B21, China Town Mall, Midrand

Insulated Tube Terminal Crimping Machine for VE E Tube Type Pre-Insulated End Terminals

- Section : Machinery

- Category : Metal & Metallurgy Machinery

- SKU : 62388629181

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

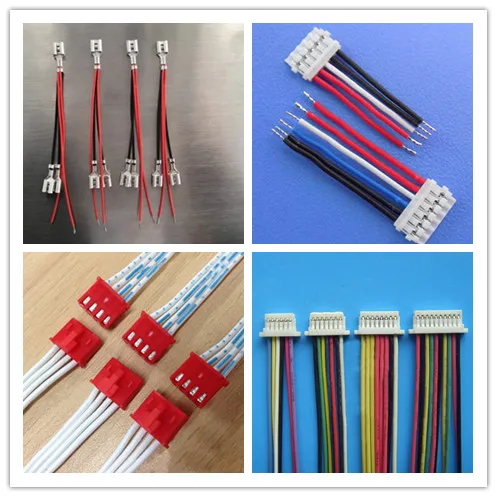

1. What terminals does the Insulated Tube Terminal Crimping Machine support?

It supports computer terminals, DC terminals, AC terminals, single-grain terminals, joint terminals and is compatible with VE E Tube type pre-insulated end terminals. Both vertical and horizontal crimping molds are supported.

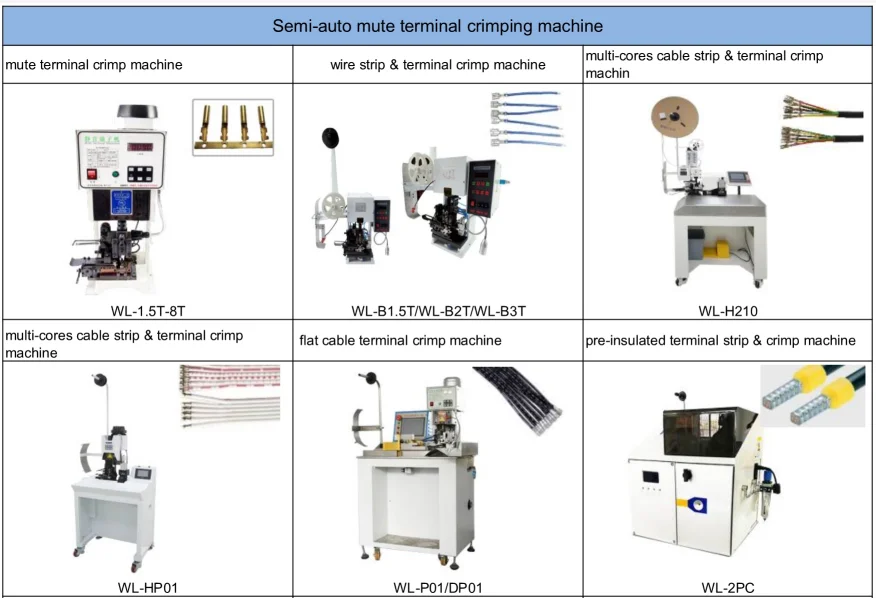

2. Which machine models are available and what are their main specs?

Models: WL-1.5T (1.5 Ton, 1500 KG nominal pressure, 550 W motor), WL-2.0T (2.0 Ton, 2000 KG, 750 W), WL-4.0T (4.0 Ton, 4000 KG, 2200 W), WL-8.0T (8.0 Ton, 8000 KG, 3000 W). Standard stroke 30 mm (40 mm customizable). Power supply: 220V/50Hz or 110V/60Hz.

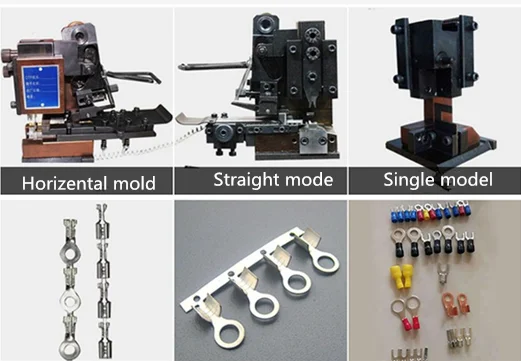

3. How do I change crimping dies and molds for different terminal types?

The machine accepts replaceable crimping molds and applicators. Change the mold to match the terminal design (vertical or horizontal) — dies should be designed according to your terminal. Replacement is straightforward; follow the supplier's mold-change procedure or request onsite guidance if needed.

4. Can the stroke and tooling be customized for special terminals?

Yes. Stroke is standard at 30 mm and 40 mm is available as a customization option. Crimping dies can be customized/designed to match specific terminal geometry and wire sizes.

5. What controls the production speed and how adjustable is the output?

A built-in frequency converter controls motor speed, allowing adjustable production rate. Speed and output can be fine-tuned to match terminal type and production requirements.

6. Does the machine support automatic and manual operation?

Yes. It supports manual mode for setup and low-volume use, and automatic mode for continuous production. Switching between modes is simple and user-friendly.

7. How does the machine track production quantities?

An LED display counts and shows the number of crimped terminals so you can monitor output without external counters.

8. What maintenance is required to keep the machine running reliably?

Lubricate the stamping guide rail every 1–2 hours with 2–3 drops of oil via the top filling hole. Clean the machine daily to remove dirt and excess oil. Grease (butter) the main speed bearing weekly. Follow these routines and the supplier's maintenance instructions.

9. What common problems might occur and how can I troubleshoot them?

Common issues: uneven or incomplete crimps (check die alignment, correct die selection, and pressure settings), jams or feeding errors (clean applicator and terminals, verify feeder alignment), reduced speed or inconsistent strokes (check frequency converter settings and lubrication). If problems persist, contact technical support.

10. Is the machine noisy during operation?

The machine uses a built-in frequency converter and is described as low-noise (semi-auto mute design), so it operates more quietly than many conventional terminal presses.

11. Which industries and applications is this machine best suited for?

It is suitable for terminal processing in electronics, electrical appliances, toys, automotive, motorcycle, and other industries that require crimping pre-insulated end terminals.

12. What power and electrical requirements should I prepare for installation?

Power supply options: 220V/50Hz or 110V/60Hz. Motor power varies by model (550 W to 3000 W). Ensure your facility can supply the correct voltage and sufficient circuit capacity for the selected model.

13. Can you provide samples or pre-production testing for our terminal type?

Yes — most suppliers offer sample testing. Provide your terminal samples and wire specifications so the supplier can design or select appropriate dies and demonstrate crimp quality and cycle rate.

14. Are dies and tooling included, and can they be customized?

Dies are typically designed according to your terminal; tooling arrangements vary by supplier. Custom dies and applicators can be manufactured to match your terminal dimensions — consult the supplier for tooling options and pricing.

15. What safety precautions should operators follow?

Follow standard machine safety: keep hands clear of the crimp area during operation, use guards and emergency stop, ensure proper lockout/tagout when servicing, avoid overfilling oil, and train operators on mode switching and maintenance procedures. Refer to the machine manual for full safety guidelines.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading