B21, China Town Mall, Midrand

Smoother Running Rational Structure Packaging And Sealing Machine Butter Packaging Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1601011913971

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What products can this packaging machine handle?

The machine is multi-functional and handles foods, beverages, commodities, chemicals, and machinery & hardware. It supports bag and pouch packaging and can be adjusted for different container sizes and product types.

2. What is the packing speed and production capacity?

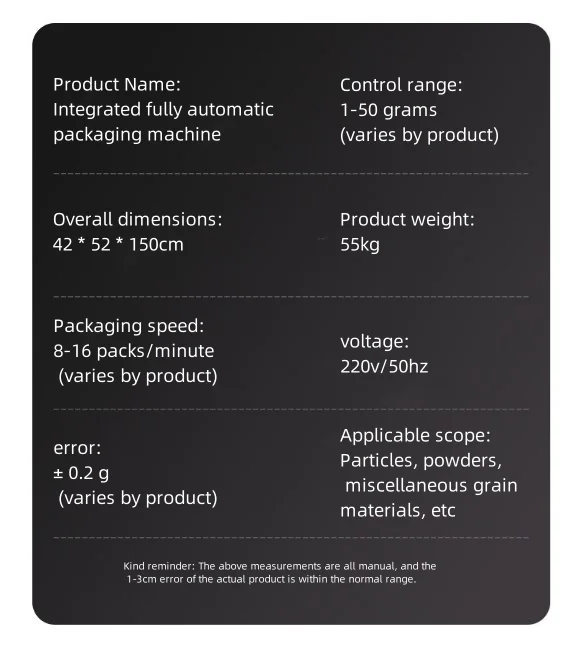

Packing speed ranges from about 7–16 bags per minute depending on the product and film used. Production capacity options listed include models rated at 8, 10 or 15 bags/min; actual throughput depends on material, bag size and operator settings.

3. What level of weighing accuracy can I expect?

Typical accuracy is ±2 g, but final accuracy depends on the product characteristics (bulk density, flowability) and calibration. For best results, test with your product before full production.

4. What power supply does the machine require?

The machine supports 220 V or 110 V at 50/60 Hz. For specific power consumption values and any special electrical requirements, contact the supplier or check the machine nameplate.

5. What materials and films are compatible with the sealing system?

The machine is designed for heat-sealable films and common packaging materials. In practice it works with PE/PP/OPP/CPP and many laminated films where heat sealing is appropriate. Film compatibility will depend on thickness and sealing temperature; validate with samples.

6. How easy is it to change molds or format parts?

The machine features an advanced quick mold replacement system that allows tool-free mold changes in just a few minutes, which reduces downtime for format changes.

7. What safety features are included?

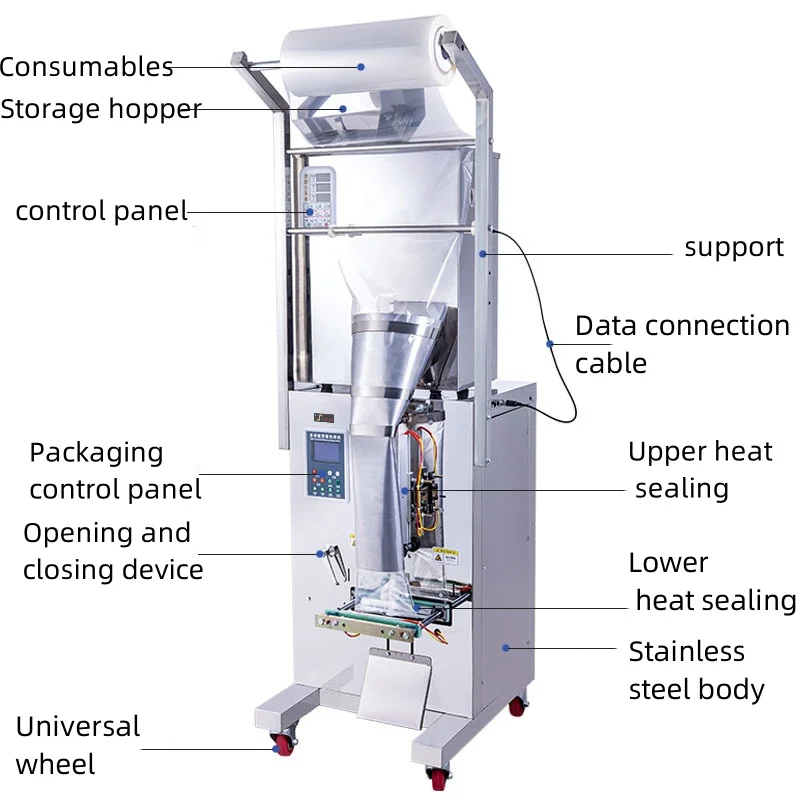

A stainless steel protective cover is provided to safeguard operators from moving parts. The machine design also emphasizes stable voltage behavior and heat management to reduce risk during extended runs. Follow the provided safety instructions for safe operation.

8. What maintenance is required and how often?

Routine maintenance includes cleaning sealing jaws and film paths, inspecting and lubricating moving parts as recommended in the manual, checking springs and the high-temperature glue component, and replacing wear parts as needed. Frequency depends on usage; daily cleaning and weekly inspections are common.

9. Is the machine suitable for continuous high-speed operation?

Yes — the machine is designed for stable operation with features like heat-resistance design, voltage stability, and crack-resistant structure to support long runs. However, performance will depend on correct setup, cooling intervals for certain materials, and adherence to maintenance schedules.

10. What warranty and after-sales support are provided?

The product specification includes a 1-year warranty. The supplier provides a machinery test report and outgoing inspection video. For installation, spare parts and long-term support, contact the seller to discuss available service packages.

11. Can the machine be integrated into an existing production line?

Yes — the machine is designed for seamless integration. Communication interfaces and mechanical infeed/outfeed can be adapted, but final integration details (conveyors, sensors, PLCs) should be discussed with the supplier to ensure compatibility.

12. How does the machine handle voltage fluctuations?

The machine is built to remain unaffected by high or low voltage conditions, improving weighing accuracy and operational stability. For extreme fluctuations, we still recommend a stable supply or dedicated voltage stabilizer as a precaution.

13. What inspection or certification documentation is provided?

The supplier provides a machinery test report and a video of outgoing inspection. For specific certifications (CE, UL, food-safety certifications), request documentation from the supplier as these vary by model and destination market.

14. How do I clean the machine for food-grade applications?

Turn off and isolate power before cleaning. Use food-safe cleaning agents compatible with stainless steel and follow the manufacturer’s cleaning procedure. Remove film residues from sealing areas, rinse and dry parts thoroughly, and perform sanitization if required by your food safety protocols.

15. How can I order spare parts or request customization?

Contact the supplier or your sales representative with the machine model and part numbers or the required customization details. The supplier can quote spare parts, customized molds, and software/integration options and advise on lead times and pricing.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals