B21, China Town Mall, Midrand

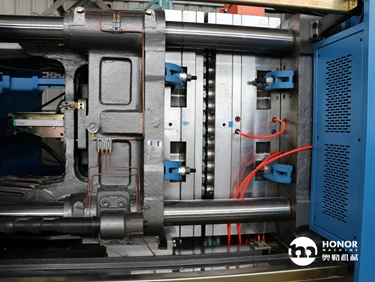

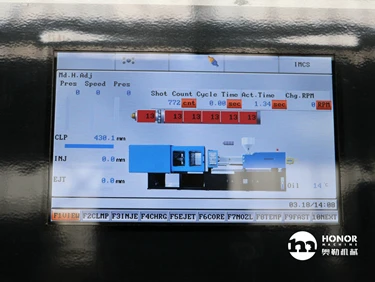

Plastic Chair Socket switch syringe Making Machine Injection Molding Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600430810854

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 07 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the main function of the Plastic Chair Socket switch syringe Making Machine?

The main function of the machine is to produce plastic components such as chair sockets, switches, and syringes through the injection molding process.

2. What technology does this injection molding machine utilize?

This machine adopts European technology, featuring a hydraulic unit with proportional pressure and flow control for adjustable pressure and speed.

3. What are the safety features of the injection molding machine?

The machine includes dual safety systems: one for machine safety and another for electrical safety, ensuring the safety of operators during use.

4. How precise is the temperature control in this machine?

The machine features close-loop PID temperature control, which provides high precision for temperature management during the injection molding process.

5. What materials are used for the molds?

Molds are produced using high-grade materials and hot runner technology, incorporating imported steel for durability and high surface brightness.

6. Can the machine's specifications be customized?

Yes, the machine type can be customized based on the customer's specific inquiries and production needs.

7. What is the weight capacity of the HM-1000A/B model?

The HM-1000A/B model has a clamping tonnage of 1000 KN and a shot weight capacity of 128 grams.

8. What kind of control unit does this machine use?

The machine is equipped with an imported computer designed specifically for injection molding machines, offering multiple functions and precise control.

9. How does the clamping unit work?

The clamping unit features a 5-point twin toggle system designed for strong, rapid, and stable clamping, optimized using modular software.

10. Is the machine easy to operate?

Yes, the equipment is designed with logical operation in mind, making it user-friendly and easy to operate.

11. What is the average good product rate for this machine?

The good product rate can be above 99%, ensuring high-quality production with minimal defects.

12. What are the dimensions of the HM-2050A/B model?

The HM-2050A/B model has dimensions of 175.4 x 1.6 x 1.8 meters.

13. What type of hydraulic components does the machine use?

The machine uses famous imported hydraulic components known for their reliability and low maintenance needs.

14. How does the machine ensure consistent injection quality?

The machine employs balanced double injection cylinder technology, which evenly distributes force during fast injection, enhancing overall injection quality.

15. What is the benefit of using the double injection cylinder technology?

This technology ensures even force distribution, improving the plastic molding condition and the overall quality of the products produced.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading