B21, China Town Mall, Midrand

Gold Copper Ore Mining Equipment Processing Line Gold Copper Extracting Plant High Recovery Rate

- Section : Machinery

- Category : Chemical Machinery

- SKU : 1601115218792

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the capacity of the Gold Copper Ore Mining Equipment Processing Line?

The capacity of the processing line is 200TPD (tons per day), designed to efficiently process lithium ore.

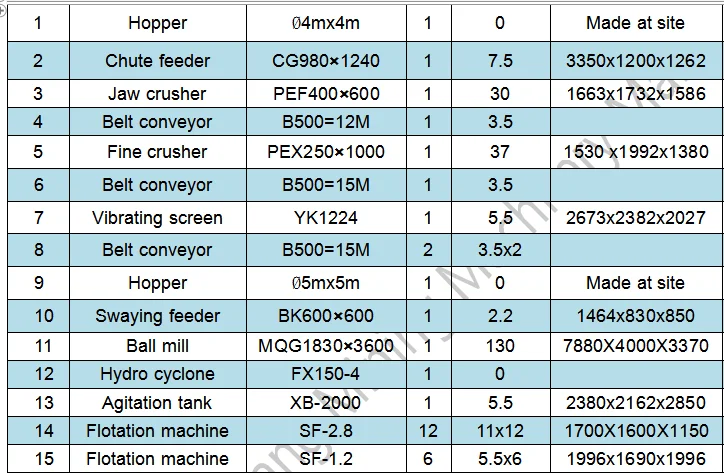

2. What is included in the Gold Copper Extracting Plant equipment list?

The equipment list includes jaw crushers, fine crushers, vibrating screens, ball mills, classifiers, flotation machines, and dryers, among others, necessary for the complete processing of gold and copper ores.

3. How does the primary crushing process work?

In the primary crushing process, the ore is sent to a jaw crusher, which breaks it down into smaller pieces suitable for further processing.

4. What is the role of the ball mill in the processing line?

The ball mill is used for fine crushing and grinding of the ore, ensuring that the material is reduced to the desired particle size for further classification.

5. Can the equipment handle different types of ores?

Yes, the equipment is versatile and can be used to process different types of ores, including gold, copper, and lithium, by adjusting the additives used in the flotation process.

6. What is the purpose of the spiral classifier?

The spiral classifier is used to clean and group the ore mixture based on the sedimentation rate, allowing for effective separation of different particle sizes.

7. How do you achieve high recovery rates in this processing line?

High recovery rates are achieved through a combination of precise crushing, effective classification, and the use of flotation machines tailored to the specific characteristics of the ores being processed.

8. What happens after the ore is separated in the flotation machine?

After separation, the desired ore typically contains a lot of water, which is then concentrated using a thickener before being filtered and dried to produce dry concentrate ore.

9. Is there an energy-saving feature in the processing line?

Yes, the processing line is designed for energy efficiency, including a three-stage crushing process that allows for a larger feeding size into the ball mill, reducing energy consumption.

10. What additives are used in the flotation process?

Different additives are used depending on the type of ore being processed, which helps in effectively separating the desired minerals from the mixture.

11. How is the final product dried?

The final product is dried using a rotary dryer after passing through a thickener and filter to remove excess water, resulting in a dry concentrate ore.

12. What are the steps involved in the lithium ore beneficiation process?

The steps include primary crushing, secondary crushing, screening, grinding, classifying, ore separating, concentrating, and finally drying.

13. What is the importance of using a hydro cyclone in the process?

A hydro cyclone is used instead of a spiral classifier when needed, providing efficient classification and separation of the ore based on specific gravity.

14. How does the vibrating screen function in the processing line?

The vibrating screen is used to separate and classify materials based on size, ensuring only the appropriately sized particles move on to the next stage of processing.

15. Can this processing line be customized for specific mining operations?

Yes, the processing line can be customized based on specific operational requirements, including equipment selection and process adjustments to suit particular types of ore.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading