B21, China Town Mall, Midrand

Portable Standing Seam Roofing Panel Roll Forming Machine

- Section : Machinery

- Category : Tile Making Machinery

- SKU : 1600754038915

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is a Portable Standing Seam Roofing Panel Roll Forming Machine used for?

It is a vehicle‑mounted mobile roll forming line that cold‑bends color‑coated steel coil into standing‑seam and other roof/wall panel profiles (including trapezoidal, curved panels and glazed tiles), then rolls, crimps and seals them into continuous sections for lightweight, high‑strength roofing and cladding.

2. Is this machine truly portable and how is it transported?

Yes — the design is for vehicle‑mounted mobile construction use. It can be mounted on a truck or trailer for on‑site forming; alternatively it can be skid‑mounted for relocation between jobs.

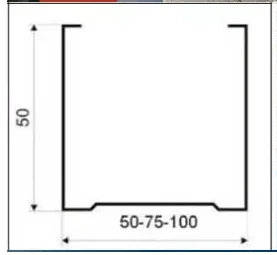

3. Which panel profiles can this machine produce?

It produces standing seam roofing panels and various trapezoidal/tile and curved profiles. Profiles can be standard or fully customized based on your photo or drawing (including double‑layer, 3‑in‑1 multifunctional options).

4. What material and thickness ranges are supported?

The machine is built for color‑coated steel coil. Typical working thickness is 0.3–0.6 mm (common for roofing and wall sheet work); thicker gauges can often be accommodated with design adjustments — please specify material and thickness when ordering.

5. What is the machine's forming speed and production capacity?

Maximum forming speed is 15 m/min. Theoretical continuous strip output at that speed is up to 900 m per hour; actual hourly panel throughput depends on panel length, seaming cycles, cutting frequency and on‑site setup.

6. What are the key technical specifications (power, hydraulic, shafts)?

Main motor power is 4 kW with a cycloidal reducer. Standard electrical supply is 380 V, 50 Hz, 3‑phase (other voltages available on request). Hydraulic cutting uses 40# hydraulic oil. Forming shafts are 70 mm diameter made from 45# quenched and tempered steel.

7. What cutting system does the machine use and what is the cutter material?

It uses a hydraulic cutting system for clean cuts without stopping the machine. The cutting table and dies are made from Cr12 mould steel with quench treatment for long life and good wear resistance.

8. What is the maximum pressing/forming width?

The standard pressing (forming) width is 1000 mm. If you require a different maximum width, we can discuss customization options.

9. What are the frame and structural materials of the machine?

The main frame is fabricated from 350H steel for robust rigidity and durability suitable for mobile and on‑site working conditions.

10. Can the machine form curved (arched) panels and door/wall canopies?

Yes. The horizontal hydraulic arch capability allows formation of trough‑shaped single‑arch and curved panels used for door/wall canopies to divert rain and protect openings and facades.

11. Do you provide installation, commissioning and operator training?

Yes. We provide on‑site installation and commissioning services and operator training. Remote technical support and documentation are also available; specifics are confirmed at order.

12. What routine maintenance is required?

Regular tasks include lubrication of moving parts, periodic hydraulic oil checks/replacement (use 40# hydraulic oil or equivalent), inspection and sharpening/replacement of cutting tools, and checking bolts/shafts for wear. Scheduled maintenance extends service life and ensures consistent product quality.

13. What safety features are included?

Standard safety measures include emergency stop controls, guarding around rotating/pressing parts, hydraulic pressure relief and safe electrical wiring. Operators must follow safety procedures and use PPE; additional safety options can be fitted on request.

14. Can you customize profiles, electrical specifications or add options (servo, speed upgrades)?

Yes. We can customize profile geometry per drawing or photo, change electrical supply to customer requirements, and offer options such as servo drives for higher speeds, different cutters or multi‑function setups (double layer, 3‑in‑1, etc.).

15. What warranty and after‑sales support do you offer?

Typical offerings include a warranty on main mechanical, electrical and hydraulic components (commonly 12 months) plus life‑long technical support and spare parts supply. Exact warranty and support terms are agreed in the sales contract.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading