B21, China Town Mall, Midrand

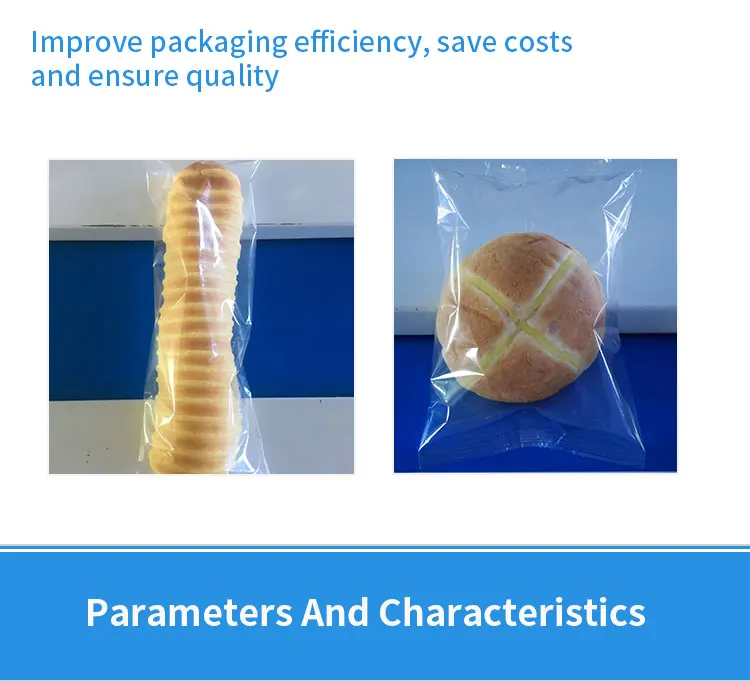

Multi-function High Speed Pack Machine Soap And Food Snacks Packing Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1601007114355

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of products can the Multi-function High Speed Pack Machine handle?

It is designed for granular materials across food, chemical, and consumer goods industries — examples include sugar, salt, coffee powder and similar granules. For powders or liquids, consult the supplier for compatible dosing options.

2. What bag sizes and film width does the machine support?

The machine accepts bag lengths from 50 to 180 mm and bag widths from 17 to 65 mm. Maximum film width is 280 mm. Multi-lane film is supported via the automatic film slitting system.

3. How many lanes can the machine run and can this be customized?

Lane configuration is customizable between 2 and 6 lanes to match your production needs.

4. What is the machine's packing speed?

Packing speed ranges from 30 to 50 cycles per minute, depending on product, bag size, lane count and film used.

5. What measuring range does the dosing system support?

The measuring range is customizable from 1 to 30 ml. Confirm the exact dosing setup with the supplier for your product.

6. What are the machine's power requirements and physical dimensions?

Power supply is 220 V, 50/60 Hz with a power consumption of 3.5 kW. Overall dimensions are approximately 1385 mm (L) × 918 mm (W) × 2005 mm (H) and the weight is about 350 kg.

7. Which operations are automated by the machine?

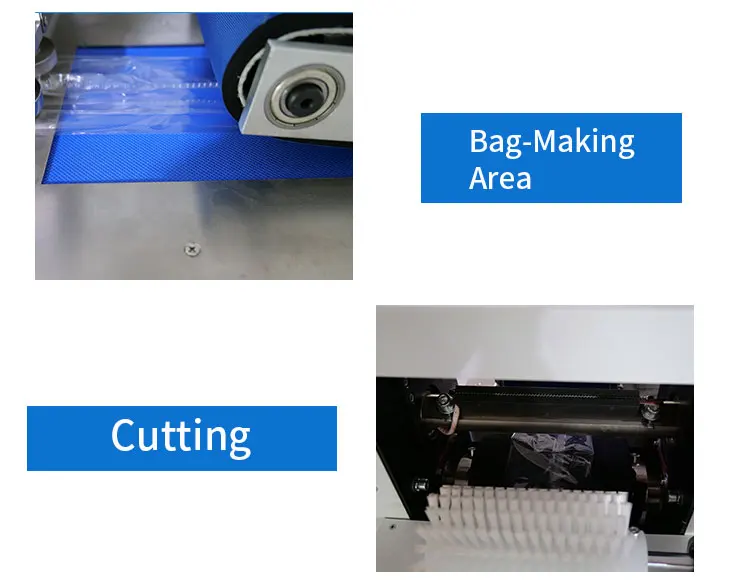

The machine performs full automatic operations including measuring, film cutting and slitting, bag forming, filling, sealing, cutting between bags, counting and applying batch/lot numbers (printing).

8. What type of control system does the machine use?

It uses an intelligent PLC control system with a user-friendly touch screen for setting and adjusting system parameters and production recipes.

9. Is the machine quiet in operation?

Yes — it is equipped with silent stepper motors designed to reduce production noise compared with conventional drive systems. For precise noise-level data, request decibel specifications from the supplier.

10. What kind of film slitting and multi-channel cutting does it have?

An automatic film slitting system provides smooth, flat cuts for multi-lane film, enabling efficient filling and sealing of several channels simultaneously.

11. How easy is format changeover between different bag sizes or products?

Format changes are performed via the PLC touch screen and mechanical adjustments for lane lines and guides. Simple changes can take minutes; more complex conversions may take longer depending on the number of adjustments required.

12. What are the recommended cleaning and maintenance practices?

Perform daily cleaning of product-contact surfaces, check and lubricate moving parts per the manual, inspect sealing jaws and belts for wear, and follow a preventative maintenance schedule. Refer to the supplier's service manual for detailed intervals and procedures.

13. Is the machine suitable for food-grade production and what are the contact materials?

The machine is intended for food industry use, but specific contact-materials (e.g., stainless steel grades, FDA-compliant parts) depend on the model/configuration. Ask the supplier for food-grade or sanitary-contact options and certification details.

14. What after-sales support, spare parts and training are available?

Most suppliers provide operator training, spare parts packages and after-sales service. Warranty terms, spare-parts availability and training scope vary — confirm these details with the vendor before purchase.

15. Can the machine be customized or integrated with additional modules?

Yes. The machine can be customized (lane count, measuring range, dosing heads) and integrated with optional modules such as batch printing, checkweighers, nitrogen flushing, conveyors and infeed systems. Contact sales to specify required options and lead times.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals