B21, China Town Mall, Midrand

Manual Plate and Frame Filter Press Machine by SHUANGFA

- Section : Machinery

- Category : Cleaning Equipment

- SKU : 60673822173

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Manual Plate and Frame Filter Press Machine by SHUANGFA?

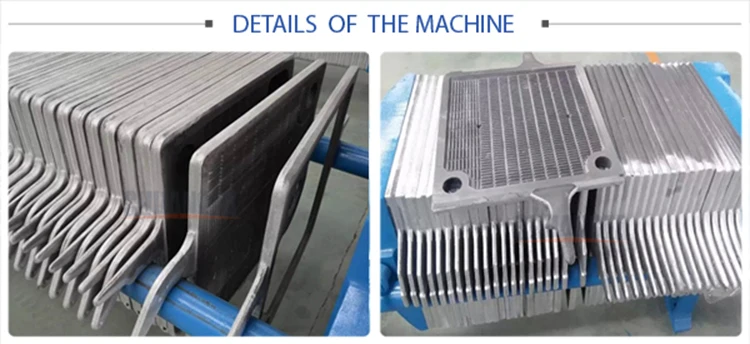

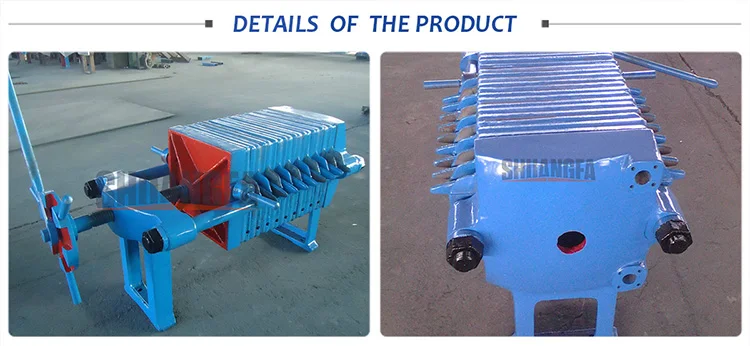

It is a manually operated plate-and-frame filter press designed for solid-liquid separation of various liquids such as oils and maple syrup. It features a cast iron frame, nine 500 x 500 mm filter plates, a 4 m² filter area and a 51 L slurry volume.

2. Which liquids and industries is this filter press suitable for?

The machine is suitable for filtering vegetable and animal oils, food liquids like maple syrup, and many other low-viscosity to medium-viscosity liquids used in food processing, small-scale oil refining, and similar applications.

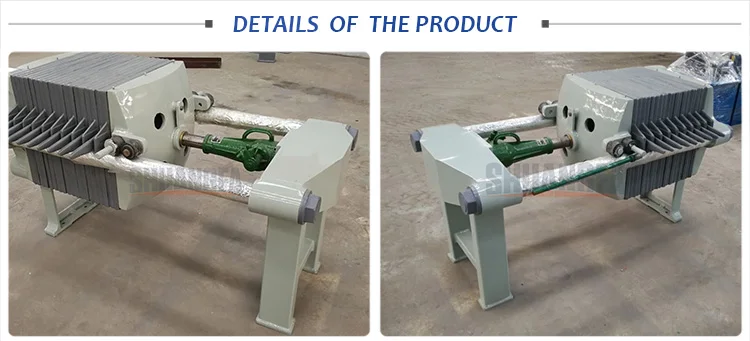

3. How is the press operated?

The press is manual: plate closing, cake formation and cake discharge are carried out by hand-operated mechanisms (handwheel/screw or manual hydraulic depending on customer configuration). Manual operation gives precise hands-on control.

4. What are the key specifications (plates, area, volume, cake thickness)?

The unit includes 9 filter plates sized 500 x 500 mm, a total filter area of 4 m², a slurry holding volume of approximately 51 L, and can form filter cakes up to 25 mm thick per plate pack.

5. What is the construction material and overall weight?

The main frame is cast iron for durability and stability. The machine weighs approximately 1000 kg, providing a stable base during operation.

6. What filter media can I use with this press?

Common filter media include cotton, polyester or polypropylene filter cloths selected by particle size and chemical compatibility. SHUANGFA can recommend cloth types based on your liquid and solids characteristics.

7. How do I remove and clean the filter plates and cloths?

After stopping operation and opening the press, the plates are separated manually to discharge the filter cake. Filter cloths can be removed for washing or replaced. Regular rinsing and periodic cloth inspections are recommended to maintain performance.

8. How much throughput (filtrate volume per hour) can I expect?

Throughput depends on feed concentration, viscosity, feeding method and chosen filter media. Because this is a manual press intended for small-to-medium batches, typical throughput is best estimated by SHUANGFA after reviewing your feed properties and process requirements.

9. Is the machine customizable?

Yes. Color and certain specifications can be customized to meet customer requirements. Additional options like different plate materials, cloth types, or manual closing mechanisms can often be provided—contact SHUANGFA for available customizations.

10. What maintenance does the machine require?

Routine maintenance includes inspecting and cleaning filter cloths, checking plates for damage or warping, lubricating moving parts of the manual mechanisms, inspecting seals and frame integrity, and storing cloths properly when not in use.

11. Are there safety considerations when using this manual press?

Yes. Follow general safety: ensure the machine is on a stable, level surface; lock or block plates before cleaning; use appropriate PPE (gloves, eye protection); avoid placing hands between plates when closing; and follow any local safety regulations for food or oil processing.

12. What spare parts and consumables should I stock?

Common spare items include filter cloths, replacement gaskets or seals, spare filter plates, and components for the manual closing mechanism. SHUANGFA can advise a recommended parts list based on your operating schedule.

13. How is the machine installed and what are the site requirements?

The press should be placed on a level, load-bearing floor able to support ~1000 kg. Provide adequate space for feeding, cake removal and cleaning, and access to wastewater/drainage. SHUANGFA or its distributor can provide installation guidance and dimensions.

14. What warranty and after-sales support are available?

Warranty and after-sales support vary by seller and region. Typical support covers manufacturing defects for a defined period. Contact SHUANGFA or your supplier for specific warranty terms, spare parts availability and technical support options.

15. How long does delivery and lead time take and how is the unit shipped?

Lead time and shipping depend on order details, customization and destination. Because the machine is heavy, it is usually transported by freight/shipping. Contact SHUANGFA or your local dealer with your requirements for a delivery estimate and shipping quote.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading