B21, China Town Mall, Midrand

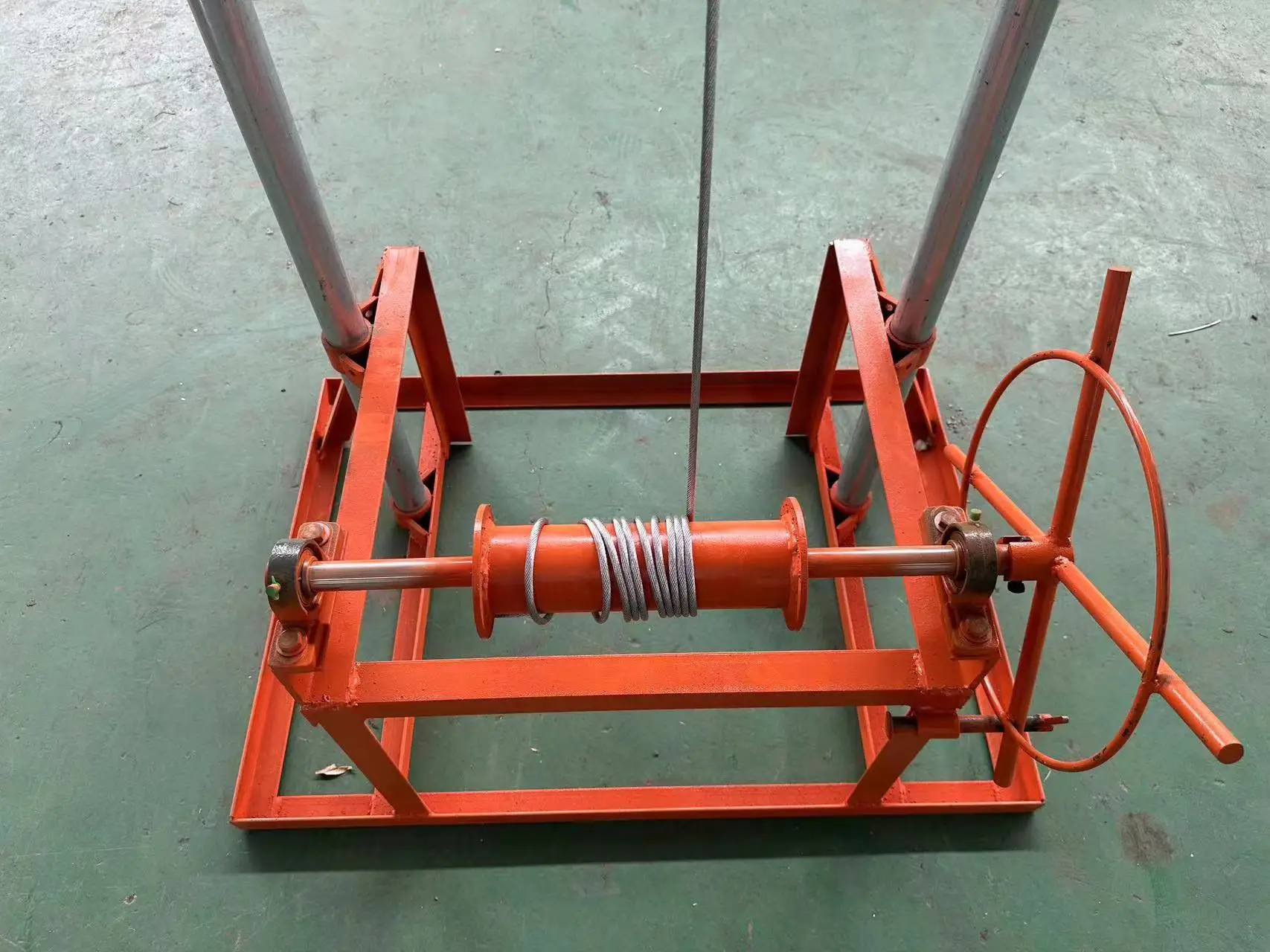

Earlybird Mini Core Drilling Rig for Water Wells

- Section : Machinery

- Category : Mining Machinery

- SKU : 1600951766331

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What drilling diameter and maximum depth can the Earlybird Mini Core Drilling Rig achieve?

The rig is designed to drill hole diameters from 80 mm to 220 mm with a maximum practical drilling depth of up to 80 meters (depending on soil/rock conditions and tooling).

2. What power options are available for this rig?

Multiple power options are offered: diesel and gasoline engines are standard, and the rig can also be configured for single-phase or three-phase electric power. Some configurations support hydraulic power as well.

3. What are the rig's dimensions and weight? Is it truly portable?

There are compact mini configurations and a larger EB-200 configuration. The mini dimensions are approximately 1730 × 860 × 1360 mm with a gross weight around 300 kg. The EB-200 variant measures about 1900 × 1100 × 2600 mm and weighs about 620 kg (highest point up to ~2.7 m). The mini version is lightweight and portable for transport on small trailers or vehicles; larger variants require heavier transport.

4. Which drilling methods and tasks can this rig perform?

The machine supports core/rotary drilling, impact rotary (where applicable), auger drilling, pipe casing installation, and sample (cylinder) extraction. It can also perform water-flushing drilling with positive and negative circulation suitable for many water-well and basic geological surveying tasks.

5. What accessories and standard components come with the rig?

Typical components include the engine (diesel/gasoline/electric), winch for lifting drill strings, gearbox, drill pipes (commonly 1.5 m lengths), and a centrifugal pump (4-inch on some configurations). Specific inclusions vary by package—confirm exact accessories with the supplier.

6. How easy is it to operate the Earlybird Mini Core Drilling Rig?

The rig is designed for user-friendly operation with simple controls, making it suitable for operators with limited experience. Basic training is recommended to ensure safe and efficient use.

7. Can the rig be used in remote or indoor locations?

Yes. Its compact footprint (less than 1 m² for the mini version) and controllable working height (about 2.6–2.7 m) allow use in confined or remote sites. Choose the power option (e.g., engine vs. electric) appropriate for site access and ventilation constraints.

8. What maintenance is required to keep the rig reliable?

Regular maintenance includes engine servicing, gearbox and winch inspections, lubrication of moving parts, checking drill pipes and connections for wear, pump and circulation system checks, and replacing worn bits and seals. Follow the manufacturer's maintenance schedule and use recommended lubricants and parts.

9. Is customization available to match specific project needs?

Yes. Customization options commonly include different power sources (engine/electric), extended drilling depth packages, alternate pump or winch options, mobility/transport solutions, and color or control-system preferences. Discuss your project requirements with the supplier for a tailored configuration.

10. What types of sites and projects is this rig best suited for?

It's ideal for small- to medium-scale water-well drilling for residential, agricultural, and small industrial uses, basic geological surveying, environmental sampling, and sites with limited access where a compact rig is advantageous.

11. How does ground condition affect performance and what soils can it handle?

Performance and advance rates depend heavily on geology. The rig handles unconsolidated sediments, sands, gravels and many softer rocks well. Extremely hard rock or very abrasive formations may require specialized bits, impact/hammer systems, or a larger rig—consult the supplier with site geological details for suitability and tooling recommendations.

12. What safety features and precautions should operators follow?

Operators should use appropriate PPE (helmets, gloves, eye and hearing protection), ensure the rig base is stable and level, verify emergency-stop and control functions, ground electrical versions properly, and follow the operator manual for safe lifting and handling of drill rods. Only trained personnel should operate or maintain the machine.

13. Are spare parts and after-sales support available?

After-sales support and spare parts availability depend on the supplier/distributor. Most suppliers offer replacement parts (drill rods, bits, seals, belts) and technical support or training—confirm warranty terms, lead times and local parts support when ordering.

14. How quickly can the rig be set up and mobilized on site?

Setup time varies with configuration and crew experience. The compact mini version is designed for quick deployment and can typically be set up in a short period by a small crew. Larger variants (e.g., EB-200) will take longer and may require additional lifting or transport preparations.

15. How do I order the rig or get a site-specific quote and technical consultation?

Contact the supplier or dealer with your project details—desired drilling depth and diameter, ground conditions, preferred power source, access and transport constraints, and any customization needs. The supplier can provide quotations, configuration options, lead times, shipping, training and installation support.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading