B21, China Town Mall, Midrand

16 Spindle Apparel Textile Machinery With High Speed Braiding Machine For Decoration Rope

- Section : Machinery

- Category : Textile Machinery

- SKU : 1600846094175

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 04 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

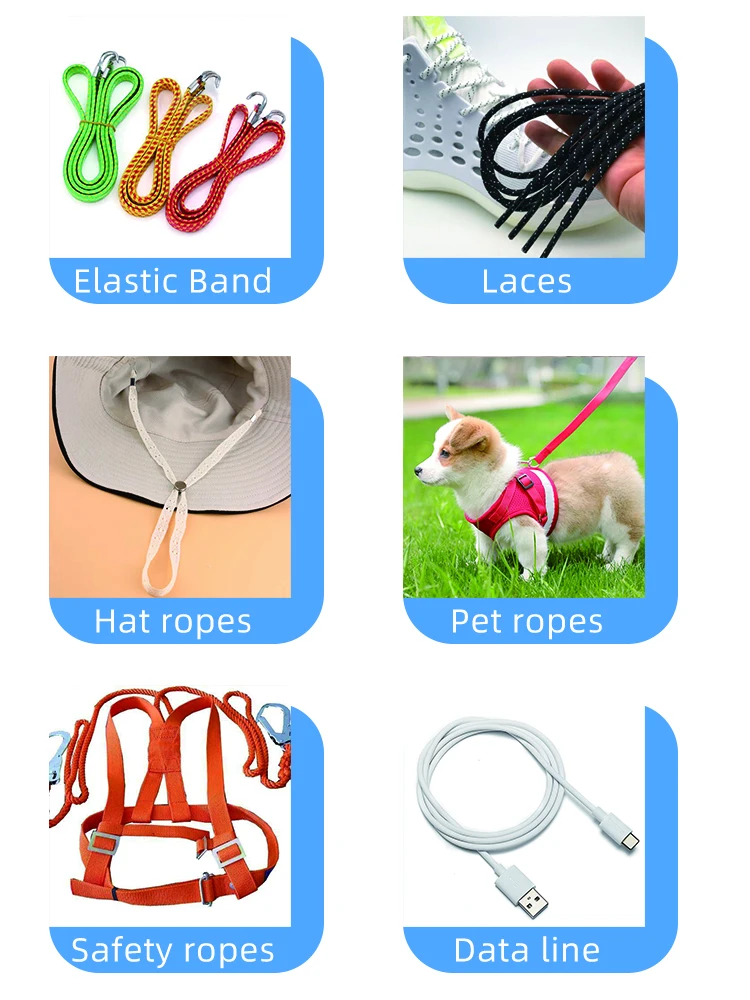

1. What is the Qixing 16-spindle braiding machine used for?

This machine is designed for high-speed braiding in textile and manufacturing applications, including decoration rope, general textile braids, technical braids and, when used with enclosed heads, precision medical products (e.g., heart-stent braiding).

2. What are the main technical specifications?

Key specs: weight ~800 kg; 4 heads; 16 spindles; impeller size 90 mm; maximum impeller speed 330 rpm; bobbin size options (see below); voltage options 110V/220V/380V/440V, single- or three-phase; PLC control and Holip inverter for speed control.

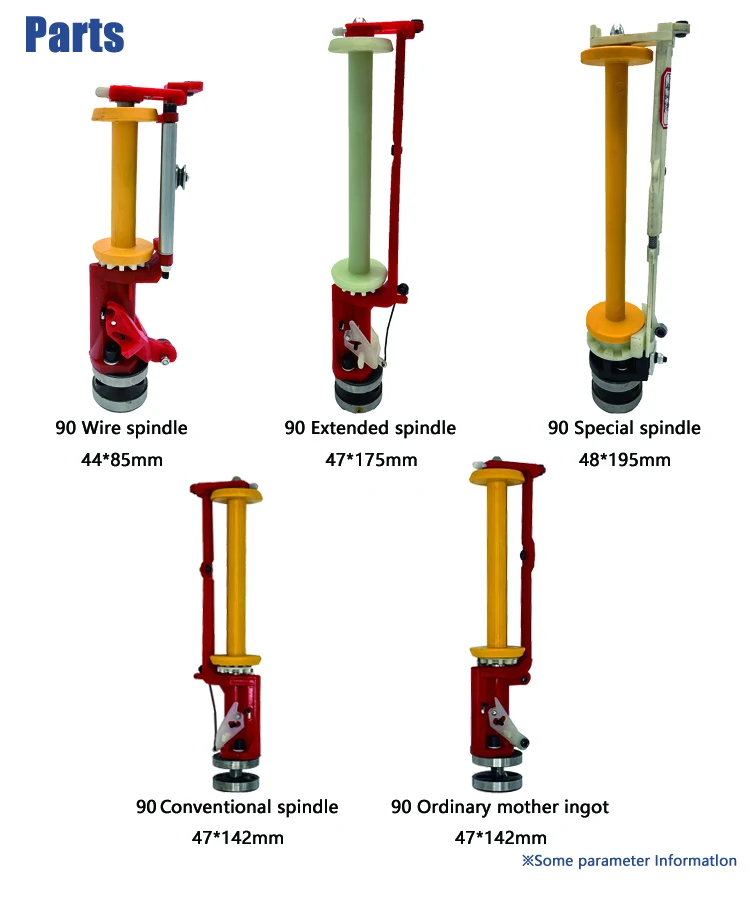

3. What bobbin sizes does the machine accept?

The machine supports multiple bobbin options. Standard offerings include bobbins with D:44 mm in lengths 85 mm, 140 mm, 175 mm and 195 mm. Larger/custom bobbins are also available (example listed: diameter 65 mm, height 200 mm). Contact the supplier to confirm the best bobbin for your application.

4. What electrical supply options are available?

Available voltage configurations include 110V, 220V, 380V and 440V, with single-phase or three-phase options. Units can be customized to your local electrical system—confirm when ordering.

5. What control and speed regulation does the machine have?

The machine uses PLC control and an inverter (Holip) for speed regulation. Control panel options include a button control panel or a touch-screen panel for easier operation and more complete functions.

6. How does the traction system work and what options exist?

Traction is provided by rollers; available styles include diagonal roller, flat roller, connection roller, rope wheel (groove wheel) and track. The appropriate traction roller is selected based on the product being braided—provide sample/product specs and technicians will advise.

7. Are there enclosures available for dust/noise reduction or precision work?

Yes. Semi-enclosed and fully enclosed configurations are available using materials like aluminium, organic glass and metal. Enclosures reduce dust and noise and enable production of precision items such as heart stents.

8. What warranty and quality inspections come with the machine?

The machine comes with a 1-year warranty. The supplier provides machinery test reports and outgoing inspection videos to verify quality before shipment.

9. What routine maintenance is required?

Routine maintenance includes regular lubrication of bearings and gears, inspection and replacement of compression springs and ratcheting parts as needed, checking spindle and bobbin condition, and ensuring the inverter/PLC connections are secure. Follow the manufacturer's maintenance schedule for intervals.

10. What spare parts or wear parts should I expect to keep on hand?

Common spare/wear parts include bearings, gears, compression springs, bobbins, traction rollers, drive belts and electronic components (PLC/inverter). The supplier can provide a recommended spare-parts list based on your usage.

11. How does the machine's configuration (heads/spindles/speed) affect production output?

Higher spindle count, more heads and faster impeller speed increase production capacity. This model's 4 heads and 16 spindles with a max impeller speed of 330 rpm provide high throughput, but exact output depends on braid pattern, yarn type, tension and operator settings.

12. What materials can be braided on this machine?

The machine is suitable for a wide range of yarns and filaments used in decoration ropes, textile braids and many technical textiles. For specialized materials (e.g., metals for medical stents, high-modulus fibers), consult the supplier to confirm compatibility and recommended tooling.

13. Is customization available (bobbin size, voltage, control features)?

Yes. The manufacturer offers customization for bobbin dimensions, voltage/phase, control-panel type and other components. Provide your product requirements and operating conditions to get a tailored configuration.

14. Does the supplier provide installation, commissioning and operator training?

The supplier offers pre-shipment testing, outgoing inspection videos and typically provides installation and commissioning support and operator training—confirm the level of on-site assistance and any associated fees when ordering.

15. What should I consider for shipping, lifting and site preparation?

The machine weighs about 800 kg, so plan for adequate lifting equipment, a stable foundation/floor and suitable electrical supply. The supplier can advise on packaging, crating for export and any special lifting points to ensure safe delivery and installation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading