B21, China Town Mall, Midrand

Semi-Hard Cheese Production Line

- Section : Machinery

- Category : Other Food Processing Machinery

- SKU : 60498188510

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

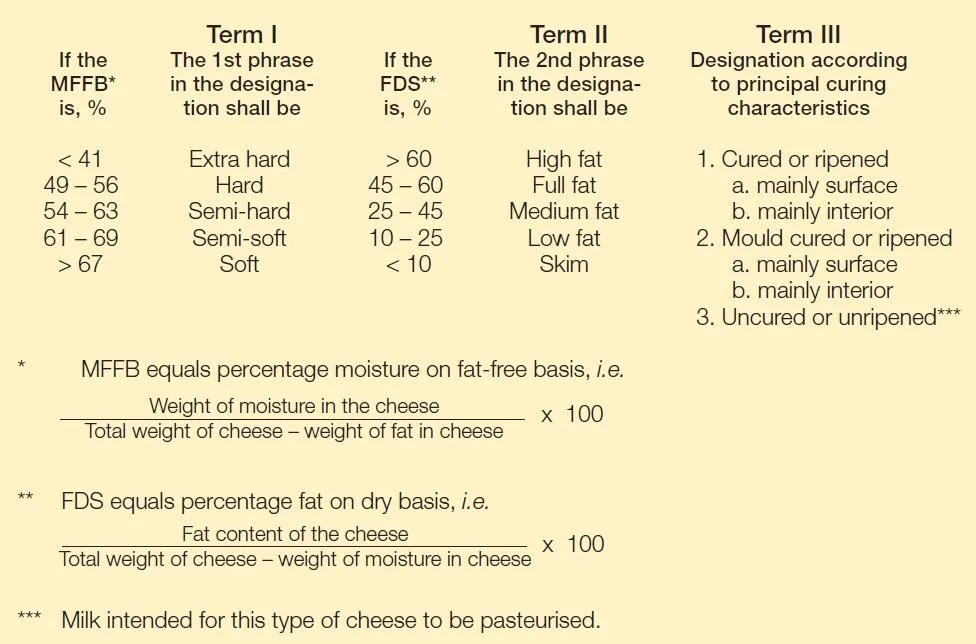

1. What types of cheese can be produced with the Semi-Hard Cheese Production Line?

The Semi-Hard Cheese Production Line is designed for various types of cheese, including soft, hard, and semi-hard varieties. Adjustments can be made during the curd treatment and pressing phases to suit specific cheese types.

2. What is the main process involved in cheese production with this equipment?

The main process includes pre-treatment and ripening, curd formation, fermentation, shaping, brining, and packaging. Each step is crucial for ensuring high-quality cheese with the desired texture and flavor.

3. How does the pre-treatment phase work?

During the pre-treatment phase, milk is treated and can be pre-ripened with a bacteria culture that is suitable for the cheese type. This step is essential for developing the cheese's flavor profile.

4. What role does rennet play in cheese production?

Rennet is added to coagulate the milk, transforming it into a solid gel called coagulum. This is a key step in the cheese-making process.

5. How is the curd formed and shaped?

The coagulum is cut into small cubes using special cutting tools to promote whey expulsion. The size of these cubes is adjusted based on the desired cheese texture. After cutting, the curd is placed in molds to define the cheese's shape.

6. What is the significance of bacterial growth in cheese production?

Bacterial growth is essential as it produces lactic acid from the milk's lactose, enhancing the cheese's flavor. This process occurs during the fermentation phase.

7. What is syneresis and how is it achieved?

Syneresis is the expulsion of whey from the curd. It is promoted through mechanical stirring and the application of heat during the cheese production process.

8. What happens during the brining process?

During brining, the cheese is soaked in a salt solution, which adds flavor and preserves the product. This step is critical for the final taste and shelf life of the cheese.

9. How is the final cheese packaged?

The finished cheese is coated, wrapped, or packed for distribution, ensuring it is protected and maintained for optimal freshness.

10. What features make this production line efficient?

The Semi-Hard Cheese Production Line is designed for efficiency through well-structured processes, automation options, and precise control over each step, which enhances productivity and consistency.

11. Is the equipment easy to operate?

Yes, the Semi-Hard Cheese Production Line is designed for ease of operation, often featuring user-friendly controls and automated processes that simplify the cheese production workflow.

12. What is the typical production capacity of this line?

The production capacity can vary based on the specific configuration and setup of the equipment. It is advisable to consult the manufacturer's specifications for detailed capacity information.

13. Can the production line be customized for different cheese types?

Yes, the Semi-Hard Cheese Production Line can be customized to accommodate various cheese types by adjusting the curd treatment and pressing phases according to specific requirements.

14. What maintenance is required for the production line?

Regular maintenance includes cleaning, checking mechanical components, and ensuring that all systems are functioning correctly. Following the manufacturer's guidelines is essential for optimal performance.

15. What safety features are included in the production line?

Safety features typically include emergency stop buttons, safety guards, and compliance with industry standards to ensure the safety of operators and the integrity of the production process.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading