B21, China Town Mall, Midrand

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 03 Feb, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

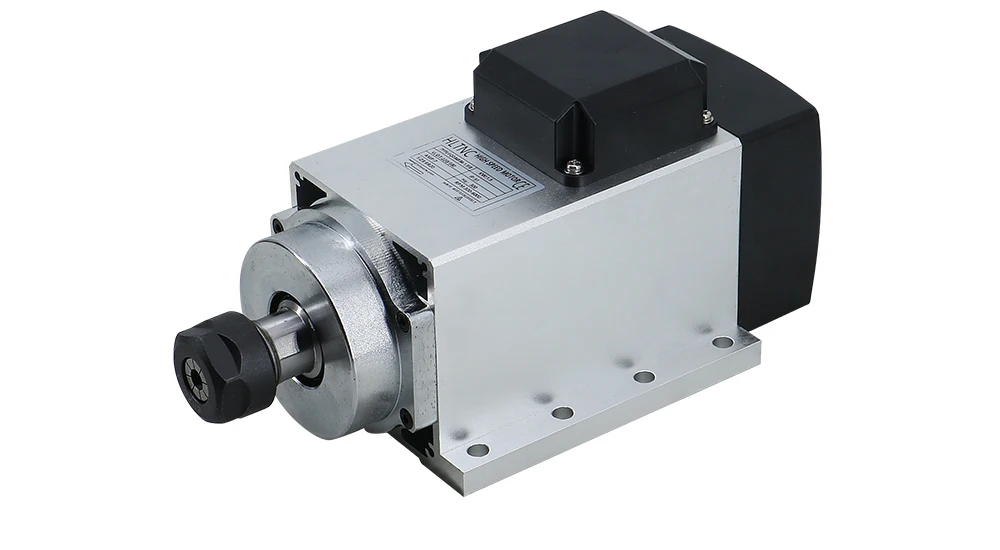

1. What is the power rating of the HLTNC CNC Mill Spindle?

The spindle is rated at 1.5 kW.

2. What type of cooling does this spindle use?

It uses an air cooling system — keep the airflow path clear for best performance and longevity.

3. How much does the spindle weigh and is it easy to install?

The spindle weighs 12 kg. Its relatively light weight makes it straightforward to install and handle in most workshop setups.

4. What collet and tool-holding hardware does it use?

The spindle uses ER20 collets for tool holding. The product description also indicates an ER11 nut is supplied on the spindle nose to help secure tooling — confirm exact included accessories with the supplier.

5. What spindle speeds (RPM) does it support?

The RPM range is not specified in the provided description. Please check the product datasheet or contact HLTNC/seller for the exact speed specifications.

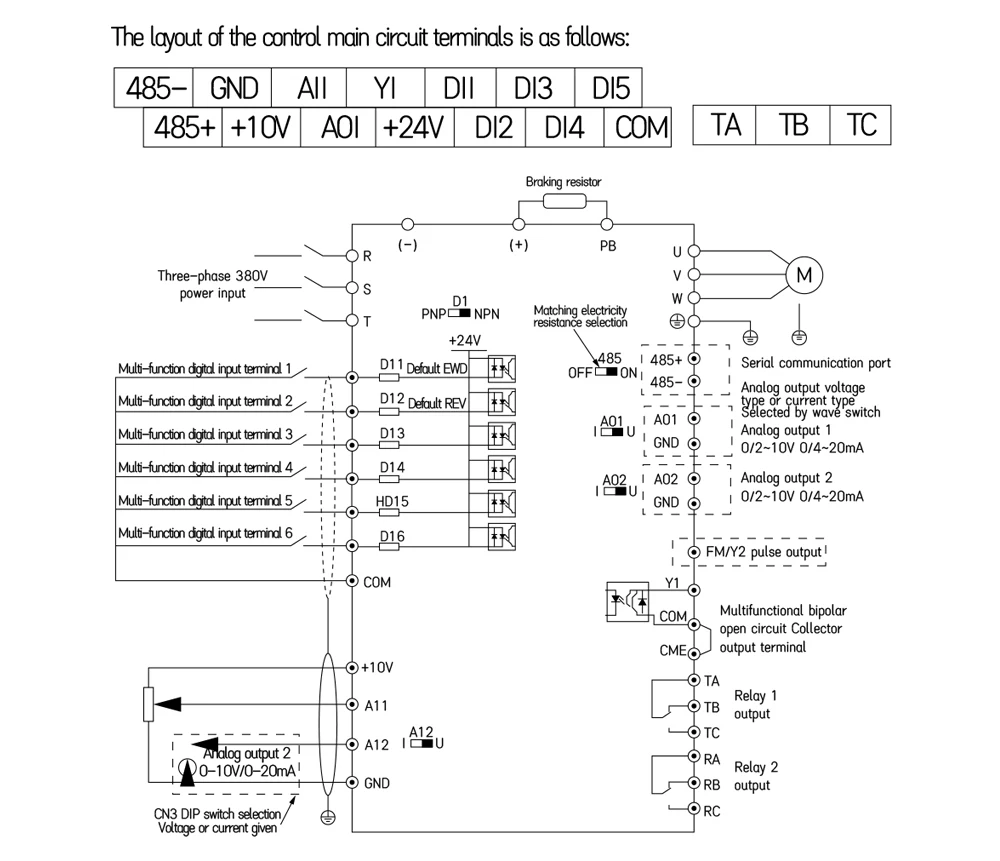

6. What drive or controller is required to run the spindle?

The description does not specify motor type or required drive. Most spindle motors require a compatible VFD or controller — confirm motor type, voltage, and control requirements with HLTNC or your supplier before installation.

7. Which materials can this 1.5 kW spindle mill effectively?

With 1.5 kW it is well suited for wood, plastics, composites and light metals such as aluminum. Heavy or hardened steels may require slower feeds, special tooling, or a higher-power spindle.

8. What maintenance does the HLTNC spindle require?

Regularly keep the cooling vents and exterior clean, inspect and replace collets and nuts as needed, check for play or noise in the bearings, and follow any maintenance schedule in the manufacturer's manual. Ensure the air-cooling path is not obstructed.

9. Are spare parts and accessories available (collets, nuts, bearings)?

ER20 collets and compatible accessories are commonly available. For original spare parts (bearings, nuts, etc.), contact HLTNC or your authorized dealer to ensure correct replacements.

10. Can this spindle be used for precision milling?

Yes — the spindle is described as having quality bearings and uses ER20 tooling, which supports precision milling tasks. Final accuracy will also depend on machine rigidity, proper installation, tooling balance, and setup.

11. Is the spindle suitable for continuous operation (duty cycle)?

The description does not list a duty cycle. Air-cooled spindles can often run for extended periods, but actual duty capability depends on load, speed, and cooling effectiveness. Verify duty cycle with HLTNC or the product datasheet.

12. What safety precautions should I follow when using the spindle?

Use appropriate PPE (eye and hearing protection), secure tools and workpieces, disconnect power before servicing, ensure proper ventilation/dust collection, and follow the manufacturer's safety and installation instructions.

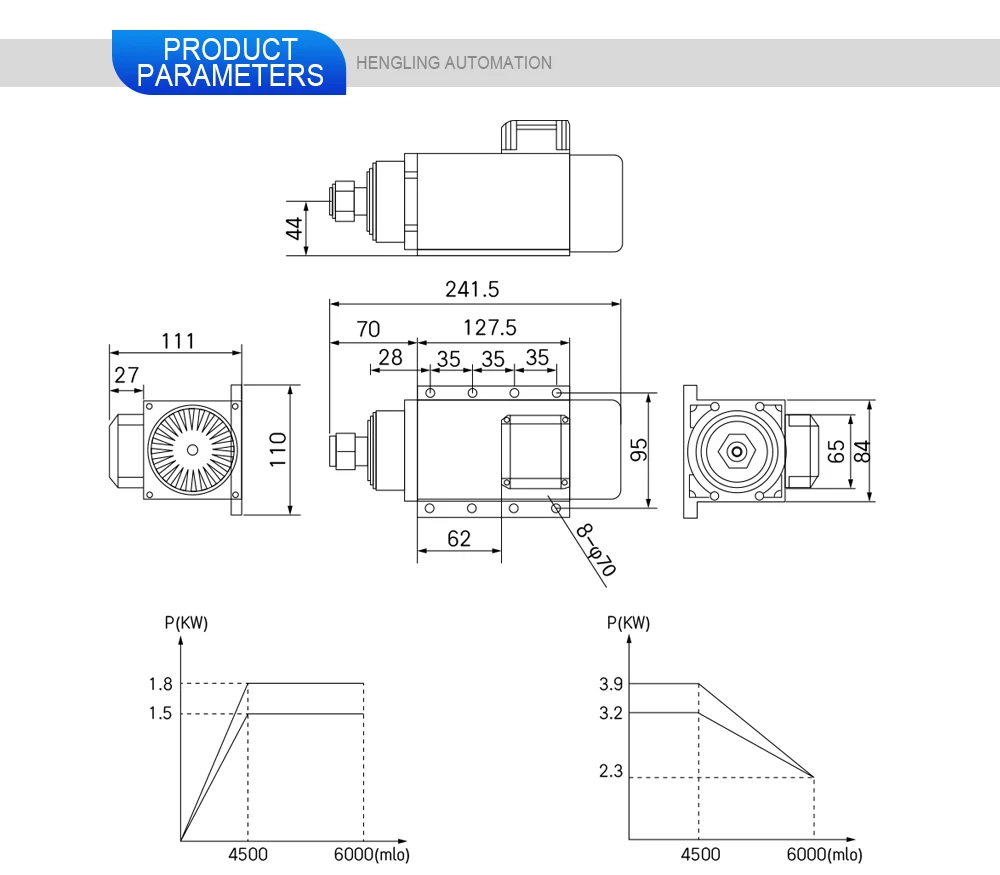

13. How do I know if this spindle will fit my CNC machine (mounting compatibility)?

Mounting compatibility depends on the spindle's flange or shaft dimensions and your machine's spindle mount. Because specific mounting dimensions aren't provided here, obtain the spindle's dimensional drawing or consult HLTNC/supplier and compare to your machine before purchasing.

14. What causes vibration or noise and how can I reduce it?

Common causes are unbalanced tooling, loose collets/nuts, worn bearings, or poor mounting. Use properly balanced cutters, tighten tooling to spec, ensure rigid mounting, and replace worn bearings to minimize vibration and noise.

15. What warranty and technical support are provided?

Warranty and support details are not included in the description. Contact HLTNC or the reseller to confirm warranty length, coverage, and available technical support before purchase.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals