B21, China Town Mall, Midrand

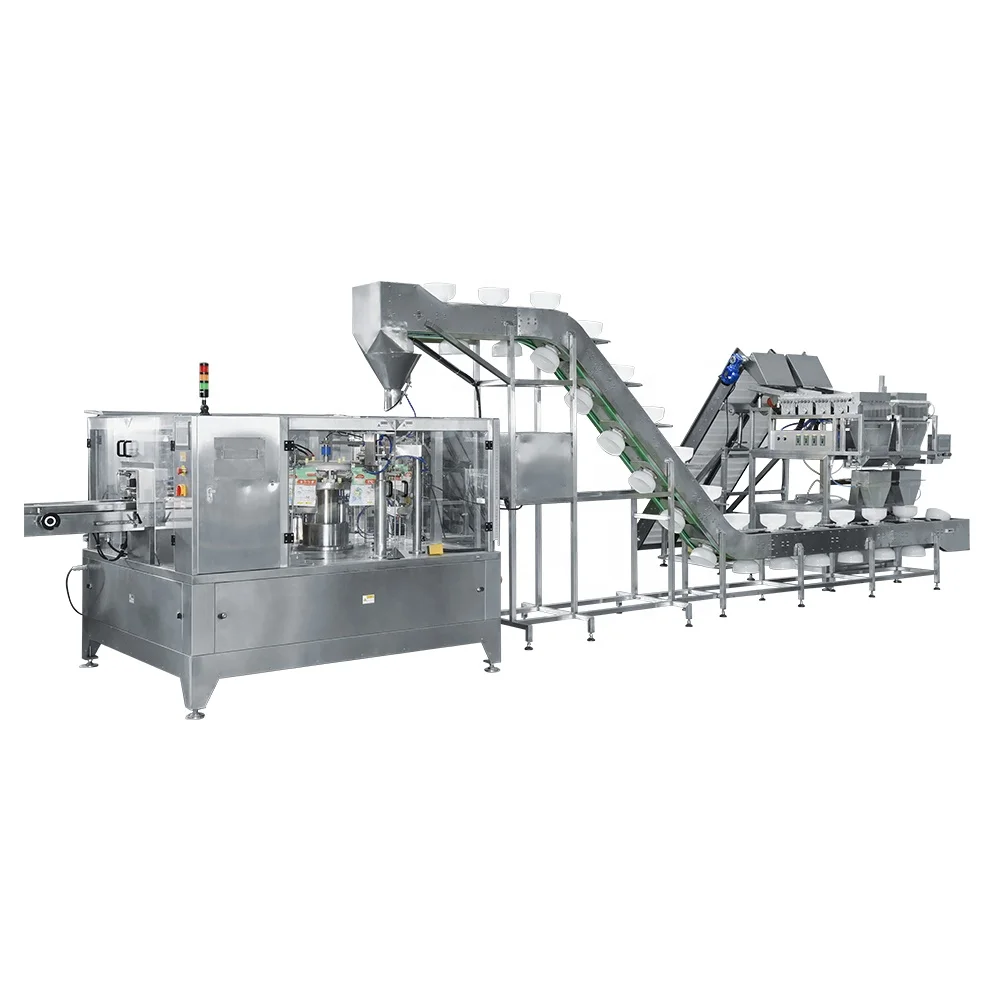

Dade High-Speed Washing Liquid and Laundry Detergent Pods Packaging Machine – Automatic, Efficient, and Accurate

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1601222780643

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of products can the Dade High-Speed Washing Liquid and Laundry Detergent Pods Packaging Machine package?

The machine is designed to package both laundry detergent pods and liquid packages, making it versatile for various chemical products.

2. What is the maximum speed of the packaging machine?

The Dade packaging machine can operate at a capacity of 350-700 pods per minute, depending on the size of the pods.

3. Is the machine fully automatic?

Yes, the Dade packaging machine operates fully automatically, reducing labor requirements and increasing production efficiency.

4. How accurate is the weighing and counting feature?

The machine is equipped with precise weighing and counting technology, achieving a filling precision of ±0.1ml and a sealing breakage rate of less than 1/1000.

5. What safety features does the machine have?

The Dade packaging machine is designed with a high safety level and ease of operation, making it user-friendly and safe for staff.

6. What materials are used in the construction of the machine?

The machine is constructed with high-quality materials including 316SS, 304SS, and oxidized hardened 6061 aluminum for durability.

7. What are the dimensions of the machine?

The dimensions of the Dade packaging machine are approximately L5100 x W1250 x H2950 mm.

8. Can the machine be monitored remotely?

Yes, the machine features remote control and monitoring capabilities, allowing you to oversee operations and make adjustments from a distance.

9. What kind of after-sales support is provided?

After-sales support includes video technical support, field installation, commissioning, training, online support, and field maintenance and repair service.

10. What is the power requirement for the machine?

The Dade packaging machine requires a power supply of 18Kw at 380V and 50Hz.

11. What is the required working temperature and humidity for optimal operation?

The optimal working temperature is around 25°C with a relative humidity between 40-50% RH.

12. How does the machine reduce waste during packaging?

The precise weighing and counting technology helps ensure accurate package sizes and pod counts, thereby reducing waste and improving consistency.

13. What is the weight of the machine?

The Dade packaging machine weighs approximately 2000 Kg.

14. What kind of filling pumps does the machine use?

The machine uses high precision ceramic piston pumps for accurate filling.

15. Can the machine accommodate custom capsule sizes?

Yes, the capsule sizes can be shaped and sized according to the customer's requirements.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals