B21, China Town Mall, Midrand

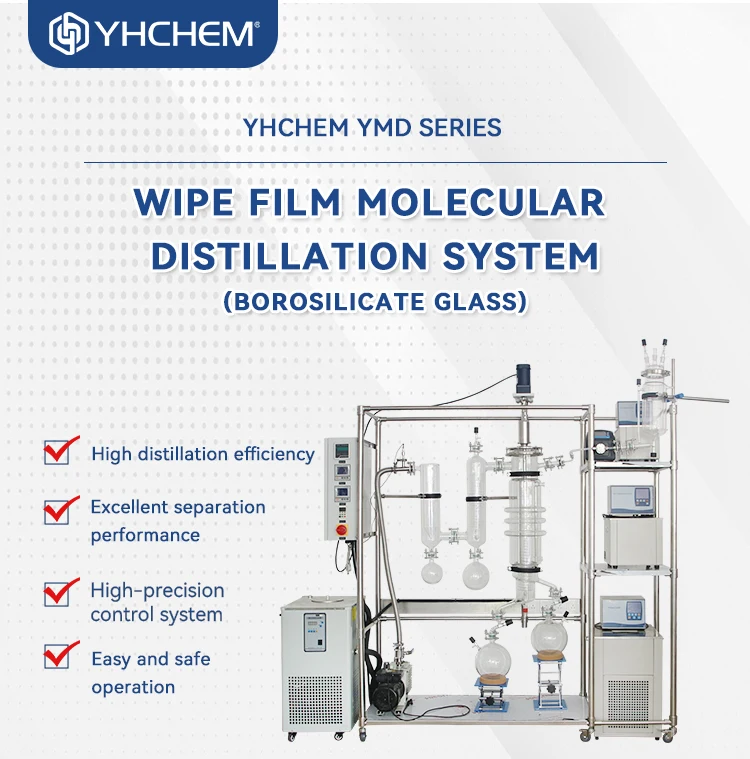

High Efficiency Waste Oil Refining Distillation System

- Section : Machinery

- Category : Chemical Machinery

- SKU : 1601134969548

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary application of the High Efficiency Waste Oil Refining Distillation System?

The system is designed for both lab and industrial-scale applications, primarily used in the food, beverage, chemical, and pharmaceutical industries for waste oil refining.

2. How does the wiped film distillation technology benefit the refining process?

Wiped film distillation provides high-quality output with minimal waste, enhancing the efficiency and effectiveness of the refining process.

3. What is the power rating of the motor used in the system?

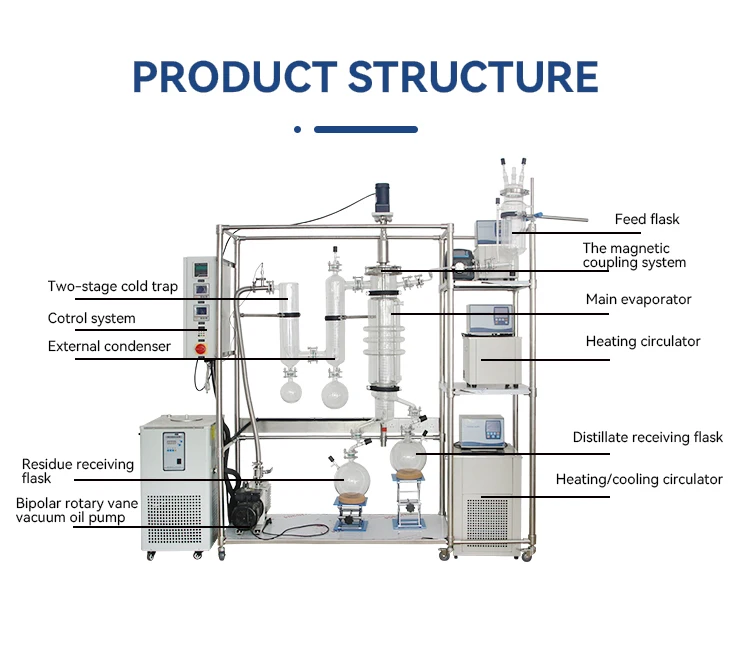

The system is powered by a 120 kW motor, ensuring strong and reliable performance for large-scale operations.

4. What are the dimensions of the High Efficiency Waste Oil Refining Distillation System?

The system has compact dimensions of 1800 x 660 x 1990 mm, making it suitable for both lab and industrial spaces.

5. What safety features are included in the system?

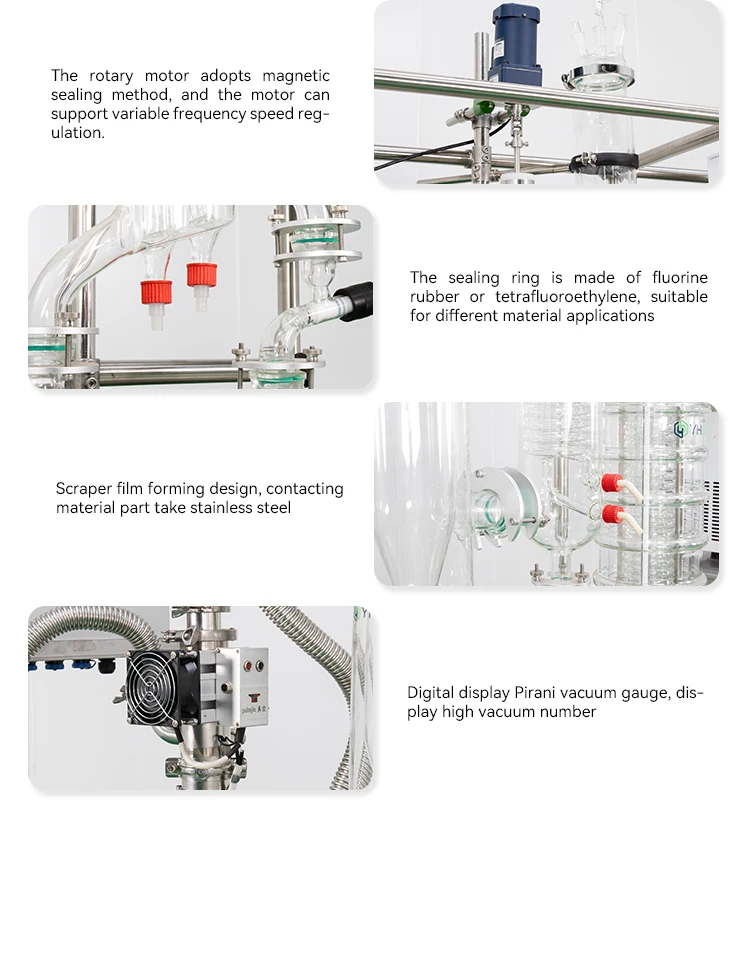

The system features a magnetic sealing system for leak-proof connections and can include explosion-proof devices to prevent safety issues like overheating.

6. Can the system handle different types of materials?

Yes, the system is versatile and can be customized for various materials, making it suitable for applications in multiple industries.

7. What is the maximum working temperature for the distillation process?

The system can operate at a maximum working temperature of up to 300°C.

8. How is the feeding process controlled in the system?

The system is equipped with a high-precision PTFE valve that allows for accurate feeding, enhancing the overall distillation process.

9. What is the evaporation area of the system?

The system features a large evaporation area of 0.06 m², which enhances processing efficiency and increases throughput.

10. What types of industries can benefit from using this distillation system?

Industries such as chemical, pharmaceutical, food processing, biotechnology, new material development, and petrochemicals can benefit from this distillation system.

11. Does the system allow for customization?

Yes, the system supports various customizations, including mixed molecular distillation systems, full jackets, and explosion-proof features.

12. Is the system easy to operate and maintain?

Yes, the system is designed for ease of use and maintenance, allowing users to easily adjust parameters to meet different distillation requirements.

13. What type of control system does the distillation system use?

The system includes a high-precision control system that can precisely manage parameters such as temperature, pressure, and flow rate during distillation.

14. What are the collection capacities for light and heavy components?

The system includes collection bottles with a capacity of 0.5 liters for light components and 25 liters for heavy fractions.

15. What materials are used in the construction of the distillation system?

The system is constructed with high borosilicate glass 3.3, which offers corrosion resistance, high-temperature resistance, and thermal shock resistance.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading