B21, China Town Mall, Midrand

EZ-300 Hydraulic Battery-Powered Cable Crimping Tool

- Section : Electrical & Tools

- Category : Tools & Hardware

- SKU : 996930201959

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 04 Feb, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the EZ-300 Hydraulic Battery-Powered Cable Crimping Tool?

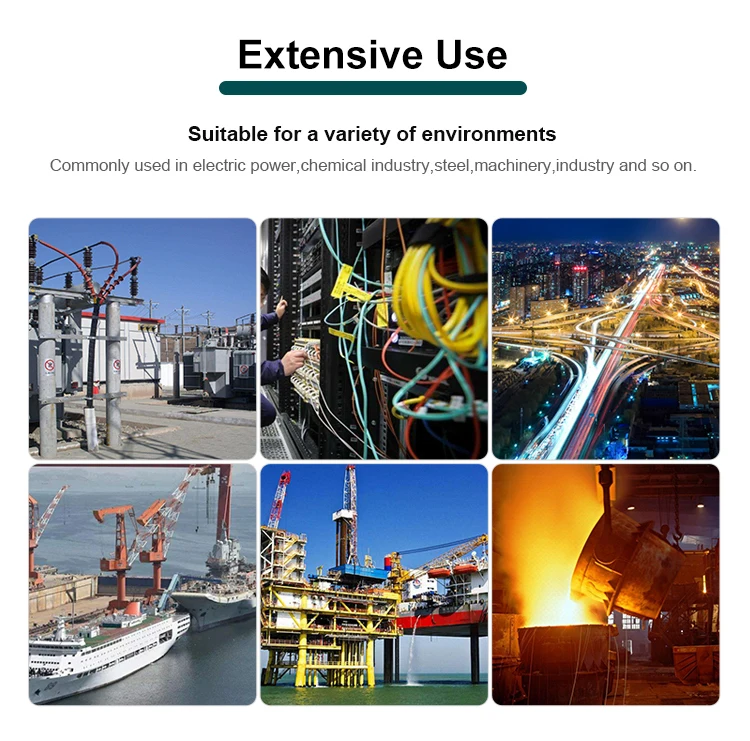

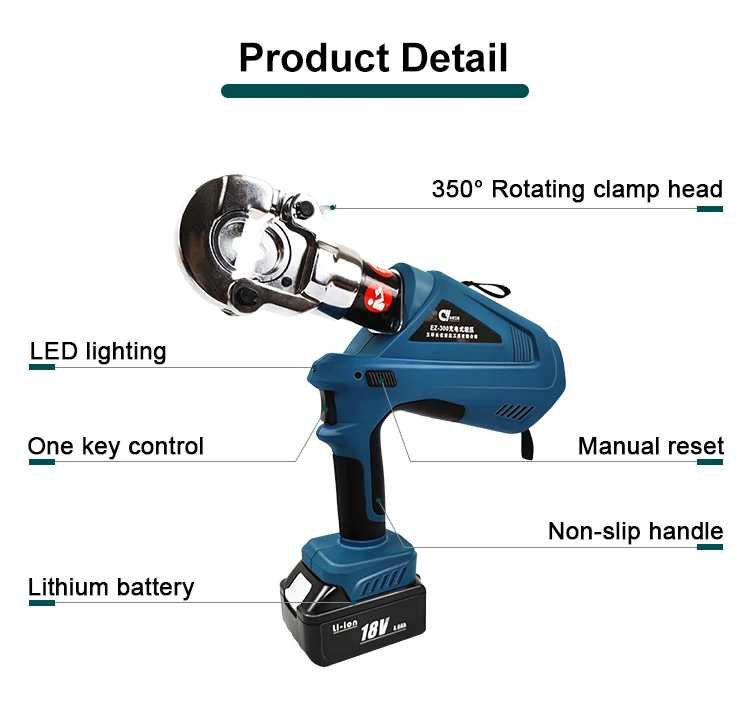

The EZ-300 is a portable, battery-driven hydraulic crimping tool designed to compress cable lugs and connectors onto power and control conductors. It combines a compact hydraulic head with a rechargeable battery pack for fast, on-site crimping without an external pump.

2. What types of connectors and conductors can it crimp?

The tool is intended for common power and grounding connectors used on copper and aluminum conductors. Compatibility depends on the die set and crimp profile; always use dies rated for the specific connector type and size.

3. What cable and connector sizes does the EZ-300 support?

Supported sizes depend on the interchangeable die set installed. The tool accepts a range of dies to cover small-to-large conductor diameters. Check the die catalog or the product datasheet for the exact size range supported by the die sets you plan to use.

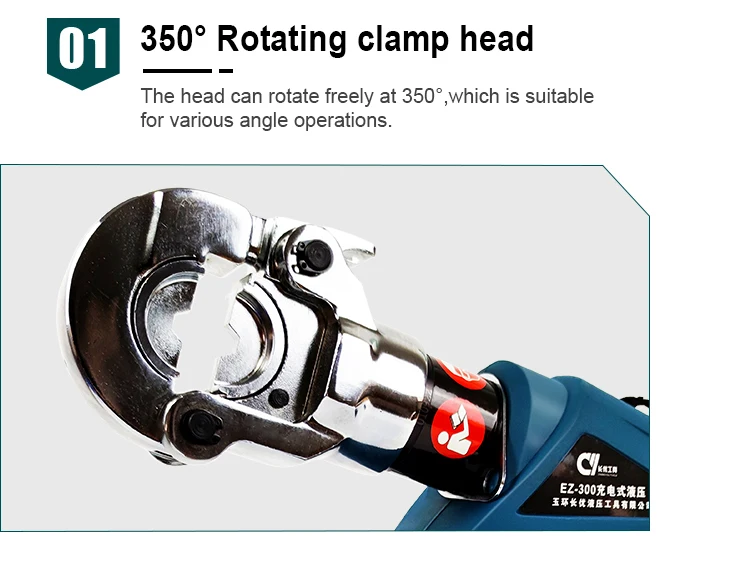

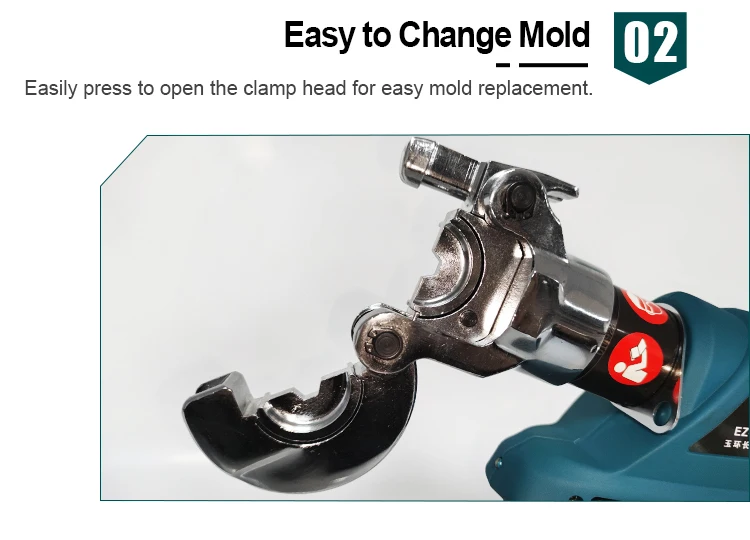

4. How do I change crimping dies?

Power off the tool and remove the battery. Open the crimp head retaining mechanism (follow the user manual for your model), remove the installed die, and insert the new die pair until they lock. Verify correct orientation and secure the retaining latch before operation.

5. How long does the battery take to charge and how many crimps per charge can I expect?

Charging time and runtime vary with battery capacity and usage. Typical lithium battery packs charge in a few hours. Crimps per charge depend on crimp size and frequency; consult the product datasheet or your distributor for measured runtimes for your configuration.

6. Are replacement batteries and chargers available?

Yes. Replacement batteries and chargers are available from the manufacturer or authorized distributors. Use only manufacturer-approved batteries and chargers to ensure safe operation and to avoid voiding the warranty.

7. What safety precautions should I follow when using the EZ-300?

Wear appropriate PPE (safety glasses, gloves). Keep fingers and loose clothing away from the crimp head during operation. Verify the connector and die alignment before firing. Do not exceed the recommended connector or die sizes. Follow lockout/tagout procedures when working on energized circuits.

8. How do I maintain the tool to ensure reliable operation?

Keep the tool clean and free of debris, regularly inspect dies for wear or damage, check hydraulic fittings for leaks, and keep the battery contacts clean. Replace worn seals and O-rings as needed. Follow the maintenance schedule and procedures in the user manual.

9. How often should the EZ-300 be calibrated or tested?

Calibration and performance testing frequency depends on usage and workplace requirements. Many organizations perform verification annually or after a set number of crimps. Follow your company’s quality procedures and the manufacturer's recommendations for calibration and crimp testing.

10. What troubleshooting steps should I take if the tool will not build pressure or crimp properly?

First ensure the battery is charged and properly seated. Check for hydraulic fluid leaks, damaged hoses, or loose fittings. Inspect dies for damage or incorrect installation. If air is trapped in the hydraulic system, bleed according to the manual. If problems persist, contact authorized service.

11. Can the EZ-300 be used in extreme temperatures or outdoor conditions?

The tool is designed for field use, but ambient temperature and weather can affect battery performance and hydraulic fluid viscosity. Check the operating temperature range in the product manual and avoid using the tool in conditions outside those specifications. Store and charge batteries within recommended temperature ranges.

12. Does the tool meet industry crimping standards and certifications?

Compliance with specific standards (for example IEC, ISO, or industry-specific crimp profiles) and certifications varies by model and configuration. Refer to the product datasheet, label, or certificate of conformity provided by the manufacturer for exact certification and standards compliance.

13. What accessories and spares are typically available?

Common accessories include multiple die sets (various sizes and profiles), spare batteries, chargers, carrying cases, hydraulic oil, seals/O-rings, and service kits. Check the accessory list from the manufacturer or your supplier for exact part numbers.

14. How should I store and transport the EZ-300?

Remove the battery for long-term storage, keep the tool in a dry, dust-free case, and store within the recommended temperature range. Secure dies and accessories to prevent damage during transport. Follow any specific storage instructions in the user manual.

15. How do I obtain service, spare parts, or warranty support?

Contact the manufacturer or your authorized distributor with the tool model and serial number. They can provide spare parts, replacement dies, maintenance services, and warranty support. Refer to the warranty documentation for terms, coverage period, and required proof of purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals