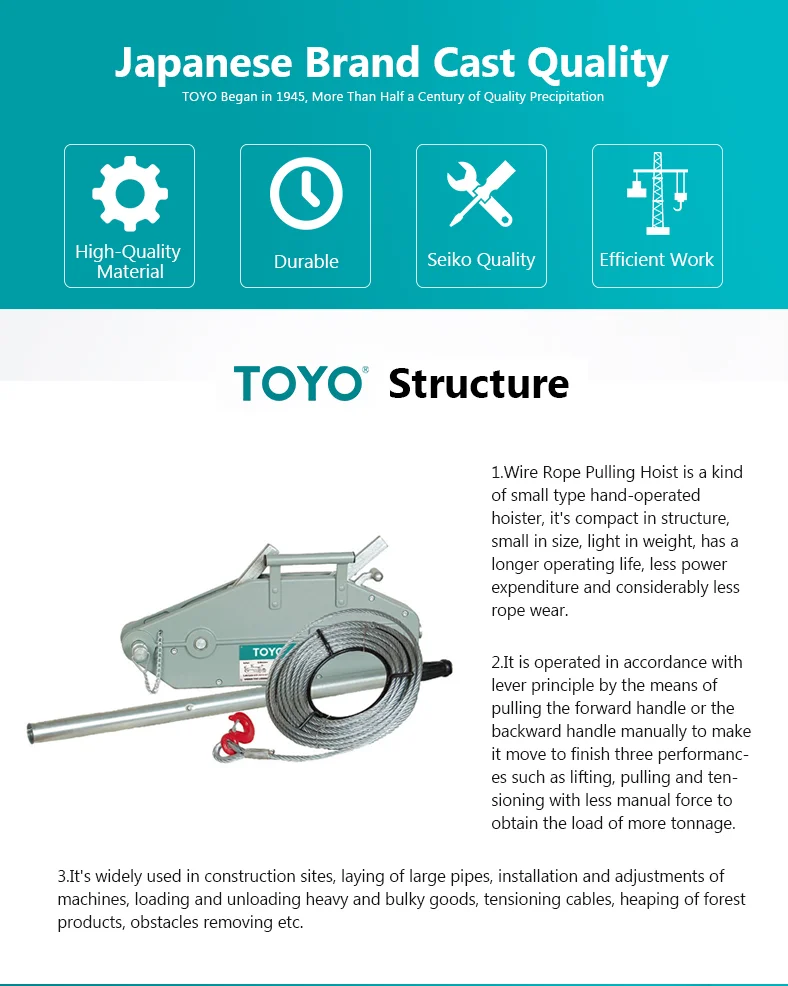

A manual wire-rope puller / Tirfor-style hand hoist available in multiple models (TX800, TX1600, TX3200, TX5400) designed for pulling and lifting applications where a portable, mechanical hand-operated solution is required.

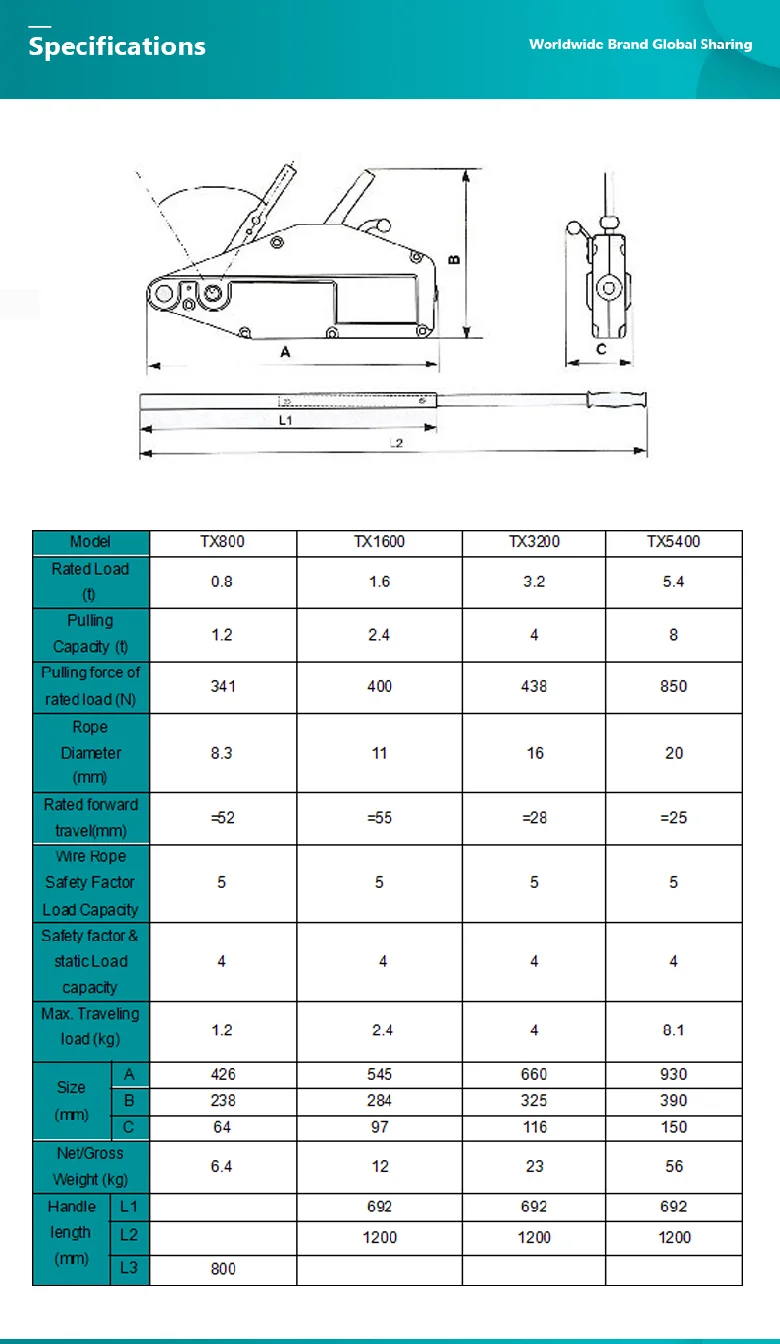

2. Which models are available and what are their rated loads?

Four models: TX800 (rated load 0.8 t), TX1600 (1.6 t), TX3200 (3.2 t) and TX5400 (5.4 t).

3. Is this hoist manually operated or powered?

It is a manually operated wire rope puller (hand-operated Tirfor / lever-action device).

4. What is the pulling capacity for each model?

Pulling capacity (as given in the product data) is approximately: TX800 — 1.2 t; TX1600 — 2.4 t; TX3200 — 4.8 t; TX5400 — 8.1 t. Pulling capacity is greater than the rated (lifting) load, but you should always choose the correct model and rigging for your application.

5. What are the wire rope diameters for the different models?

Rope diameters (per model) are approximately: TX800 — 8.3 mm; TX1600 — 11 mm; TX3200 — 16 mm; TX5400 — 20 mm.

6. What safety factors are specified for the wire rope and the unit?

The specification lists a wire rope safety factor of 5 (5:1). A separate safety/static load factor value is listed as 4 (4:1). Always apply safe working practices and never exceed rated loads.

7. What are the physical dimensions and weights of the models?

Dimensions by model (A / B / C in mm): TX800 — A 426 / B 238 / C 64; TX1600 — A 545 / B 284 / C 97; TX3200 — A 660 / B 325 / C 116; TX5400 — A 930 / B 390 / C 150. Net weights (approx.): TX800 6.4 kg, TX1600 12 kg, TX3200 23 kg, TX5400 56 kg.

8. What is the rated forward travel (stroke) per pump/pull?

Rated forward travel per stroke (minimums) are approximately: TX800 ≥ 52 mm, TX1600 ≥ 55 mm, TX3200 ≥ 28 mm, TX5400 ≥ 25 mm.

9. What handle lengths are provided?

Handle length options noted in the data: L1 = 692 mm (common for several models), L2 = 1200 mm, and L3 = 800 mm. Some models may ship with a specified handle length—confirm with the seller.

10. Can this hoist be used for vertical lifting?

Tirfor-style hoists are often used for both pulling and controlled lifting, but vertical lifting requires correct rigging, rated components, and adherence to local safety standards. Verify the manufacturer’s instructions and local regulations before using for lifting personnel or critical vertical lifts.

11. How do I choose the correct model for my load?

Select a model with a rated load equal to or greater than the heaviest load you intend to lift or pull and include an appropriate safety margin. Also consider rope diameter, stroke/repeat travel needed, and the available anchoring points.

12. What routine maintenance is required?

Regularly inspect the wire rope for wear, kinks, corrosion and broken strands; check the body and pawls for damage; keep the mechanism clean and lightly lubricated as recommended by the manufacturer; replace worn or damaged ropes/parts immediately.

13. Are replacement ropes and spare parts available?

Replacement wire ropes and spare parts are typically available; order parts that match the model and specified rope diameter. Contact the supplier or manufacturer with your model number (TX800/TX1600/TX3200/TX5400) to get correct parts.

14. Does the product come with certification or warranty?

Certification and warranty vary by supplier and region. The technical sheet provides working values, but you should request safety certificates (e.g., load test certificates) and warranty details from the seller prior to purchase.

15. What safety precautions should I follow when using this hoist?

Never exceed rated load, use appropriate anchor points and slings, wear PPE, inspect rope and device before each use, keep bystanders clear, operate on stable footing, and follow the manufacturer’s instructions and applicable safety standards.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading