B21, China Town Mall, Midrand

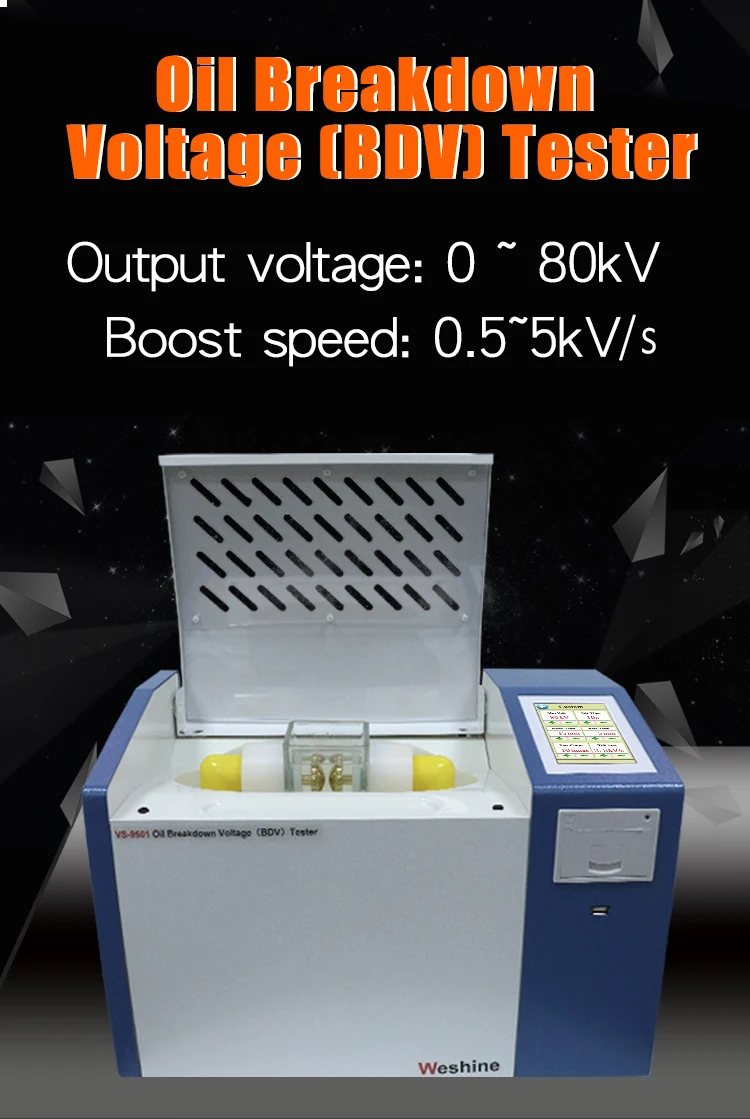

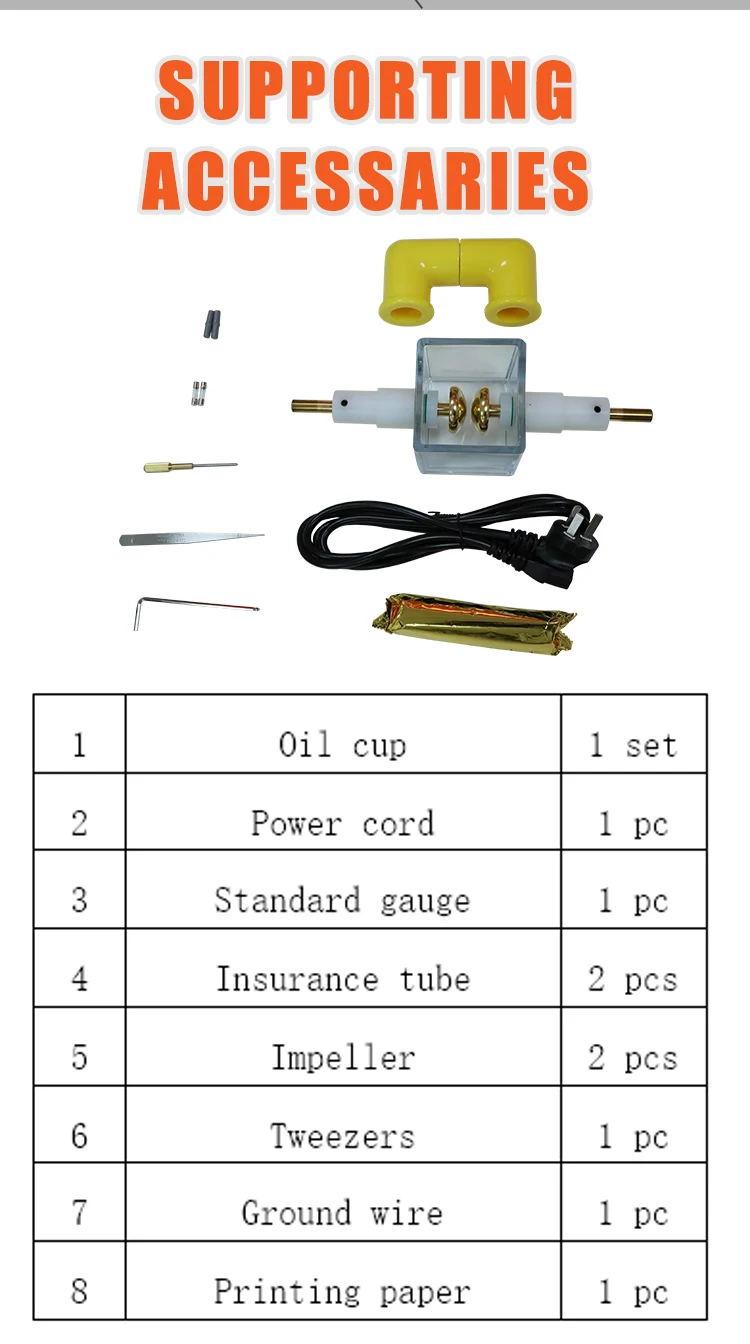

Full Automatic Dielectric Oil Lab Testing Equipment Breakdown Voltage Analyzer Transformer Oil BDV Tester

- Section : Consumer Electronics

- Category : Test Instruments

- SKU : 1600605216197

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the VS-9501B Full Automatic Dielectric Oil BDV Tester?

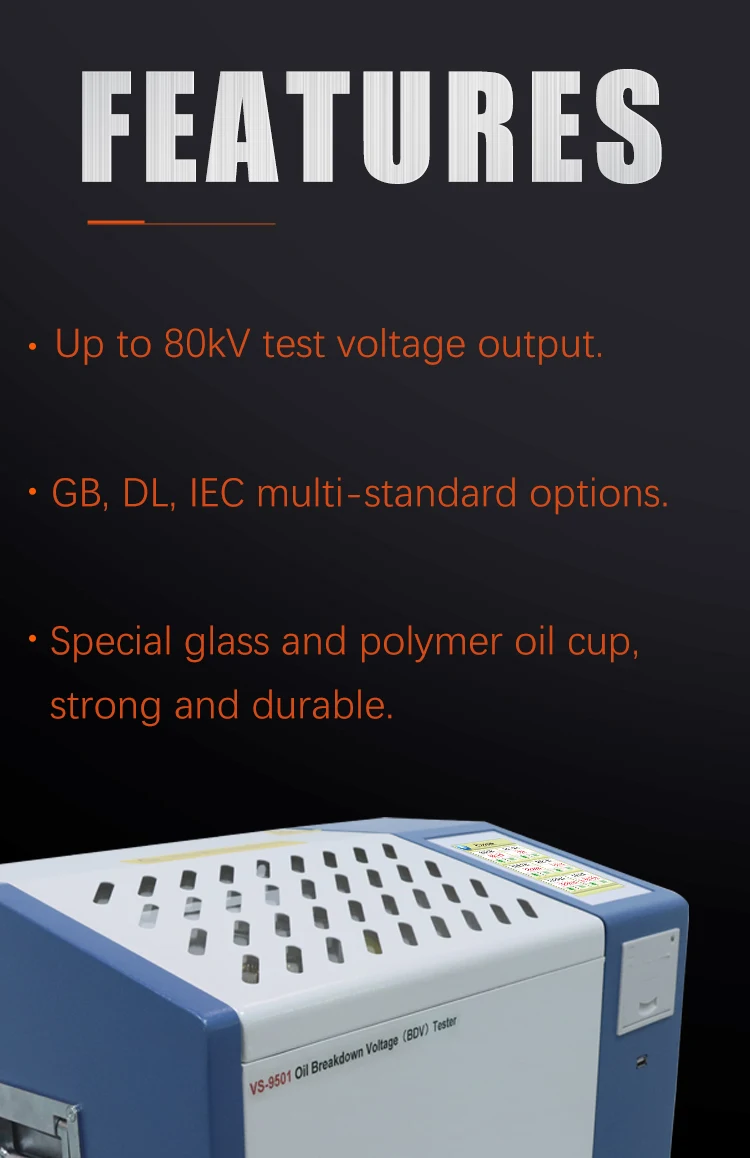

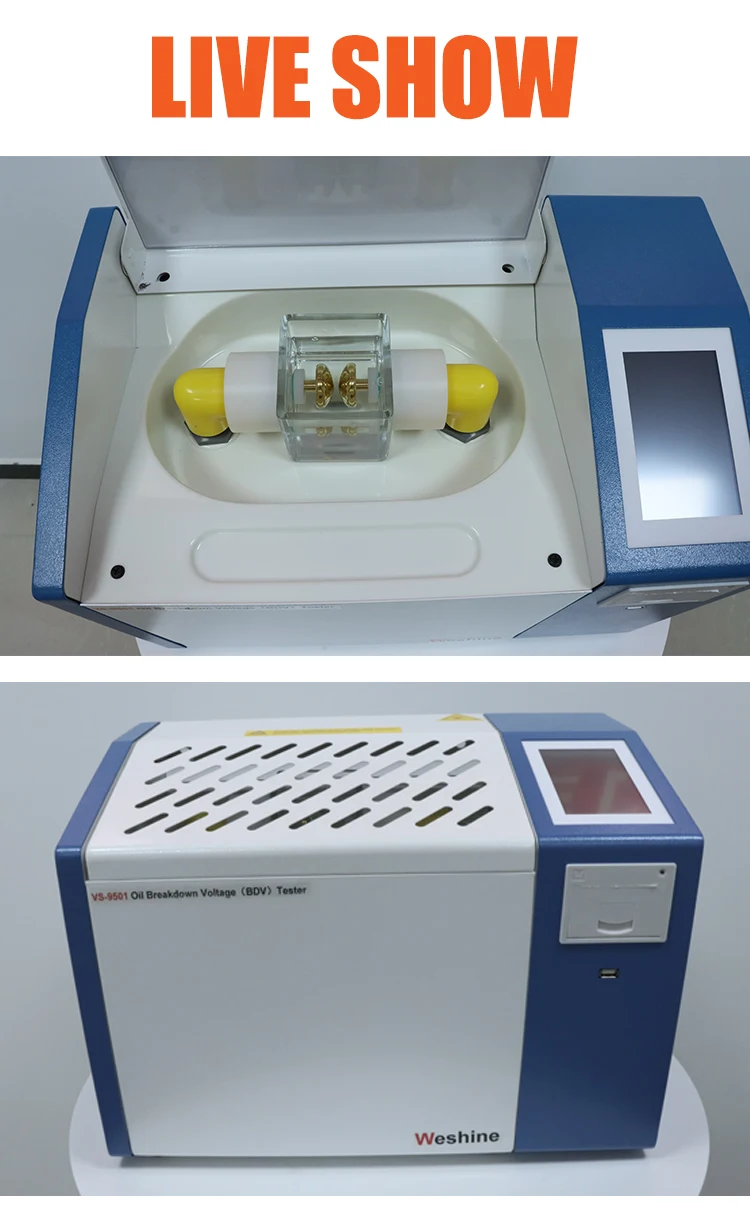

The VS-9501B is a fully automatic breakdown voltage (BDV) tester designed to measure the dielectric strength of transformer oils and other insulating fluids. It controls voltage rise precisely and provides results that comply with international testing standards for transformer maintenance, quality control and R&D.

2. Which international standards does this tester meet?

The VS-9501B supports and is pre-programmed for multiple international standards including IEC 60156, ASTM D877, ASTM D1816, BS EN 60156, CEI EN 60156, VDE 0370-5, AS1767.2.1, JIS C2101, GB/T507, DL/T 846.7 and DL/T 429.9. It is also certified to CE, EMC, LVD and ISO requirements.

3. What is the test voltage range of the unit?

The tester offers a wide test range up to either 0–80 kV or 0–100 kV depending on model/configuration, covering the voltage needs for most dielectric oil testing applications.

4. What voltage raising speeds are available?

Voltage raising speed is adjustable. The product documentation lists a configurable range from about 0.5 to 5 kV/s, with common operational settings in the 2.0–3.5 kV/s range for standard BDV testing.

5. What is the electrode gap and why does it matter?

The standard electrode gap is 2.5 mm, which is the industry-accepted spacing for many BDV tests. Using the specified gap ensures test results are comparable to the referenced standards and between laboratories.

6. How many samples can be tested at once?

The VS-9501B supports multiple sample configurations including single-cup, triple-cup and six-cup arrangements, allowing batch testing for higher throughput or individual checks as needed.

7. What is the boost capacity of the tester?

The unit includes a 1.5 kVA booster to supply consistent high-voltage during tests, ensuring stable and repeatable breakdown measurements.

8. What are the physical size and weight of the tester?

The VS-9501B is designed to be compact and portable. Depending on configuration, typical footprints fall roughly in the ranges 320–500 mm (W) x 280–360 mm (D) x 420–460 mm (H) and weights around 22–34.5 kg. Refer to the specific model datasheet for exact dimensions and weight.

9. What power supply or electrical requirements does the tester need?

The product documentation states a power distortion rate of <1% and uses a mains supply suitable for the booster and control electronics. Exact voltage and frequency requirements depend on regional model configuration—consult the user manual or datasheet for your unit's rated input (e.g., 110/220 VAC, frequency).

10. How automated is the testing process and what does 'full automatic' mean?

'Full automatic' means the tester can perform the BDV test sequence—including voltage ramping, detection of breakdown events, cut-off and recording—without manual intervention. It reduces operator variability and helps ensure tests conform to pre-programmed standard procedures.

11. What safety features are included?

The unit is designed and certified to international safety standards (CE, LVD, EMC). Typical protective features include controlled high-voltage cut-off on breakdown detection, grounding provisions, and interlocks or shielding to protect the operator. Always follow the supplied safety instructions and local electrical safety practices.

12. How are results recorded and reported?

The tester provides automatic result capture per test cycle in accordance with the selected standard. For details about built-in displays, printing or PC communication (data export, logging or software packages), check the specific model options or contact the manufacturer for available interfaces and software packages.

13. How often should the VS-9501B be calibrated and maintained?

Regular calibration and preventive maintenance are recommended to ensure accurate BDV results. Typical practice is annual calibration by a qualified service provider or more frequently if used heavily or in critical applications. Routine maintenance includes cleaning electrodes, checking insulation and connections, and verifying booster performance—refer to the user manual for a maintenance schedule.

14. What sample volume and preparation are required?

Sample volume depends on the cup configuration (single, triple, six-cup). Oils should be prepared and tested following the chosen standard (e.g., filtration, degassing, temperature control). Consult the applicable standard (IEC/ASTM) and the instrument manual for precise sample volumes and preparation steps.

15. Which applications and environments is the VS-9501B best suited for?

The VS-9501B is suitable for transformer oil testing in power plants, utilities, manufacturing quality control, routine maintenance, and research laboratories studying dielectric fluids. It is intended for indoor laboratory or workshop use in environments that meet the specified ambient and safety conditions in the manual.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading