B21, China Town Mall, Midrand

Sea salt production refinery sieving process vibrating screen machines

- Section : Machinery

- Category : Construction Machinery

- SKU : 60749675344

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Sea Salt Production Refinery Sieving Process Vibrating Screen Machine used for?

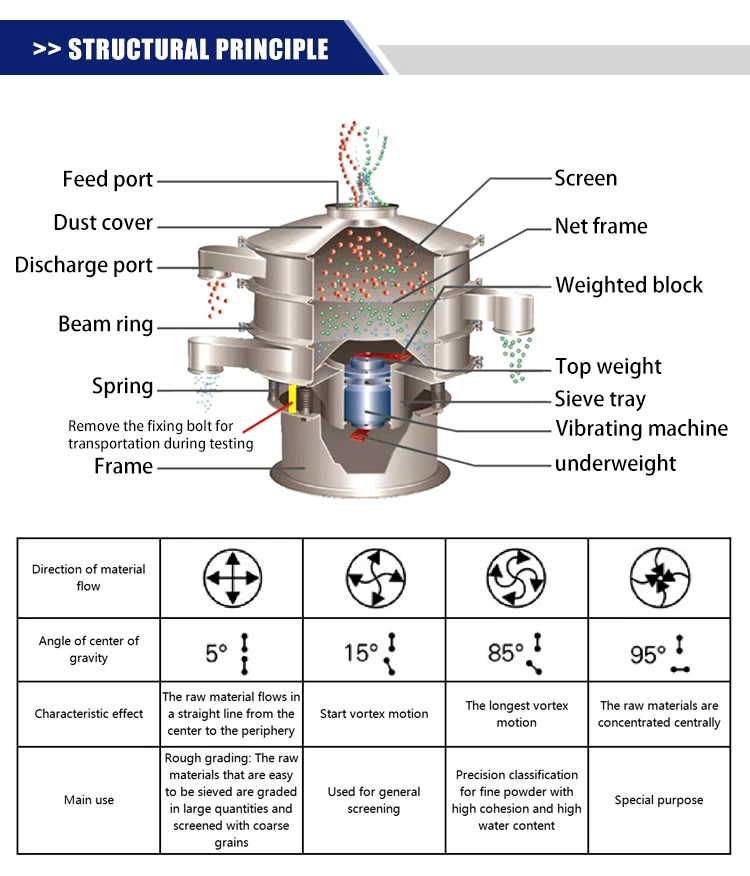

It is a rotary vibrating screen designed to screen, separate, sort and sieve powders and granular materials in food processing — including sea salt, grains, flour and similar materials — for grading and removing oversized particles or foreign matter.

2. What construction materials are available and which is best for food applications?

The machine is available in carbon steel or stainless steel. For food-grade use and better corrosion resistance (especially with salt), 304 or 316 stainless steel is recommended.

3. What capacities and throughput can this machine handle?

Capacity ranges from about 10 kg/hour up to 10 tons/hour depending on model, diameter, mesh size and material characteristics. Final capacity depends on particle size, bulk density and required cut size.

4. What sizes and configurations are available?

Diameters are available from 400 mm to 2000 mm, with customizable overall dimensions (L×W×H). Screening layers can be configured from 1 to 5 decks to meet different separation requirements.

5. What frequency and motor options are offered?

The machine operates with motors compatible with 50 Hz or 60 Hz supply. The motor provides a vertical excitation source with eccentric weights to generate horizontal, vertical and inclined motion; power rating and rotation speed should be specified at order to match local supply and application.

6. How does the cleaning system work and what are the options?

There are two cleaning options: mechanical bouncing balls (placed under the screen to dislodge blinding particles) and an ultrasonic cleaning system that transmits high-frequency vibrations to keep mesh clear. Bouncing balls are simple and cost-effective; ultrasonic is better for very fine or sticky materials.

7. How long does it take to change screens or perform a mesh changeover?

The rotary vibrating screen features a quick-change design — typical screen changeover takes about 3–5 minutes, depending on operator experience and configuration.

8. Is the machine certified and what warranty is provided?

The machine is CE certified and the manufacturer holds ISO9001:2008 certification. A 1-year warranty is provided for the unit under normal operating conditions.

9. Is this machine suitable for handling sea salt and other corrosive materials?

Yes — when specified in stainless steel (preferably 316 for higher chloride environments) the machine is suitable for sea salt and other corrosive products. Carbon steel models are less resistant to corrosion.

10. What maintenance is required to keep the sieving machine in good condition?

Regular maintenance includes inspecting and replacing worn screen cloths, checking and tightening fasteners, lubricating bearings per schedule, verifying motor and eccentric weights, and cleaning the unit after production. Follow the manufacturer's maintenance manual for specific intervals.

11. How do I choose the right mesh size and number of layers for my product?

Selection depends on target particle size, allowable oversize, throughput and material properties (moisture, abrasiveness). Finer cut sizes require finer mesh and may reduce throughput; multiple layers can separate several size fractions. Provide sample material and target specs to the supplier for an optimized recommendation.

12. What are the installation requirements and does the machine need anchoring?

The machine requires a level, rigid floor and appropriate electrical supply (50/60 Hz). Lighter models (~100 kg) may not need heavy anchoring but should be placed on a stable base and may be bolted or mounted to a frame depending on vibration isolation and plant layout. Consult installation instructions for anchoring and isolation pad recommendations.

13. What about noise and vibration — is it suitable for indoor food facilities?

The rotary vibrating screen is designed for low noise operation and an enclosed structure reduces dust. Proper installation with isolation mounts further minimizes transmitted vibration, making it appropriate for indoor food processing areas when installed per guidelines.

14. Can the machine integrate with existing production lines and automated systems?

Yes — customizable dimensions, inlet/outlet orientations and mounting options allow integration into conveyors, feeders and downstream equipment. Controls can be adapted to PLCs or factory automation systems on request.

15. How do I get a quote, lead time and spare parts support?

Contact the supplier with your material details, desired capacity, mesh size, preferred construction material and any dimensional constraints. Lead time depends on customization but typically ranges from a few weeks to a couple of months. Spare parts and service plans are available — ask the supplier to include recommended spare screens, bearings and cleaning system components in the quote.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading