B21, China Town Mall, Midrand

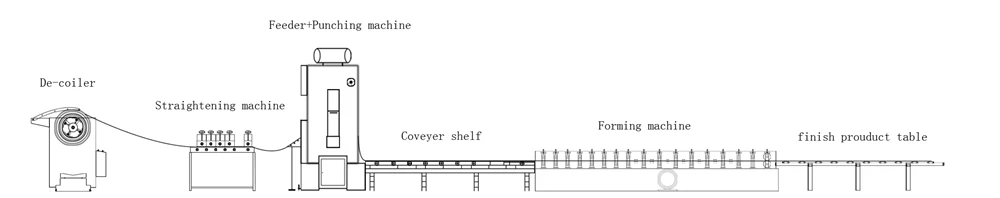

Cable tray roll forming machine with punching part

- Section : Machinery

- Category : Metal & Metallurgy Machinery

- SKU : 60674494158

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the main function of the cable tray roll forming machine with punching part?

The machine is designed to produce cable trays by combining a punching machine and a forming machine, allowing for efficient and precise manufacturing.

2. What materials can be used with this machine?

The machine can handle materials with a thickness of 0.6 to 2.0 mm, typically using metals suitable for cable tray construction.

3. What is the punching speed of the machine?

The punching machine has a punching speed of 120 to 180 times per minute, ensuring high productivity.

4. What is the power requirement for the punching machine?

The punching machine requires a rated power of 11 kW and operates on a voltage of 380V at 50Hz.

5. How does the feeding system work?

The feeding system uses servo technology to ensure precise feeding with no errors, enhancing the accuracy of the punching and forming processes.

6. What is the forming speed of the cable tray roll forming machine?

The forming machine operates at a speed of 15 to 20 meters per minute, allowing for efficient production of cable trays.

7. What type of control system is used in this machine?

The machine is equipped with a PLC control system, specifically from the Delta brand, providing reliable and user-friendly operation.

8. What is the total power requirement for the forming machine?

The forming machine requires a total power of 15 kW and operates on a voltage of 380V at 50Hz.

9. What materials are used for the rollers and shafts in the forming machine?

The rollers are made from GCr12 mov material, while the shafts are constructed from 45# steel, ensuring durability and longevity.

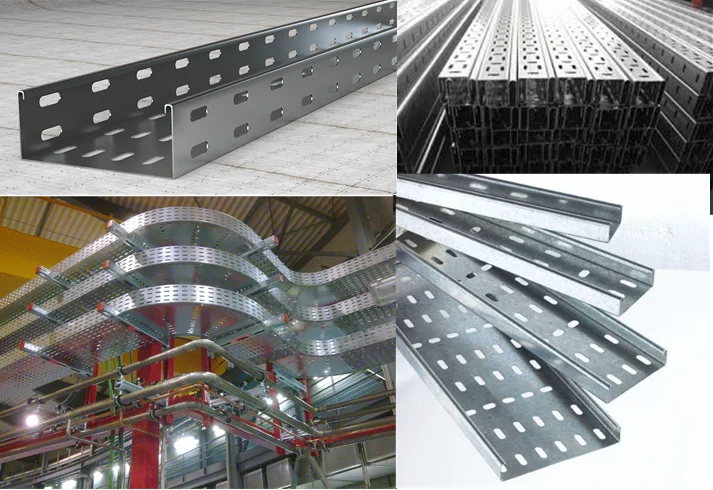

10. Can the machine produce different types of cable trays?

Yes, the machine can be adjusted to produce various designs of cable trays based on customer specifications.

11. Is support available if I have questions about the machine?

Yes, you can contact us via email at machine(@)lnmachine.com, or reach out through WhatsApp at +86 18231196151 or Skype at haoxu-machinary for assistance.

12. What is the rated voltage for the machine?

The machine operates at a rated voltage of 380V with a frequency of 50Hz and is designed for three-phase power supply.

13. What safety features does the machine have?

The machine is designed with various safety features, including emergency stop buttons and protective covers to ensure operator safety during operation.

14. How do I maintain the cable tray roll forming machine?

Regular maintenance involves checking the lubrication of moving parts, ensuring electrical connections are secure, and cleaning the machine to prevent debris buildup.

15. What kind of training is provided for new users of the machine?

We provide comprehensive training for new users, covering operation, maintenance, and troubleshooting to ensure efficient use of the machine.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading