B21, China Town Mall, Midrand

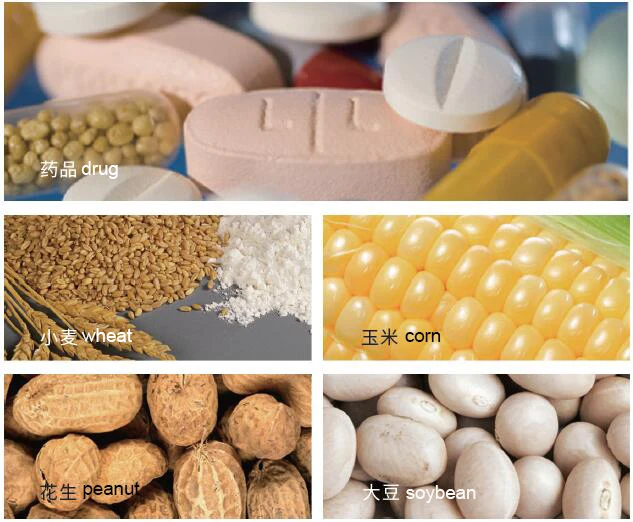

SOX406 Fat Analyzer Soxhlet Extractor for Foods, Feeds, Medicines

- Section : Medical Supplies

- Category : Testing Instrument

- SKU : 1585202077

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the SOX406 Fat Analyzer used for?

The SOX406 is a Soxhlet-style fat analyzer designed to determine fat (lipid) content in foods, animal feeds, medicines and other solid or semi-solid samples (also suitable for soils, polymers, textiles, etc.). It integrates soaking, extraction, heating, condensation and solvent recovery in one unit.

2. What is the sample size and throughput?

Sample weights between 0.5 g and 15 g can be analyzed (2–5 g is typical for accurate results). The unit processes up to 6 samples per batch.

3. What temperature range and accuracy does the SOX406 offer?

Temperature is adjustable from room temperature +5°C up to 280°C. Built-in PID control provides temperature accuracy of ±1°C.

4. What solvents can I use and what is the solvent cup volume?

Common Soxhlet solvents such as petroleum ether, hexane and ether may be used—choose solvent appropriate for your method and safety rules. Each solvent cup has an 80 mL volume. Always follow solvent compatibility and safety guidance.

5. How efficient is the solvent recovery?

The SOX406 has a high solvent recovery rate of ≥80%, which reduces solvent consumption and operating cost. Actual recovery depends on solvent type and operating conditions.

6. How long does extraction take and can it be shortened?

Extraction time depends on sample matrix, solvent and method parameters. The design can shorten extraction time by approximately 20%–80% compared with some conventional procedures, depending on conditions.

7. What safety and alarm features are included?

Safety features include complete isolation between electrical circuits and extraction space, air-insulation to keep the cabinet near room temperature, over-temperature alarm and timer reminders. The unit provides triple alarms (sound, light and LCD text) and has an all-around 360° safety design.

8. What display and control interface does the instrument have?

The SOX406 uses a 4.3-inch LCD with microcomputer control. The interface displays set temperature, actual temperature, set time and elapsed heating time simultaneously and supports intelligent man–machine dialogue control.

9. What are the performance specs (measurement range, reproducibility, power)?

Measurement range is 0–100% fat. Reproducibility relative error is approximately 1%. Rated power consumption is 1 kW and the unit requires 220 VAC ±10%, 50 Hz.

10. What routine maintenance and cleaning are required?

Regularly clean extraction glassware (thimbles, condensers, solvent cups), check and replace seals/gaskets if worn, inspect electrical connections and the heating bath for corrosion, and ensure vents are clear. Follow solvent-specific cleaning procedures and drain/dispose solvent residues per local regulations.

11. How do I validate or calibrate the SOX406 for accurate results?

Validate using certified reference materials or standard test samples and follow your laboratory's method validation procedures (precision, accuracy, recovery). Periodically verify temperature accuracy and timing and run control samples to monitor performance.

12. Is the SOX406 compliant with standard Soxhlet methods (e.g., AOAC/ISO)?

The SOX406 is based on the Soxhlet extraction principle and can be used to perform Soxhlet-based methods. To ensure compliance, set method parameters (sample weight, solvent, extraction time, temperature) according to the specific AOAC/ISO standard you follow.

13. What consumables and spare parts should I keep on hand?

Keep spare solvent cups (80 mL), extraction thimbles, seals/gaskets, condensers, tubing, and common replacement fuses or sensors. Maintain appropriate quantities of your chosen solvent and personal protective equipment.

14. How should I handle solvent and waste from the extraction?

Collect and store used solvents in appropriate, labeled containers and dispose of or recycle them according to local hazardous-waste regulations. Use proper ventilation, grounding and explosion-proof equipment when handling flammable solvents.

15. What is the difference between the SOX406 and the related SOX606 model?

SOX606 is listed as a related model; differences typically include capacity, feature set or performance improvements. For exact comparisons (batch size, power, dimensions, advanced features), refer to the technical datasheets for each model or consult the manufacturer/supplier.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading