B21, China Town Mall, Midrand

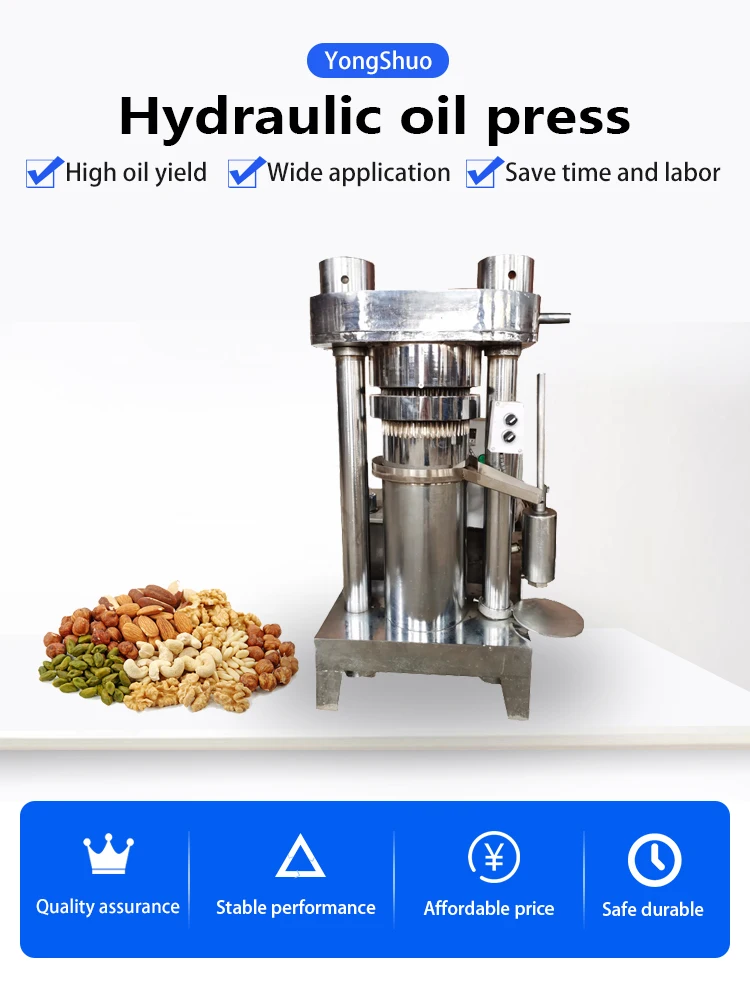

sesame pepper corn germ sacha inchi nut walnut olive macadamia nut almond avocado coconut cocoa oil hydraulic oil press machine

- Section : Machinery

- Category : Agriculture Machinery

- SKU : 1600754597052

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of seeds and nuts can this hydraulic oil press process?

The machine is multi-purpose and can process more than 20 oilseeds and nuts, including sesame, peanut, rapeseed, soybean, sunflower, flax, corn germ, sacha inchi, walnut, olive, macadamia, almond, avocado, coconut (copra), cocoa, and others.

2. How does the hydraulic oil press work?

The press uses a piston and hydraulic cylinder to apply steady high pressure to oil-bearing material in the barrel. An electric heating ring and automatic temperature controller help preheat and maintain optimal pressing temperature, improving oil yield and quality.

3. What are the main advantages of this hydraulic oil press?

Advantages include advanced design, reliable performance, simple operation, convenient maintenance, high oil yield, low power consumption, and the ability to produce pure oil from a wide range of seeds and nuts.

4. What is the typical oil yield and oil quality?

Oil yield and quality depend on the seed type, pretreatment (cleaning, drying, crushing), moisture content, and operating parameters. The hydraulic design and controlled heating promote higher yields and purer oil compared with many mechanical methods, but exact yields are model- and material-dependent.

5. What preparation do raw seeds/nuts need before pressing?

Prepare raw material by cleaning to remove stones and debris, drying to proper moisture content, and, where applicable, dehulling or crushing/grinding to increase surface area. Some seeds benefit from light roasting or conditioning prior to pressing—follow material-specific guidelines.

6. What are the main components and materials of the machine?

Key parts include the piston, hydraulic cylinder, column, movable upper beam, base, oil pump, barrel, electric heating ring, and automatic temperature control. Components are made from high-quality metal materials; food-grade stainless steel is typically available on request.

7. How is temperature controlled during pressing?

The machine is equipped with an electric heating ring and an automatic temperature control device so you can set and maintain the optimal pressing temperature for different oilseeds, improving extraction efficiency and oil quality.

8. What are the power and utility requirements?

Power consumption is relatively low compared with some alternatives, but exact electricity requirements depend on the model and heater size. Please provide your required capacity and local electrical specifications so we can recommend the correct model.

9. How easy is the machine to operate and maintain?

The press is designed for simple operation and convenient maintenance. Routine tasks include cleaning the barrel and pressing surfaces, checking hydraulic oil levels and seals, inspecting the heater and electrical connections, and scheduled lubrication. Detailed maintenance instructions are provided with the machine.

10. Is the oil produced ready for consumption after pressing?

The press produces crude oil that is typically clean and pure, but most producers filter and, if needed, refine (degumming, neutralization, bleaching, deodorization) to meet specific food standards. For cold-pressed or minimally processed oils, simple filtration and settling may be sufficient.

11. What safety features are included?

Safety features commonly include stable base and frame construction, pressure relief or safety valves in the hydraulic system, emergency stop, and electrical protections. Specific safety options can vary by model—ask for the safety specification sheet.

12. Can this machine be customized or supplied in different capacities?

Yes. Machines are offered in various models/capacities to suit small-scale to industrial needs, and customization (materials, power, control options) is typically available. Contact the supplier with desired throughput and application for recommendations.

13. What spare parts, warranty, and after-sales service are available?

Suppliers usually provide a warranty and stock common spare parts (seals, pistons, heating elements, sensors). After-sales support commonly includes installation guidance, operation training, and technical service. Confirm warranty length and spare-parts availability with the seller.

14. How do I clean the machine after production of sticky or high-oil materials?

After stopping and cooling, remove residual cake from the barrel and piston, wipe surfaces with food-safe cleaners or solvents as recommended, and flush the barrel if applicable. Follow the manufacturer’s cleaning procedure to avoid damaging seals or heating elements.

15. How do I choose the right model for my needs?

Decide based on target daily throughput, types of seeds/nuts you’ll process, available floor space, and local power supply. Provide these details to the supplier for a model recommendation and performance estimates (yield, cycle time). Sample testing is often available to verify yield for your specific raw material.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading