B21, China Town Mall, Midrand

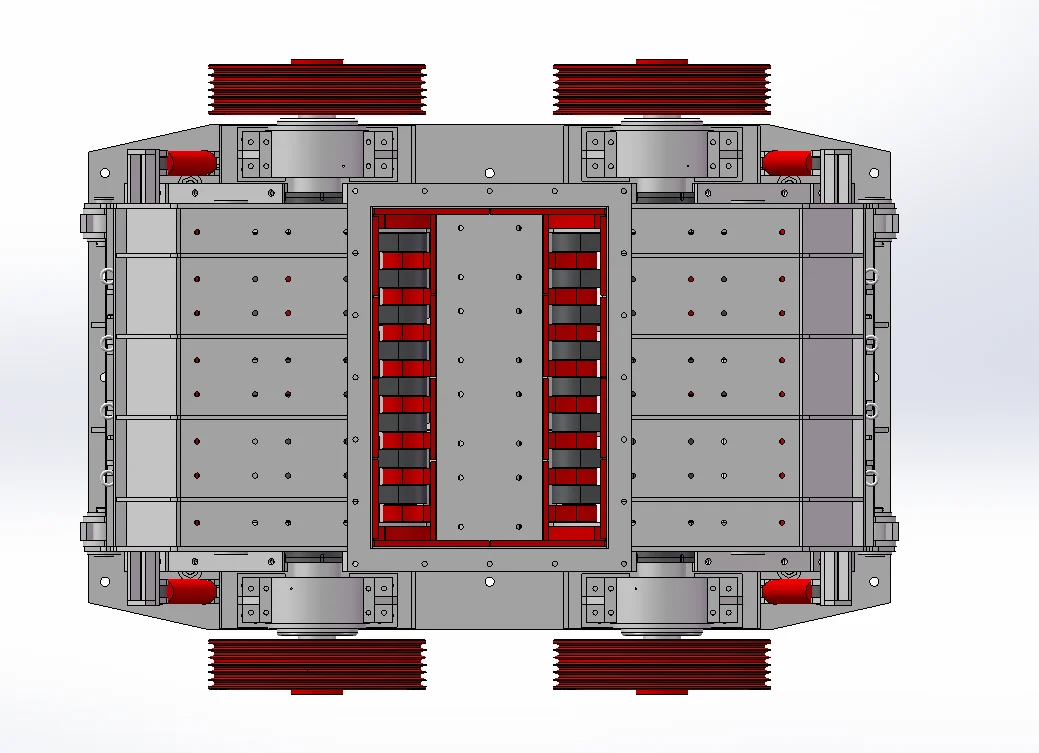

Stone Crusher Machine Double Rotor Sand Making Machine for Quarry Works

- Section : Machinery

- Category : Mining Machinery

- SKU : 1600856796035

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials can the Stone Crusher Machine Double Rotor Sand Making Machine process?

The machine can process various materials including limestone, bluestone, coal gangue, shale, and gravel.

2. What is the production capacity of the XGN-SZJ series machines?

The XGN-SZJ1315 model has a production capacity of 150-220 t/h, while the XGN-SZJ1516 model can produce between 220-300 t/h.

3. How does the double rotor design benefit the crushing process?

The double rotor design allows for simultaneous high-speed rotation of two sets of rotors, which enhances crushing efficiency and ensures finer material output.

4. Can the gap between the grate bar and hammer head be adjusted?

Yes, the gap can be adjusted flexibly, allowing for the production of aggregate and machine-made sand with varying fineness.

5. What are the overall dimensions of the XGN-SZJ1516 model?

The overall size of the XGN-SZJ1516 model is 4190*3220*2360 mm.

6. What is the power requirement for the machine?

The XGN-SZJ1315 model requires a motor power of 110 kW, while the XGN-SZJ1516 model requires 160 kW.

7. Is this machine suitable for use in a concrete mixing station?

Yes, this machine is suitable for various applications including sand and gravel quarries, mining, and concrete mixing stations.

8. What is the feeding port size of the XGN-SZJ1315 model?

The feeding port size of the XGN-SZJ1315 model is 1000 mm width by 1570 mm length.

9. What advantages does this machine offer compared to other sand making machines?

This machine integrates fine crushing and shaping, offers adjustable fineness modulus, and ensures reasonable gradation, effectively saving on equipment investment costs.

10. What is the principle of operation of the double rotor sand making machine?

The machine operates by crushing material with the upper rotor and then finely crushing it further with the rapidly rotating lower rotor, allowing for efficient material reduction.

11. Can this machine produce both fine aggregates and sand?

Yes, it can produce both fine aggregates and machine-made sand simultaneously.

12. What industries can benefit from using this machine?

Industries such as construction, mining, and material processing for concrete applications can benefit from using this machine.

13. What is the maximum feed size for the XGN-SZJ1516 model?

The maximum feed size for the XGN-SZJ1516 model is 280 mm.

14. How does the machine ensure the material is finely crushed?

The machine ensures fine crushing by using high-speed rotors that create rapid collisions among materials, leading to effective material breakdown.

15. Is the machine easy to maintain?

Yes, the design of the machine allows for easier maintenance, helping to reduce downtime and improve operational efficiency.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading