B21, China Town Mall, Midrand

Mimage 1.8m Large Format Latex Mesh Belt Printer For PU Leather

- Section : Consumer Electronics

- Category : Digital Printers

- SKU : 1600715896059

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

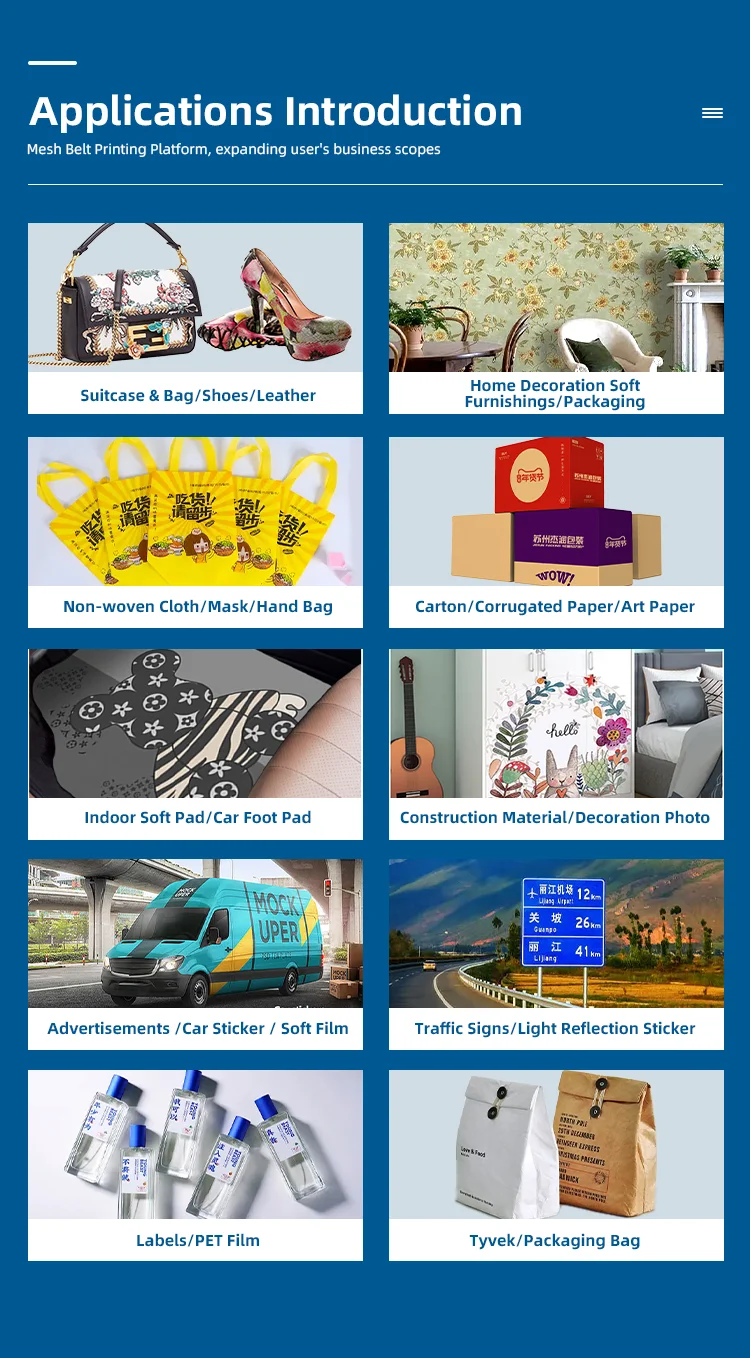

1. What is the Mimage 1.8m Large Format Latex Mesh Belt Printer?

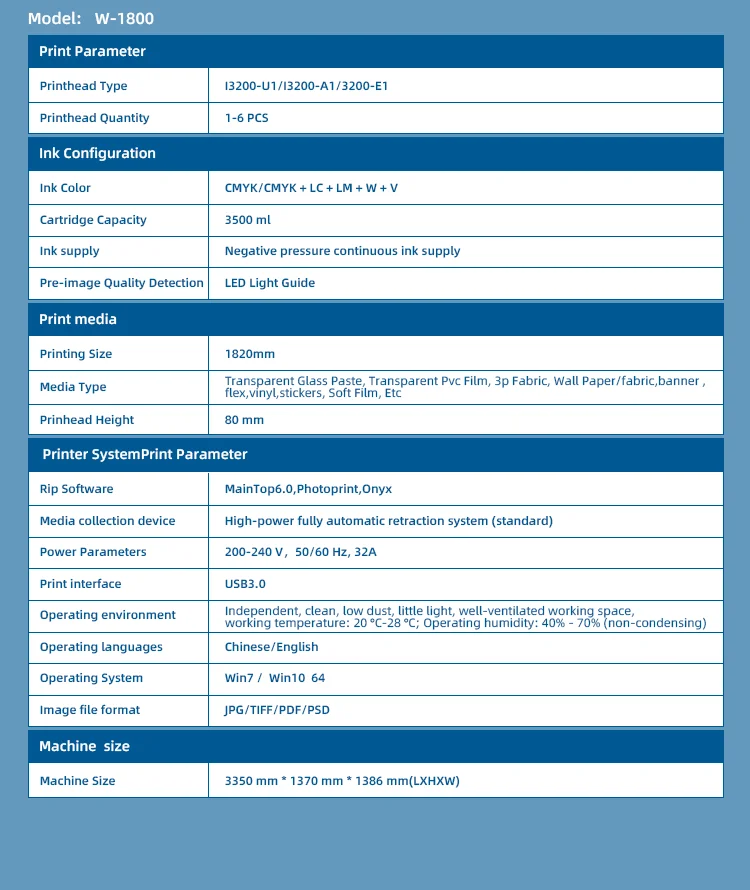

The Mimage 1.8m Large Format Latex Mesh Belt Printer is a UV hybrid inkjet printer engineered for high-quality leather printing (including PU leather) and other large-format media up to 1800 mm wide. It features a mesh-belt suction platform, i3200-U print head, multicolor CMYKW output, and uses water-based latex inks.

2. What maximum print width and resolution does the printer support?

The printer supports a maximum print width of 1.8 meters (1800 mm) and delivers high-quality output up to 2400 DPI for detailed, sharp images.

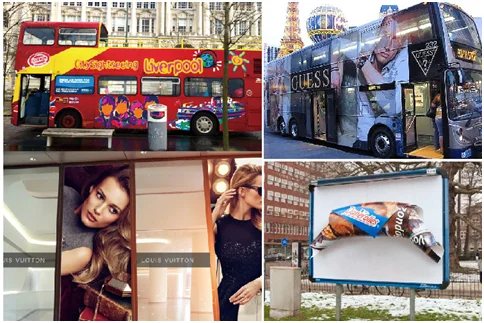

3. Which substrates can this printer handle?

It is primarily designed for leather printing (including PU leather) and is also suitable for wallpaper, advertising rolls, cardboard and other uncoated or coated media compatible with latex and OP inks.

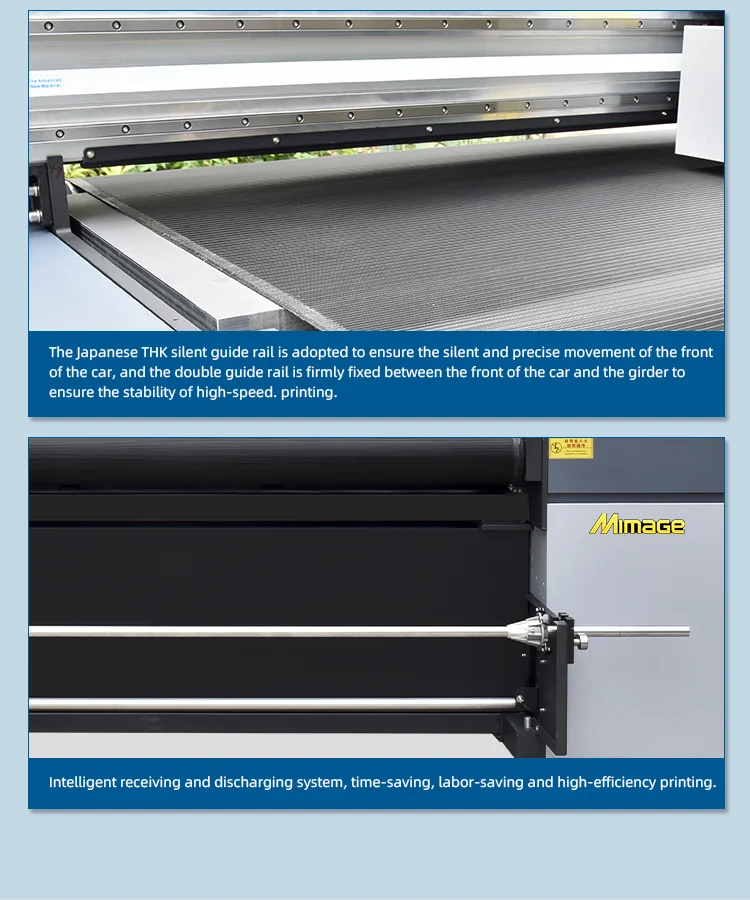

4. What is the purpose of the mesh belt printing platform?

The mesh belt suction platform uses an industrial-grade fan to feed and hold media flat and stable during printing, reducing pulling, wrinkling and adhesion issues to ensure smooth, continuous prints especially on flexible materials like leather.

5. What inks does the printer use and are they eco-friendly?

The printer uses fully water-based latex inks and a unique OP ink. The latex inks are eco-friendly (water-based) with no UV or solvent required. The OP ink enables direct printing on uncoated media without a heating step.

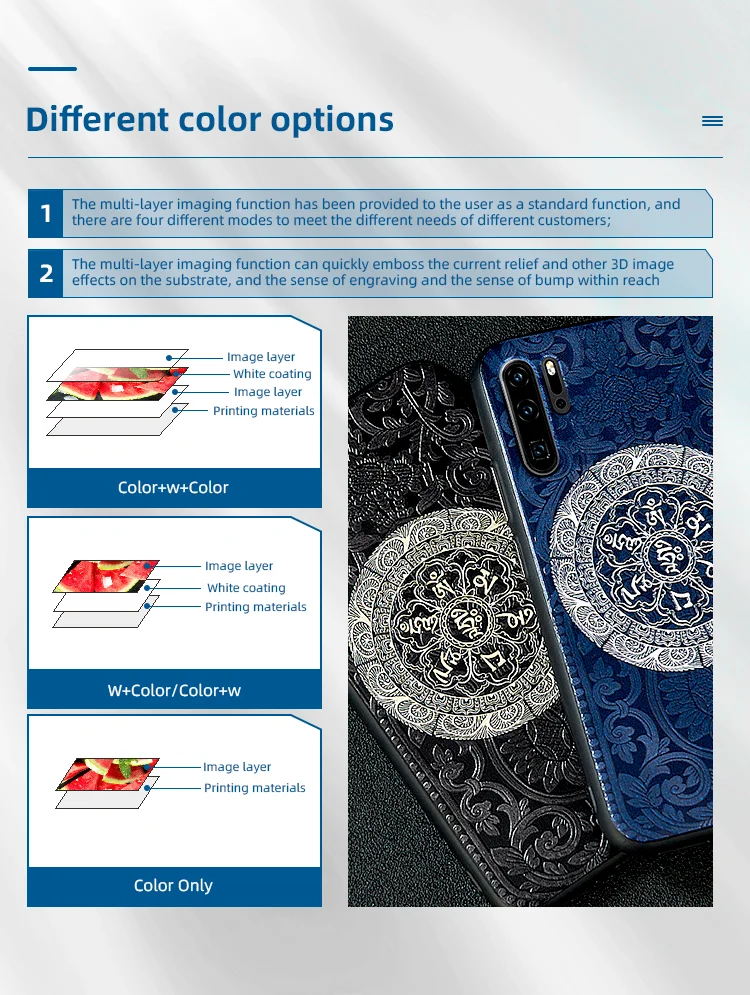

6. How does the printer handle printing on dark or colored materials?

For colored or dark materials the printer uses white ink as a base layer to neutralize the substrate color and produce vibrant, accurate colors. For white substrates you can use OP ink only to reduce cost while maintaining good color performance.

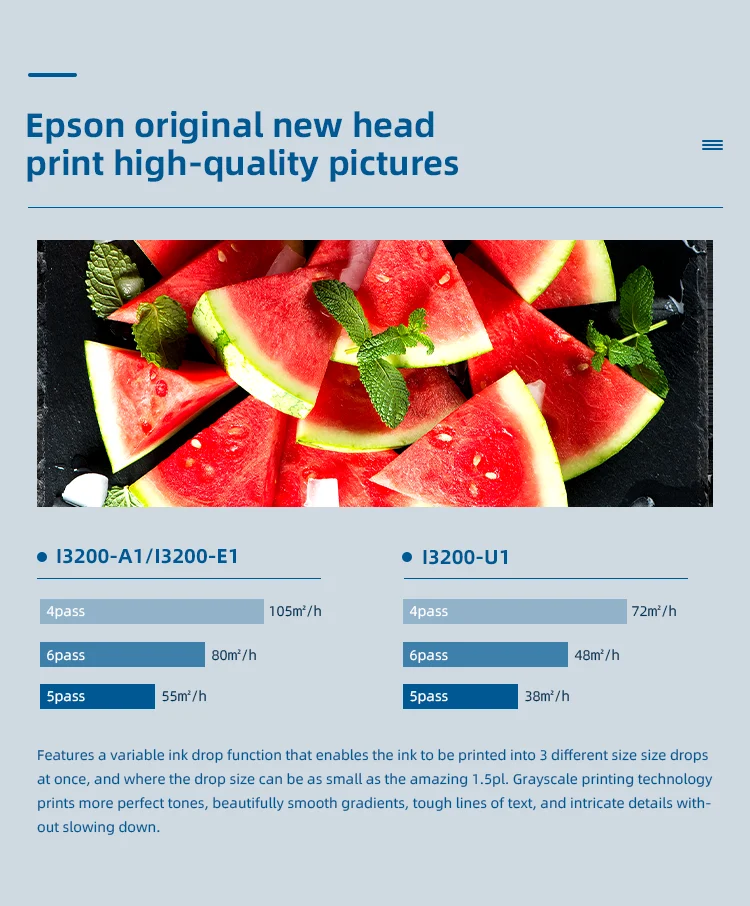

7. Which print head and color configuration does the machine use?

The machine is equipped with the i3200-U print head and supports a CMYKW color configuration (Cyan, Magenta, Yellow, Black, White) for multicolor and specialty white printing.

8. What software is compatible with this printer?

The Mimage printer is compatible with Maintop 6.1 and Photoprint for RIP/driving and design workflow management.

9. What are the machine's dimensions, weight and power requirements?

The printer's dimensions are 3535 x 1515 x 4890 mm and it weighs 240 kg. It operates on 220V at 50Hz/60Hz.

10. Is the machine fully automatic?

Yes. The Mimage printer is described as fully automatic, offering automated feeding, mesh-belt suction transport and adaptive print modes to simplify operation.

11. Does the printer require heating or UV curing during printing?

No external UV or solvent curing is required. The OP ink allows direct printing on uncoated media without needing pre-heating. Latex inks are water-based and typically require less aggressive curing than solvent or UV systems; specific post-processing needs depend on media and application.

12. What maintenance is recommended for optimal performance?

Regular maintenance includes daily nozzle checks and printhead cleaning, using recommended/original latex and OP inks, keeping the mesh belt and feed system free of debris, and operating the printer in a clean, temperature-stable environment. Follow the manufacturer's service schedule for preventive maintenance.

13. What printing speeds can I expect?

Actual printing speed depends on resolution, RIP settings, media type and application. The product specification does not list a single speed value—contact the supplier with your target resolution and media for expected throughput estimates.

14. How can I get installation, training or after-sales support?

For installation, operator training and after-sales support, contact the seller or Mimage representative directly. They can provide on-site setup, training packages and service options tailored to your needs.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading