B21, China Town Mall, Midrand

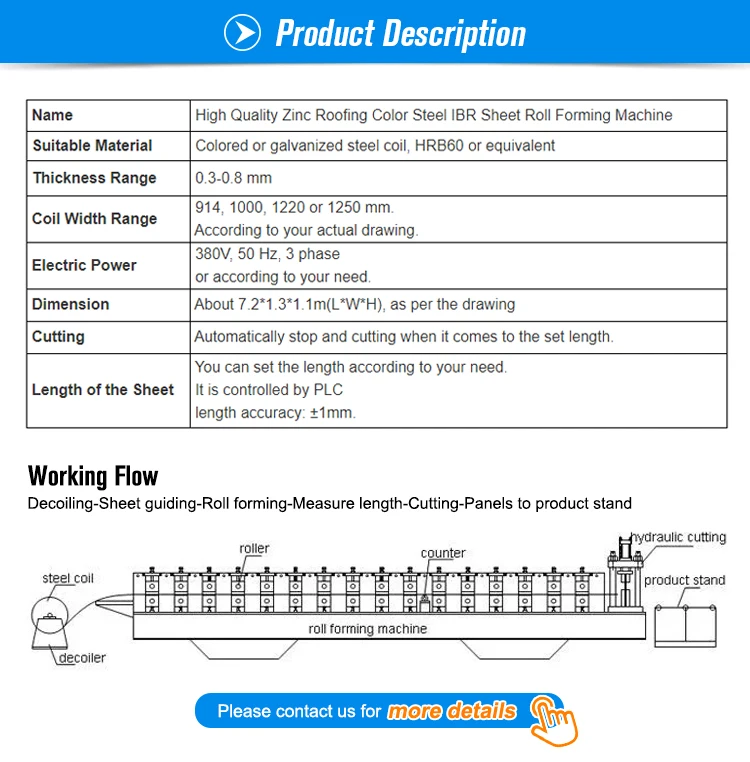

Fully Automatic Corrugated Roll Roof 950 Glazed Tiles Making Machine

- Section : Machinery

- Category : Construction Machinery

- SKU : 1600965639831

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials can the Fully Automatic Corrugated Roll Roof 950 Glazed Tiles Making Machine process?

It is designed to process colored or galvanized steel coils and steels of HRB60 grade or equivalent.

2. What thickness range of sheet can this machine handle?

The machine supports sheet thicknesses from 0.25 mm to 0.7 mm.

3. What coil widths are compatible with the machine?

Standard compatible coil widths include 914 mm, 1000 mm, 1220 mm and 1250 mm. Other widths can be accommodated according to your actual drawing.

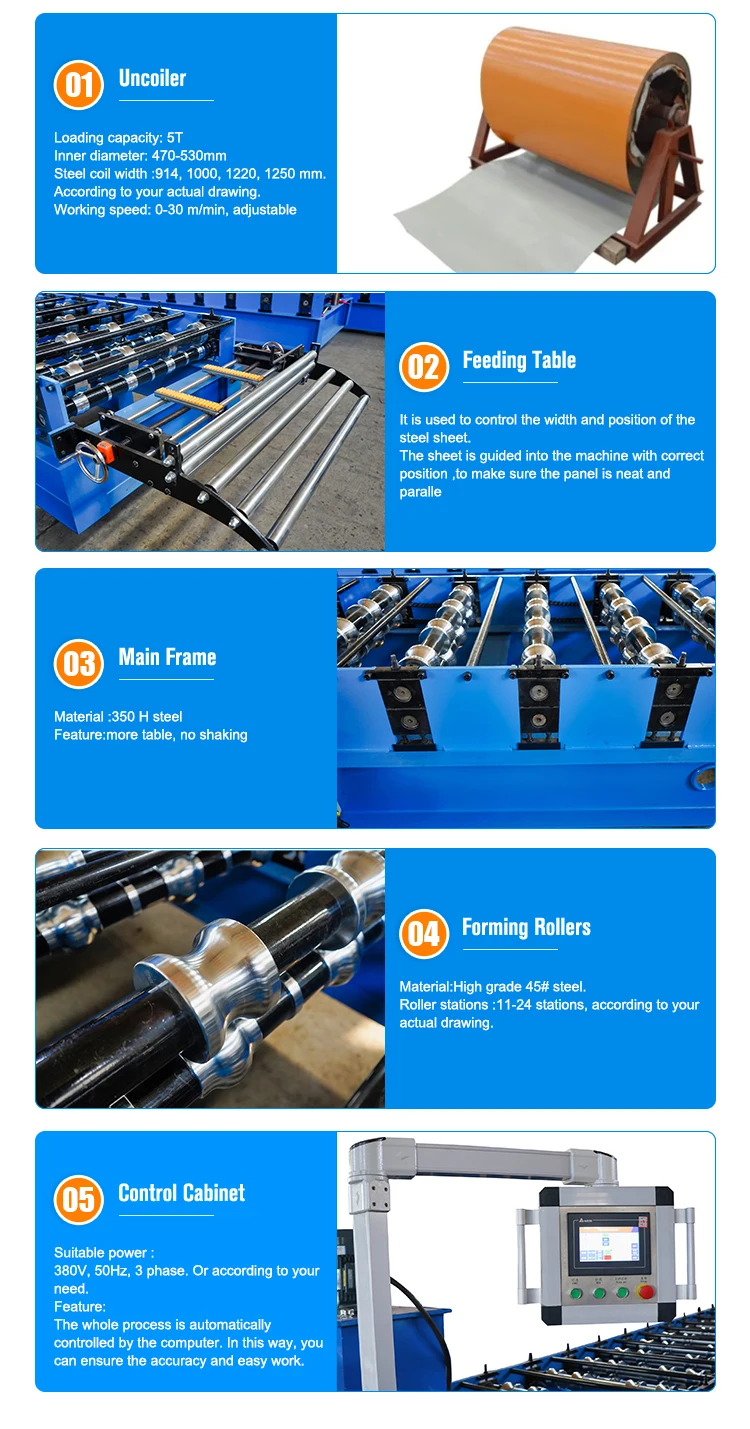

4. What electrical power supply is required?

Standard electrical supply is 380 V, 50 Hz, three-phase. The power configuration can be adapted to your local requirements on request.

5. What are the machine dimensions and footprint?

Approximate overall dimensions are 7.2 m (L) × 1.3 m (W) × 1.1 m (H). Exact layout may vary according to final drawing and optional equipment.

6. How does the cutting system work and how accurate are the sheet lengths?

The cutting unit automatically stops and cuts when the preset length is reached. Length is controlled by PLC with an accuracy of ±1 mm.

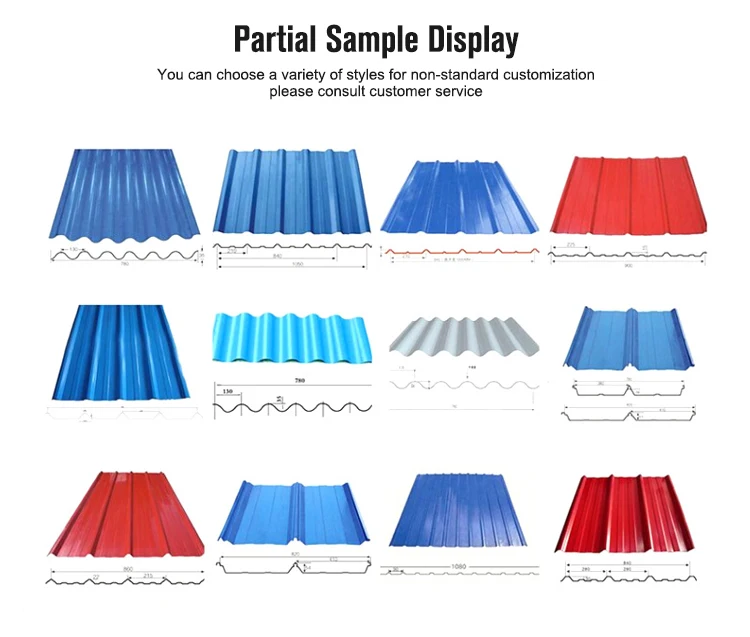

7. Can the machine produce glazed tile profiles other than the standard 950 profile?

Yes — profiles and tooling can be customized according to your drawings. Provide the profile drawing to the supplier to confirm feasibility and tooling requirements.

8. What level of automation and control does the machine have?

The machine is fully automatic and uses PLC control for profile length and process coordination. Specific HMI, PLC brand and control features can be chosen per order.

9. What is the typical production speed or output of the machine?

Output depends on material, profile complexity, cutting frequency and setup. Production speed varies by job; please consult the supplier with your profile and target output for a quoted capacity.

10. What are the installation, commissioning and training arrangements?

Suppliers typically offer onsite installation and commissioning, plus operator training. Exact terms (duration, travel costs, language) should be agreed with the manufacturer.

11. What routine maintenance is required?

Regular maintenance includes cleaning and lubrication of rollers and bearings, inspection and replacement of cutting blades, checking electrical connections and PLC backups, and monitoring wear parts. Follow the manufacturer's maintenance schedule.

12. Are spare parts and after-sales service available?

Yes — genuine spare parts, wear parts and technical support are commonly provided. Confirm available parts, lead times and service agreements with the supplier before purchase.

13. What safety features does the machine include?

Typical safety features include emergency stop buttons, safety guards around moving parts and electrical protection. Specific safety devices and compliance with local regulations should be confirmed with the manufacturer.

14. How is the machine packaged and shipped?

Machines are normally prepared for export packing (wooden crates or frames) and shipped by sea or land. Packaging and shipping dimensions/weights will be provided by the supplier based on the final configuration.

15. Can the electrical configuration or other options be customized for local requirements?

Yes. Electrical specifications (voltage/frequency), optional components (decoiler, leveling machine, hydraulic/servo cutter, stacking table, etc.) and other custom requirements can be discussed and supplied to meet local needs.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading