B21, China Town Mall, Midrand

Dewatering Vibrating Screen Linear Motion-Mineral Separation

- Section : Machinery

- Category : Mining Machinery

- SKU : 1600541643147

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What industries is the Dewatering Vibrating Screen suitable for?

The Dewatering Vibrating Screen is widely used in industries such as beneficiation, coal preparation, building materials, metallurgy, and the chemical industry.

2. What are the main functions of the GNLMZ Series Dewatering Vibrating Screen?

The main functions include desliming, dewatering, demineralization, and dry discharge of tailings from iron ore, nonferrous metal ore, and coal.

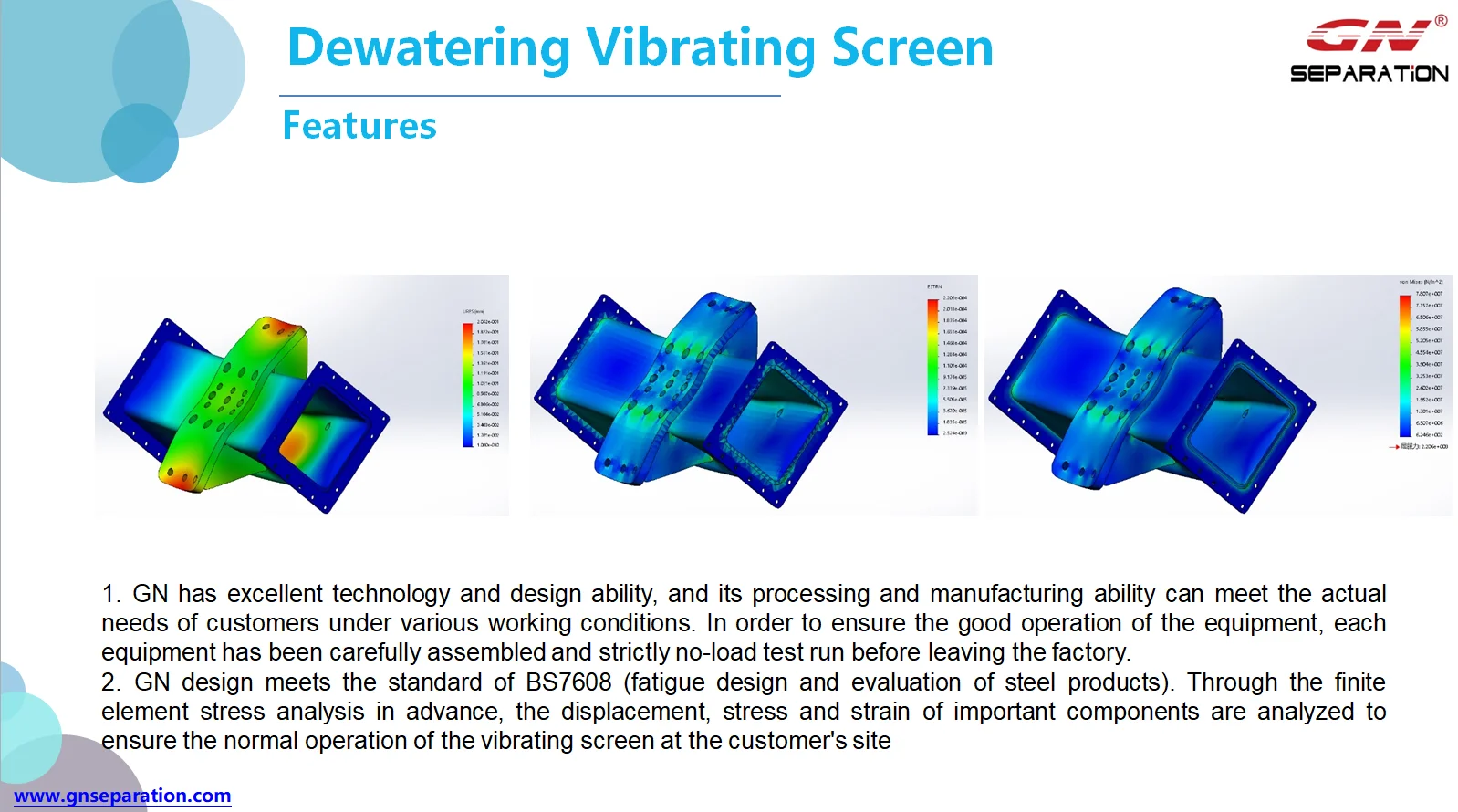

3. How does the design of the screen improve its performance?

The screen employs advanced finite element analysis and anti-fatigue analysis to optimize structural strength, reduce energy consumption, and enhance dewatering capacity.

4. Can the size of the Dewatering Vibrating Screen be customized?

Yes, the size of the machine can be customized according to customer requirements.

5. What materials are used in the construction of the screen?

The screen is constructed using high-quality steel plates selected for their impact toughness, and it features a hydraulic tension assembly using imported HUCK rivets.

6. What is the advantage of the wallboard design?

The wallboard is not welded, which eliminates residual stress and material defects, thus avoiding a reduction in fatigue strength.

7. How does the screen resist wear and corrosion?

Fluid touching parts and easily worn parts are sprayed with polyurea, which is resistant to corrosion, erosion, and wear.

8. What is the benefit of the post-weld heat treatment process?

The post-weld heat treatment process effectively eliminates welding stress in the main components, enhancing durability.

9. What features contribute to the screen's efficiency?

The screen offers large processing capacity, high efficiency, stable performance, and is designed to adapt to various working conditions.

10. How do I maintain the Dewatering Vibrating Screen?

Regular maintenance includes checking for wear on components, ensuring proper tensioning, and cleaning the screen to prevent clogging.

11. Is training provided for operating the Dewatering Vibrating Screen?

Yes, training can be provided upon request to ensure safe and efficient operation of the equipment.

12. What is the expected lifespan of the Dewatering Vibrating Screen?

With proper maintenance, the screen is designed to have a long service life, supported by features that reduce wear and fatigue.

13. Can the screen handle different types of materials?

Yes, the Dewatering Vibrating Screen can handle various materials including iron ore, nonferrous metals, and coal.

14. What is the typical installation process for the Dewatering Vibrating Screen?

Installation typically involves positioning the screen on a stable foundation, connecting it to the necessary power and water supply, and calibrating its settings.

15. Are replacement parts available for the Dewatering Vibrating Screen?

Yes, replacement parts, including modular polyurethane screen panels, are available and designed for easy replacement.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading