B21, China Town Mall, Midrand

Automatic Tea Sugar Rice Salt Coffee Powder Detergent Powder Filling Packing Machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1600553809675

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is this machine used for?

This is an automatic multi-function filling and packing machine for powders and small granules — commonly used to pack tea, sugar, rice, salt, coffee powder, detergent powder and small hardware/components into sealed bags.

2. What models are available and how do they differ?

Three models are listed: GX-220DKF, GX-320DKF and GX-420DKF. They differ mainly in maximum roll film width, applicable bag size ranges, filling capacity ranges, physical dimensions, power rating and machine weight (GX-220DKF is the smallest/lightest; GX-420DKF supports the largest bags and heaviest fills).

3. What bag sizes and filling ranges can each model handle?

GX-220DKF: roll film up to 220 mm; bag length 10–150 mm; bag width 20–100 mm; filling range 1–99 g. GX-320DKF: roll film up to 320 mm; bag length 10–190 mm; bag width 60–150 mm; filling range 10–500 g. GX-420DKF: roll film up to 420 mm; bag length 10–260 mm; bag width 120–200 mm; filling range 100–1000 g.

4. Which film materials are compatible?

Compatible with a variety of heat-sealable films including plain plastic film, laminated film, aluminum-foil laminate, filter paper and certain non-woven fabrics — provided the film is heat-sealable and suitable for the bag former and sealing temperature.

5. How accurate is the filling and how is weight controlled?

Filling is controlled by an intelligent microcomputer controller and the machine's metering dispenser. Weight settings can be adjusted directly on the display interface. Accuracy depends on the product characteristics and calibration, and the double-vibration device improves consistency for most powders.

6. What is the double vibration device and why is it important?

The double vibration device agitates and densifies powder or granular products during filling to ensure smooth, uniform flow and consistent pack weights. It reduces bridging and uneven fills for many powder types.

7. What are the machine's power requirements?

The machine supports 220V/110V at 50Hz/60Hz. GX-220DKF is rated at 550W, GX-320DKF at 600W. For GX-420DKF please confirm exact power rating with the supplier as it may vary with configuration.

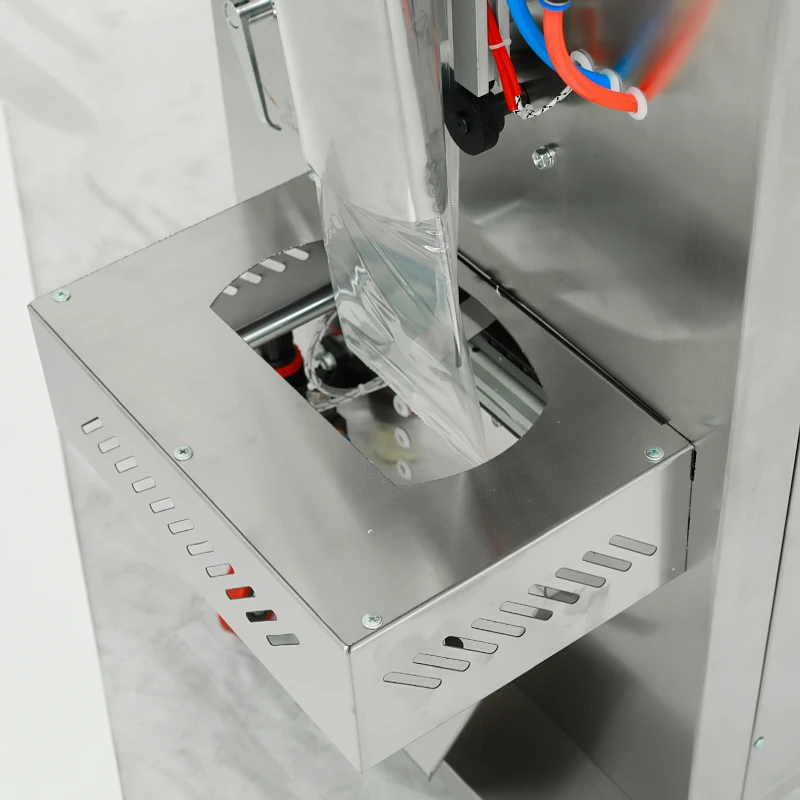

8. What is the construction material and is it food safe?

The machine is constructed from food-grade stainless steel (304), which ensures hygiene, corrosion resistance and compliance with common food-contact requirements.

9. Is the machine mobile and easy to move?

Yes — it is equipped with universal wheels for easy movement around a workspace. Ensure wheels are locked during operation for stability.

10. What optional devices are available?

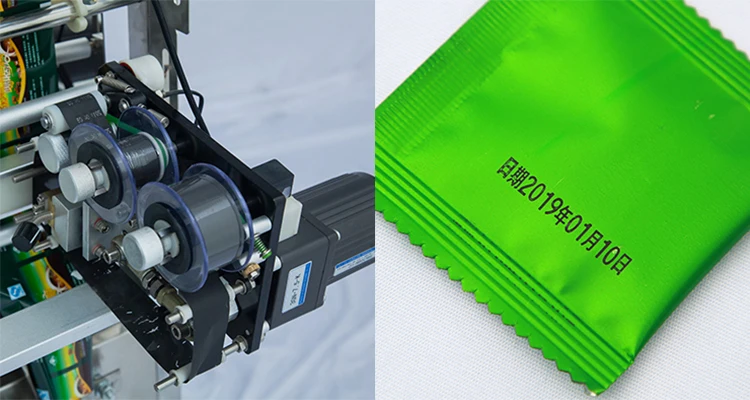

Optional devices include a photoelectric eye for high-precision color-mark tracking (accurate bag cutting), a date/printer for expiration/batch/manufacture dates, and additional metering devices or custom modules — options depend on model and supplier.

11. How do I change bag sizes and how long does changeover take?

Bag size changes require selecting new bag length/width settings on the controller and installing the appropriately sized bag former. Changeover time depends on operator skill and model but is typically short — consult the supplier for step-by-step guidance and recommended spare formers to speed changeovers.

12. How do I clean and maintain the machine?

Because it is stainless steel, wipe down food-contact surfaces regularly, remove and clean hoppers and bag former as needed, check and lubricate moving parts per the manual, inspect sealing blades and vibration components, and replace worn parts promptly. Follow the manufacturer's maintenance schedule for best performance.

13. Can it pack wet or sticky powders?

The machine is optimized for dry powders and granules. Very wet or highly sticky materials may cause bridging, poor sealing or frequent blockages. For challenging materials, consult the supplier about special feeders, anti-stick coatings or additional agitation options.

14. Do you provide installation, training and after-sales service?

Installation, commissioning and operator training are commonly offered by suppliers or distributors. After-sales service, spare parts and warranty terms vary — contact the seller for specific service packages, lead times and warranty coverage.

15. How do I ensure precise cutting and seal quality?

The machine uses independent PID temperature control for sealing and precision cutting blades. Proper film selection, correct temperature settings, regular blade maintenance and optional photoelectric mark tracking will ensure neat back-seals and accurate cuts.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals