B21, China Town Mall, Midrand

Yihui LCD 3D Printer For Jewelry, Dental, And Education Printing

- Section : Medical Supplies

- Category : Dental Consumables

- SKU : 62013062611

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the build volume (forming size) of the Yihui LCD 3D Printer?

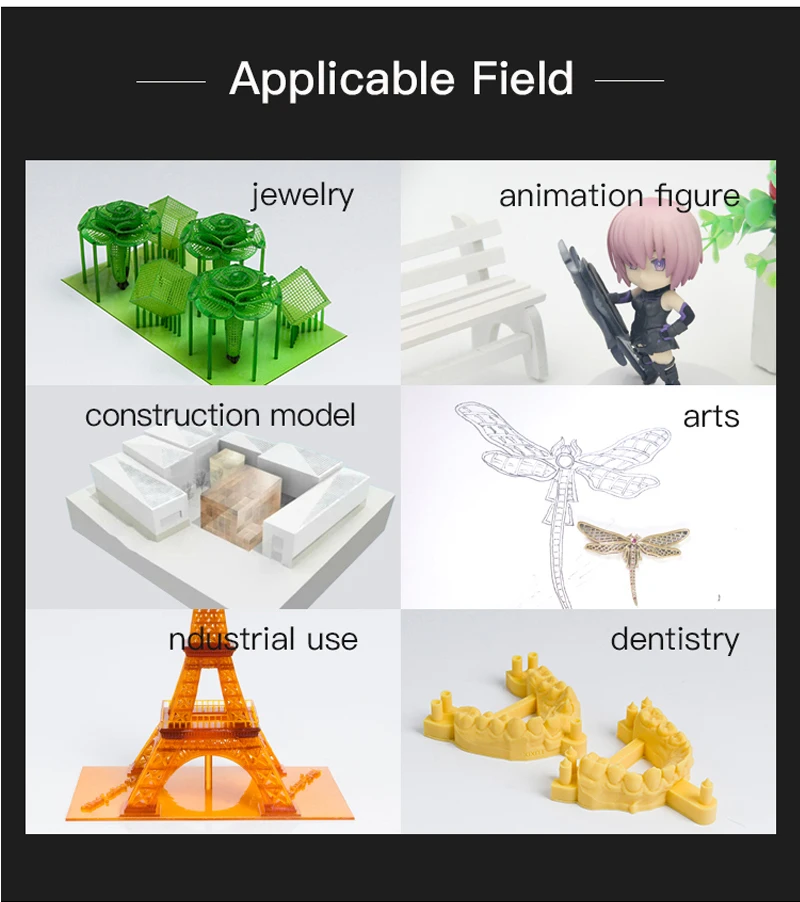

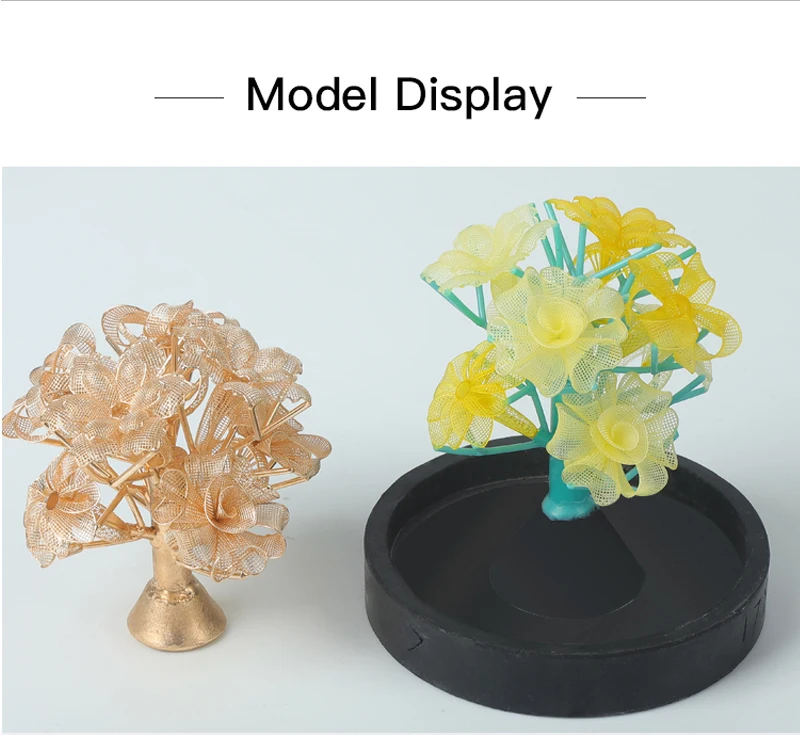

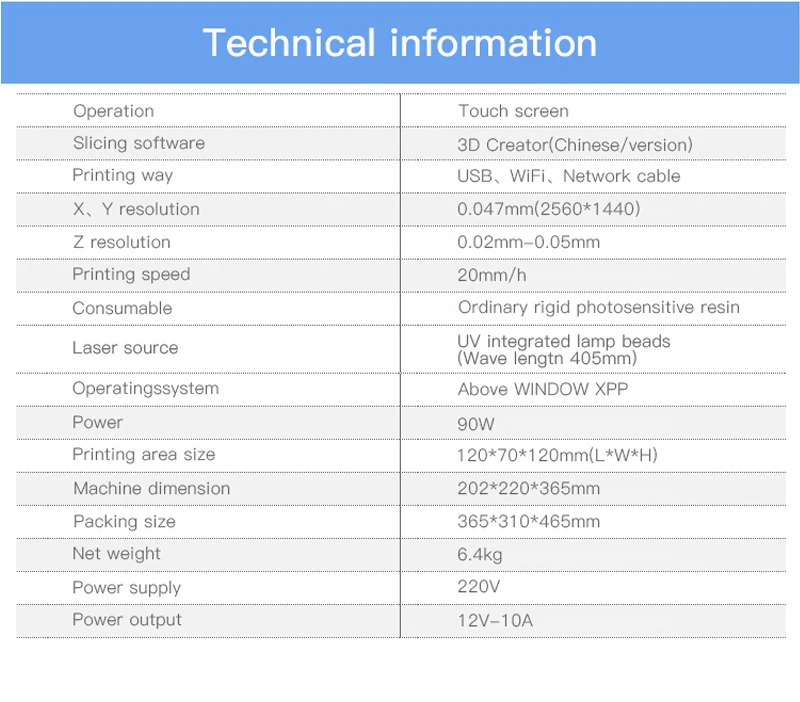

The build volume is 120 × 70 × 120 mm, suitable for small high-detail parts used in jewelry, dental models, watches and educational projects.

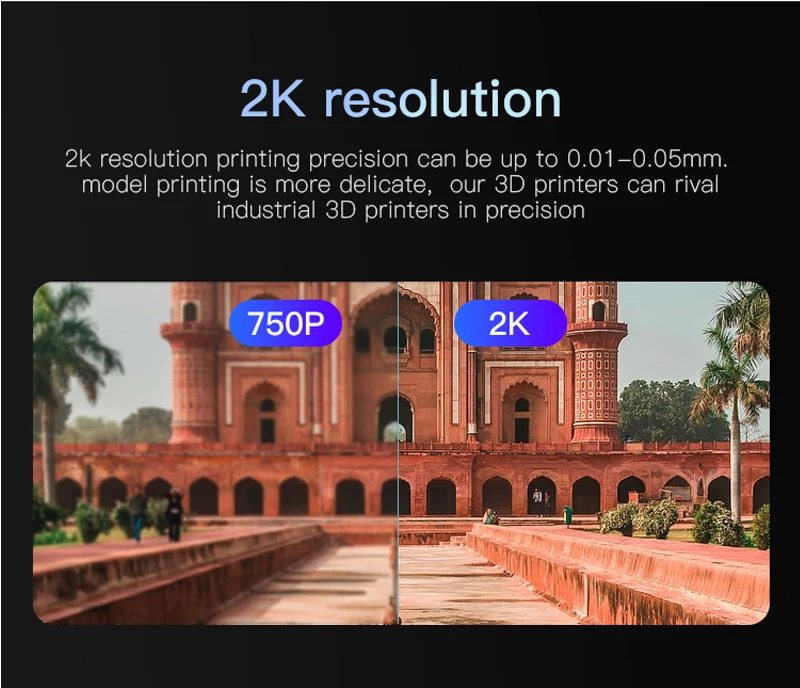

2. What resolution and printing accuracy does this printer offer?

The printer has an XY resolution of 0.047 mm (2560 × 1440 pixels), enabling high-detail prints. Layer thickness is adjustable and commonly ranges from around 10–100 microns depending on resin and settings.

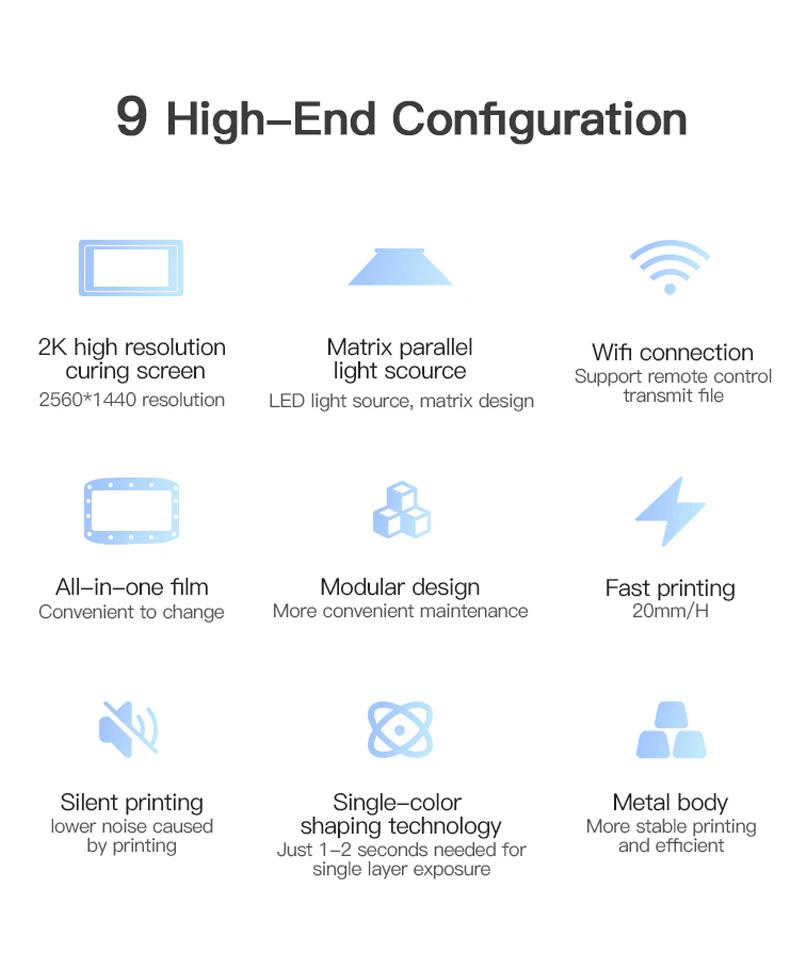

3. What printing speed can I expect?

Typical print speed is up to 20 mm/hour (Z axis), though effective speed depends on layer height, exposure settings and the resin used.

4. Which materials/resins are compatible with this LCD printer?

This UV LCD printer is compatible with standard photopolymer resins including castable resins for jewelry, dental model resins and general-purpose resins designed for 405 nm LCD systems. Always confirm resin compatibility and recommended exposure settings with the resin supplier.

5. Does the printer include a UV light source?

Yes. The printer uses an integrated UV LED lamp bead array as its light source for curing resin layers.

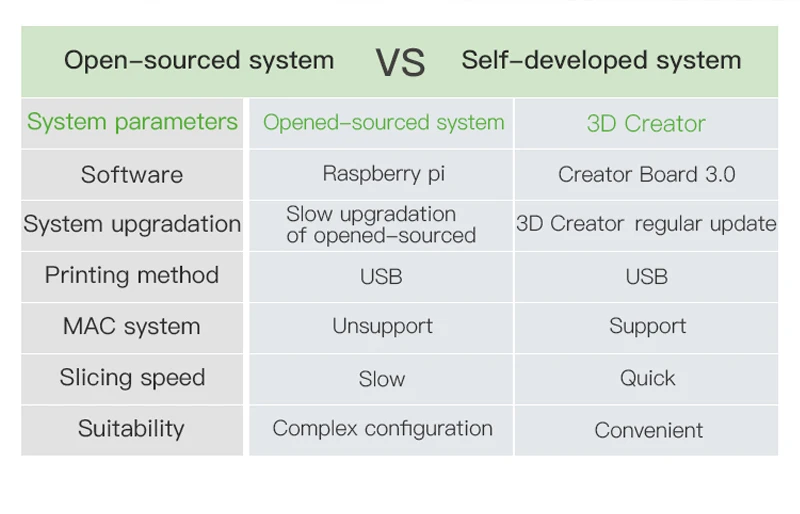

6. What software and file formats are supported?

The printer uses 3D Creator (Chinese/English) slicing software. Common input formats such as STL and OBJ are supported by most slicers and the included software; export sliced files for printing via USB, network or Wi‑Fi.

7. How can I connect to the printer and transfer print files?

You can send files via USB, Wi‑Fi or a network cable. The printer supports multiple connectivity options for convenience in workshops and classrooms.

8. What are the printer's physical dimensions and weight?

Machine footprint is approximately 202 × 220 × 365 mm. Net weight is listed at about 6.4 kg; packaged or shipping weight can be approximately 12 kg depending on accessories and packaging.

9. What power requirements does the printer have?

The printer requires 220 V power and consumes about 90 W. If you are in a region with 110 V mains, use a certified voltage converter/transformer or consult local support.

10. Is there a warranty and technical support available?

Yes. The product includes a 1‑year warranty. For technical support and service, contact the manufacturer or authorized reseller; the unit is manufactured in Guangdong, China.

11. Is this printer suitable for jewelry casting and dental workflows?

Yes. It is specifically designed for high‑detail jewelry and dental modeling. Use castable resins for investment casting workflows and approved dental resins for model and appliance production. Validate workflows and post‑processing steps to meet your lab’s requirements.

12. What post‑processing is required after printing?

Typical post‑processing includes rinsing printed parts in isopropyl alcohol or a dedicated wash solution to remove uncured resin, followed by post‑curing under a UV lamp to reach final mechanical properties. Castable and dental parts may require additional burnout or finishing steps per material guidelines.

13. What routine maintenance does the printer need?

Routine maintenance includes keeping the resin vat and FEP film clean, periodically replacing the FEP if damaged, cleaning the build platform, keeping the LCD and optics free of resin and dust, and following any lubrication/calibration steps in the user manual. Regular checks will prolong accuracy and component life.

14. Are there safety considerations I should follow?

Yes. Use gloves and eye protection when handling uncured resin, ensure adequate ventilation when printing and post‑processing, avoid direct eye exposure to UV light, and follow local disposal rules for uncured resin and contaminated solvent. Consult the resin and machine safety documentation for details.

15. How easy is setup and use for educational environments?

The Yihui printer features a 3.5" touch screen and simplified workflow via 3D Creator software, making it suitable for classrooms and labs. Its compact footprint and automatic features reduce setup complexity, but initial training on resin handling and post‑processing is recommended for safe operation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading