B21, China Town Mall, Midrand

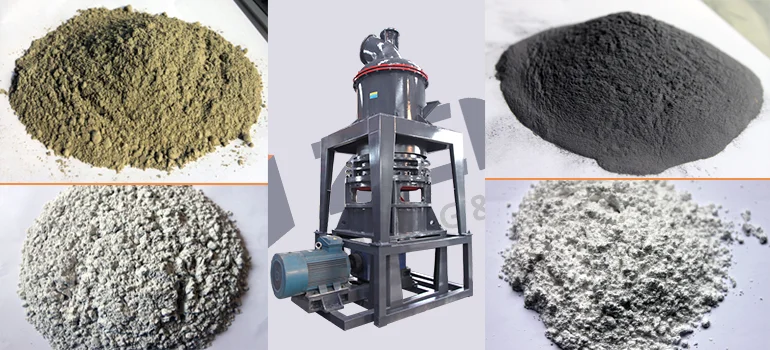

Raymond Mill Fine Powder Processing Machine Mineral Equipment With Capacity 10-35 Tph

- Section : Machinery

- Category : Chemical Machinery

- SKU : 1601173572542

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the capacity of the Raymond Mill Fine Powder Processing Machine?

The Raymond Mill Fine Powder Processing Machine has a capacity ranging from 10 to 35 tons per hour, depending on the feed material.

2. What types of materials can be processed with this machine?

This machine can process more than 300 kinds of stone materials, including calcite, calcium carbonate, dolomite, gypsum, carbon black, kaolin, marble, and many others.

3. What is the fineness range of the powder produced?

The fineness of the powder produced can be adjusted between 325 to 2500 meshes, ensuring a high level of customization.

4. How does the machine ensure uniform particle size?

The machine utilizes centrifugal micro-fluitization technology and multiple grinding chambers to pulverize stones into uniform ultra-micro particles, with over 90% of products below 2500 mesh.

5. Can the machine operate continuously?

Yes, the machine features an external lubricating device that allows for lubrication without shutdown, enabling continuous operation for up to 24 hours.

6. Is the machine environmentally friendly?

Yes, the machine is designed with eco-friendly features, including a silencer and noise elimination room to reduce noise levels and comply with national environmental protection standards.

7. What is the difference between this machine and other types of mills?

Compared to jet grinding mills and stirred mills, this machine has a 40% higher capacity at the same fineness and power, and it produces twice the yield of a ball mill.

8. What industries can benefit from using this fine powder processing machine?

This machine is widely used in various industries, including building, chemical, metallurgy, mining, ceramics, and more, suitable for materials with a Moh's hardness of less than 9.3.

9. What is the working principle of the Raymond Mill?

The working principle involves crushing materials with a hammer crusher, sending them to a storage hopper, and then grinding them in multiple chambers using rollers, followed by classifying the airflow to separate finished powders.

10. What maintenance is required for the machine?

Regular maintenance includes checking the lubrication system, inspecting the grinding rollers and rings, and ensuring that the air filter is clean to maintain optimal performance.

11. What is the maximum inlet size for materials?

The maximum inlet size for materials varies by model, ranging from 10 mm to 20 mm, depending on the specific Raymond Mill model.

12. What are the key features of the fine powder processing machine?

Key features include high pressure spring design, vibration reduction design, strong material applicability, and a superimposed multistage seal for improved sealing performance.

13. How do I adjust the fineness of the powder?

The fineness can be adjusted by modifying the speed of the classifier and the amount of material being fed into the grinding chambers.

14. What type of power supply is required for the machine?

The machine typically requires a three-phase power supply, with different models having varying power requirements ranging from 37 kW to 55 kW.

15. Where can I get support or service for the machine?

Support and service can be obtained through ZENITH, the manufacturer, who provides assistance for installation, operation, and maintenance of the machine.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading