B21, China Town Mall, Midrand

Color A1 Dual I1600 Heads 2400DP Wide Format White Ink Garment T-Shirt DTG Printer Printing Machine

- Section : Consumer Electronics

- Category : DTG Printers

- SKU : 1600912598576

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Color A1 TP-900D T-shirt Printer?

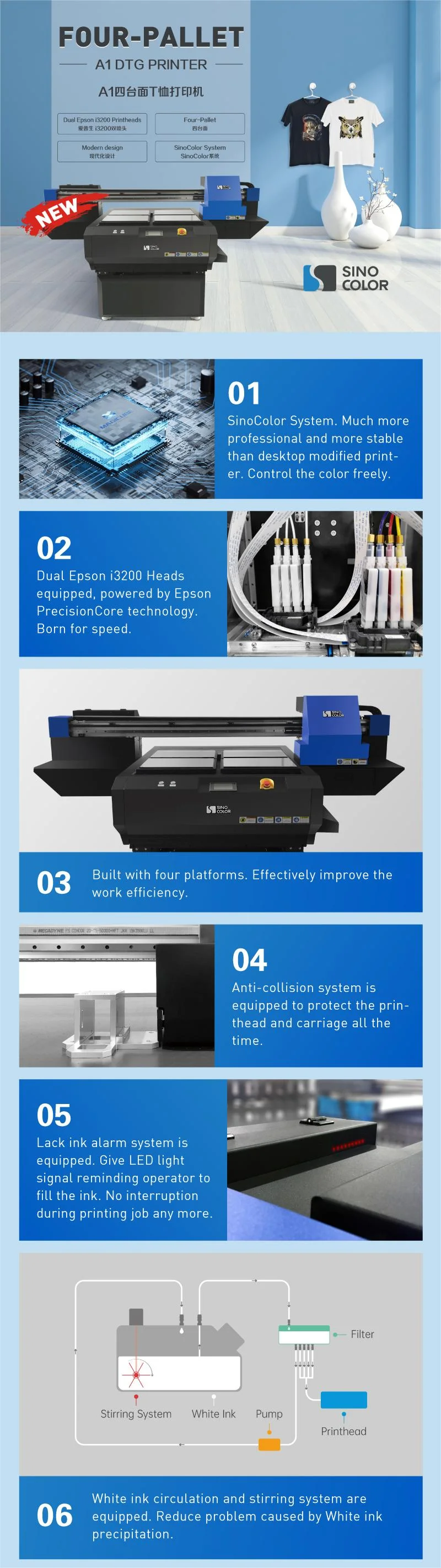

The TP-900D is a wide-format DTG garment printer built for high-quality, high-speed custom apparel printing. It ships with dual Epson i1600 printheads (optional i3200 upgrade), a CISS ink supply, and supports white-ink printing for dark garments.

2. What printheads and resolution does the printer use?

Standard configuration uses 2 x Epson i1600 printheads with an optional upgrade to i3200. It supports up to 2400 dpi for fine detail and vibrant color output.

3. How fast does the TP-900D print?

Typical print speed is around 1 minute per T-shirt. Actual throughput depends on design complexity, RIP settings, curing method and operator workflow.

4. What print area and pallet sizes does it support?

The TP-900D accommodates four 30 × 40 cm pallets, allowing multiple small prints or larger single graphics per run. Maximum garment thickness under the print head is 5 cm using the electric height adjustment.

5. Does this printer handle white ink for printing on dark garments?

Yes — the model supports white ink and uses a Continuous Ink Supply System (CISS) to maintain consistent white ink delivery required for dark or colored garments.

6. What is the ink consumption?

Ink consumption is economical at approximately 15–20 ml per square meter, though usage varies with coverage, RIP settings and print mode.

7. Which interface and software are supported?

The printer connects via USB 3.0. Standard RIP/software is Maintop; FlexiPrint is available as an optional RIP for more advanced color and production control.

8. What materials can I print on?

The TP-900D is designed for T-shirts and other garments — especially cotton and cotton-blend fabrics commonly used in DTG. For specialty fabrics or non-textile substrates, verify compatibility with the supplier.

9. Is garment pre-treatment required?

Pre-treatment is recommended for dark garments to ensure white-ink adhesion and print vibrancy. Use a compatible pre-treatment solution and follow best practices; contact your supplier for recommended products and application settings.

10. How do I cure prints after printing?

Curing must be done after printing (typically using a heat press or conveyor dryer) to set inks and achieve wash-fastness. Exact temperature and dwell time depend on inks and garments — consult your ink/pre-treatment supplier or vendor for recommended curing profiles.

11. What are the recommended operating conditions?

For optimal and consistent output, operate the TP-900D in a clean environment at 18–30°C and 30–70% relative humidity.

12. What are the physical dimensions and packaging size?

Machine dimensions are L2150 × W1350 × H1320 mm. Packed dimensions for shipment are L2240 × W1450 × H1070 mm.

13. What routine maintenance is required?

Regular maintenance includes printhead nozzle checks and cleanings, keeping the CISS clean and topped up, maintaining a dust-free environment, and periodic inspection of belts and mechanical components. Follow the manufacturer maintenance schedule for best results.

14. Does the TP-900D support double-sided printing?

Yes. The printer features an intelligent double-side print direction that enables printing on both the front and back of garments to increase productivity and expand design options.

15. What warranty, installation and training options are available?

Warranty terms, installation and training packages vary by seller and region. These details are not included in the product description — contact your vendor or reseller for available warranty coverage, onsite setup, and operator training services.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading