B21, China Town Mall, Midrand

ROADWAY Concrete Milling Machine

- Section : Machinery

- Category : Engineering & Construction Machinery

- SKU : 1600549258414-1713166157

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

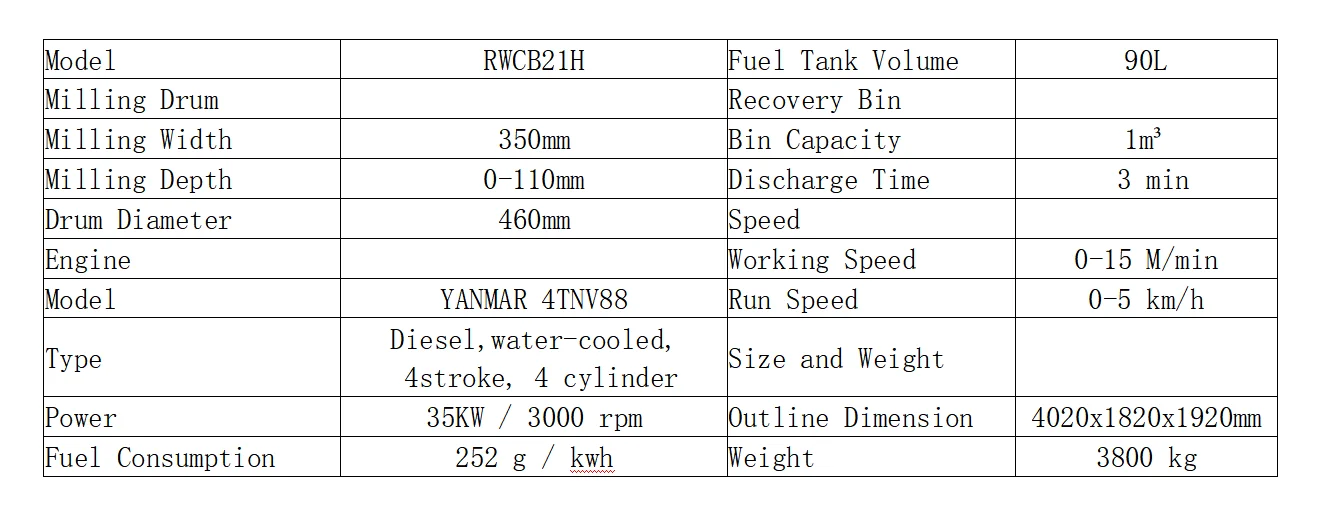

1. What is the engine model and power of the ROADWAY Concrete Milling Machine?

The machine is powered by a YANMAR 4TNV88 engine delivering 35 kW at 3000 rpm.

2. What hydraulic system does the machine use?

It uses an imported hydraulic system designed to provide reliable, smooth and precise milling operations.

3. What is the milling width and maximum milling depth?

The milling width is 350 mm and the adjustable milling depth ranges from 0 to 110 mm.

4. What is the working speed of the machine?

The working speed is variable from 0 up to 25 meters per minute, allowing control of milling progress.

5. How much debris can the machine collect?

The machine has a 1 m³ bin capacity to collect and hold milled material for efficient disposal.

6. How heavy is the ROADWAY Concrete Milling Machine and is it suitable for small jobs?

The machine weighs 3800 kg—compact enough for many resurfacing tasks while still providing robust milling capability for both small and larger jobs.

7. What surfaces and applications is this milling machine intended for?

It is designed for concrete and asphalt milling, surface leveling, removal of damaged layers, road repair, resurfacing preparation, and general construction site surface restoration.

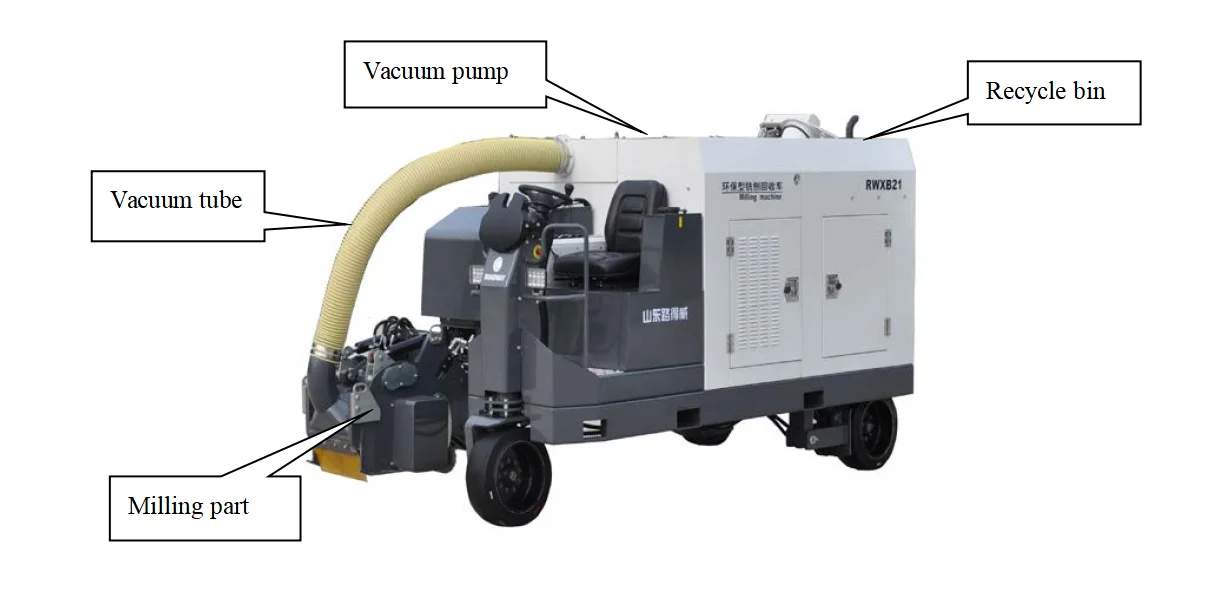

8. Does the machine provide dust control or environmental protection features?

The design emphasizes clean construction and environmental protection; it supports dust-reduction and material recovery workflows. For job-specific dust suppression or extraction options, consult the supplier or available accessory packages.

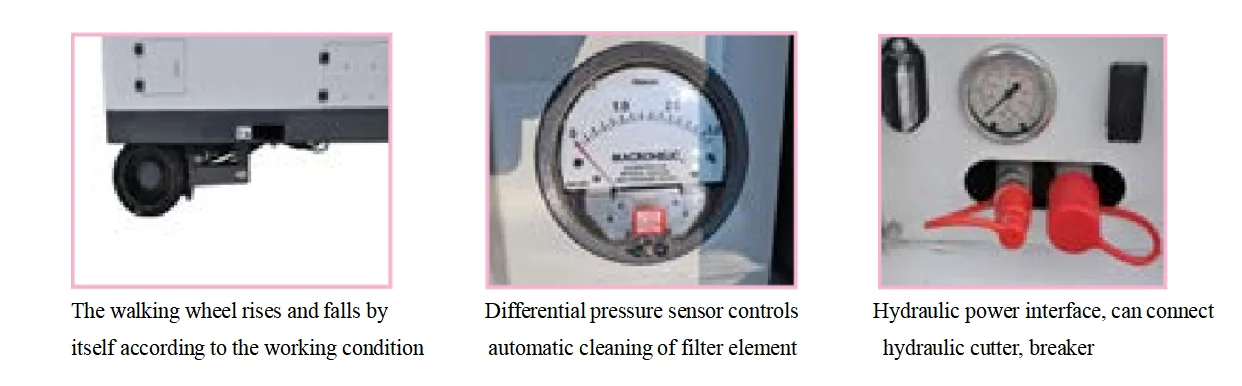

9. What type of tyres does the machine have and how do they affect performance?

The machine is fitted with antiskid tyres to improve stability and traction, reducing slippage on smooth or uneven surfaces during operation.

10. What routine maintenance is required to keep the machine running reliably?

Perform daily checks of engine oil, coolant, hydraulic fluid levels, and tyre condition. Inspect milling drum and tooling for wear, keep the debris bin and hydraulic connections clean, and follow the engine and hydraulic system service intervals recommended by the manufacturer.

11. Are the milling tools (teeth) replaceable and how often should they be replaced?

Milling tools are replaceable; replacement frequency depends on material being milled and usage intensity. Inspect teeth regularly and replace when worn or chipped to maintain milling efficiency and protect the drum.

12. What safety measures should operators follow when using the milling machine?

Operators should wear appropriate PPE (eye, ear, respiratory and high-visibility protection), be trained on machine operation, ensure stable footing and clear the work area of bystanders, follow lockout procedures before maintenance, and observe all site-specific traffic and safety rules.

13. How can I transport or trailer the ROADWAY Milling Machine between sites?

Due to its 3800 kg weight, transport requires an appropriately rated trailer and vehicle; secure the machine according to local regulations and use suitable ramps or lifting equipment. Check local transport rules and the supplier for recommended transport procedures.

14. Where can I get spare parts, service or warranty information?

Contact your authorized ROADWAY dealer or distributor for genuine spare parts, authorized service, and warranty details. They can also advise on maintenance plans and consumables.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals