B21, China Town Mall, Midrand

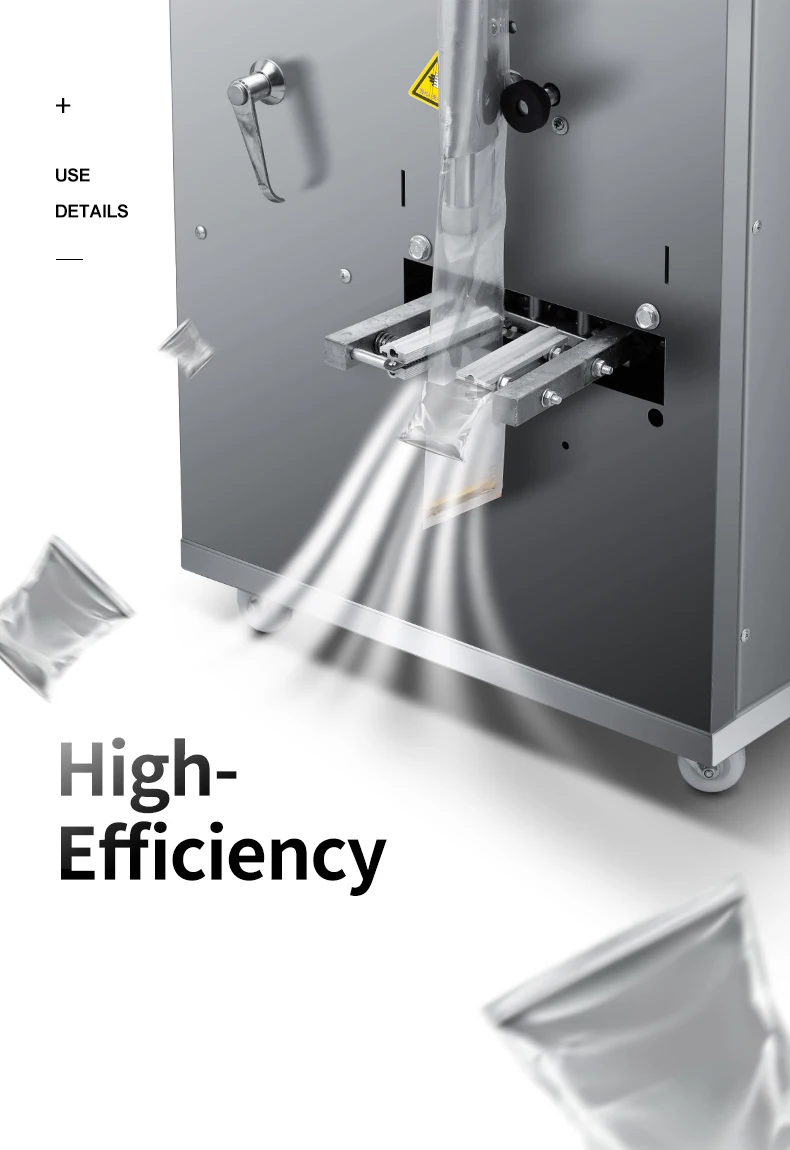

Soft drink automatic liquid sachet filling machine

- Section : Machinery

- Category : Wrapping Machines

- SKU : 1600466252692

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Soft drink automatic liquid sachet filling machine?

A fully automatic, food-grade stainless steel machine designed to form, fill and seal single-portion sachets/pouches for soft drinks and other free-flowing liquids. It provides intelligent control, stable performance, and energy-saving operation for food and pharmaceutical packaging.

2. Which models are available and how do they differ?

Available models: OX-LGYDS60, OX-LGYDS70, OX-LGYDS80, OX-LGYDB61, OX-LGYDB71, OX-LGYDB81, OX-LGYDB91. Main differences are filling range and packing speed: ranges cover 10–100 ml, 30–300 ml, 50–500 ml and 100–1000 ml; packing speeds vary by model from about 3 to 15 pcs/min. All models use 220V/50Hz power and share ±1% filling precision.

3. What filling accuracy can I expect?

Filling precision is ≤ ±1% under normal operating conditions. Actual accuracy depends on liquid properties, selected pump/nozzle, calibration and correct machine setup.

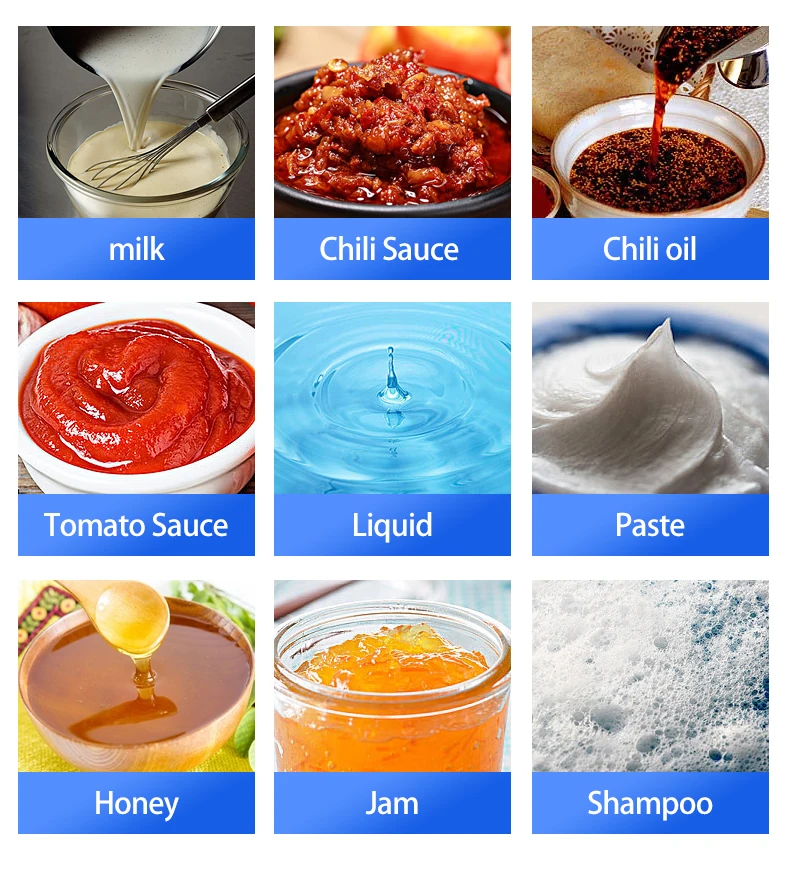

4. What liquid products can this machine handle?

It handles water-like and low-to-medium viscosity liquids such as soft drinks, juices (without large solids), clear syrups and liquid pharmaceuticals. It is not suitable for high-viscosity fluids or liquids containing particulates unless specially modified.

5. What are the packing speeds in practical terms?

Packing speeds vary by model and pouch size: top speeds are up to 15 pcs/min (≈900 pcs/hour) on higher-speed models; lower-capacity models run from about 3–10 pcs/min (≈180–600 pcs/hour). Actual throughput depends on fill volume, pouch size, and operator efficiency.

6. What packaging materials and pouch types are supported?

Compatible with roll materials that are heat-sealable: plastic film, laminated composite film and aluminum foil based heat-seal composites. Typical output is sachets/pouches formed from roll stock (pillow/flat sachets). Specific pouch shapes and sizes depend on the forming tools—confirm for special pouch types.

7. What are the machine dimensions and footprint?

Dimensions vary by model. The specification sheet lists model-specific sizes; for exact footprint and layout (including service clearances) request the dimensional drawing from the supplier or sales engineer.

8. What utilities are required (power, air, etc.)?

Standard electrical supply: 220V/50Hz for all listed models. Some configurations may require compressed air or other utilities for pneumatic components—please check the detailed spec sheet or consult the supplier for exact air pressure/flow requirements.

9. How easy is cleaning and maintenance?

Machine contact parts are food-grade stainless steel and designed for easy disassembly. Routine cleaning and maintenance are straightforward; follow the supplier's cleaning instructions. For CIP or specific sanitation requirements, discuss options with the manufacturer.

10. How long does changeover take between different fill volumes or pouch sizes?

Changeover time depends on the model and extent of the change (minor adjustments vs. swapping forming tools). Many adjustments are made via the control panel; mechanical part changes may be needed for different pouch sizes. The supplier can provide typical changeover times and training.

11. Is the machine suitable for sterile or pharmaceutical production?

The machine is built from food-grade stainless steel and can be used in pharmaceutical contexts for non-sterile liquid filling. For sterile or GMP-grade pharmaceutical production, additional design, validation, and qualification may be required—discuss regulatory requirements with the manufacturer.

12. What spare parts and support are available?

Spare parts, wear parts (nozzles, seals, cutters, belts) and after-sales support are typically available through the supplier. Availability, lead times and warranty terms vary—confirm spare parts kits and support packages when purchasing.

13. Does the machine come with warranty, installation and operator training?

Warranty, installation, commissioning and operator training are commonly offered but depend on the seller. Confirm the exact warranty period, what is covered, and whether on-site installation and training are included or offered as add-ons.

14. Can this machine be customized (multi-lane, different volumes, more speed)?

Yes—many manufacturers offer customization such as different filling pumps/nozzles for various volumes, alternate forming sets for special pouch sizes, multi-lane configurations or higher-speed options. Contact the supplier with your product details and output requirements for a tailored solution.

15. How can I get samples or test my product on the machine before buying?

Most suppliers offer sample testing—either at their factory, a demonstration facility or by arranging trial runs. Provide product samples, desired pouch size and target speed so they can validate filling accuracy and suitability before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading