B21, China Town Mall, Midrand

Automatic Electric Data Wire Power Cable Coiling Winding And Tying Binding Banding Machine

- Section : Machinery

- Category : Machine Tool Equipment

- SKU : 1600882368810

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

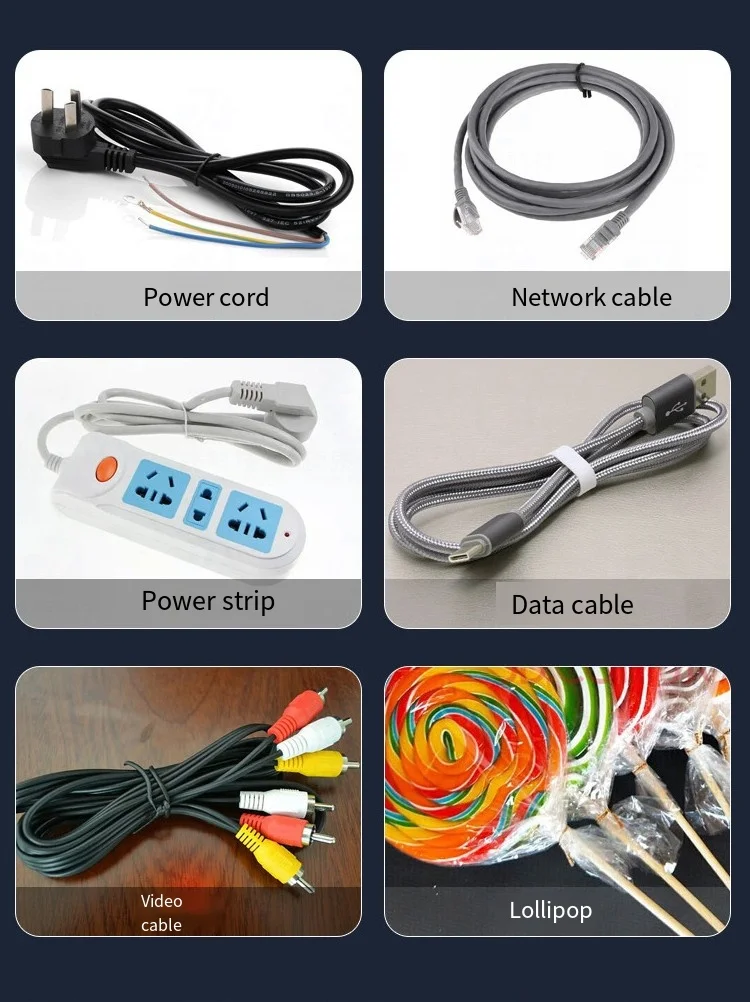

1. What types of cables can the Automatic Electric Data Wire Power Cable Coiling Winding and Tying Binding Machine handle?

The machine is suitable for various cable types, specifically designed for bundle diameters ranging from 40mm to 80mm.

2. How does the PLC control improve the machine's efficiency?

The PLC control automates the winding and binding processes, allowing for minimal manual intervention, which significantly speeds up operations and reduces labor costs.

3. What is the maximum tie length that can be set on this machine?

The machine can accommodate a cable tie length range of 200mm to 300mm, allowing for customization based on specific needs.

4. Is the machine noisy during operation?

No, the machine is designed for low noise operation, making it suitable for environments where noise sensitivity is a concern.

5. What is the winding speed of the machine?

The winding speed of the machine is adjustable, ranging from 1 to 13 laps per second, which enhances productivity.

6. Can the machine function solely as a winding machine?

Yes, the machine is versatile and can operate solely for winding or binding tasks independently.

7. What are the dimensions of the machine?

The dimensions of the machine without the cable tie bracket are 550mm x 610mm x 420mm.

8. How much power does the machine consume?

The rated power consumption of the machine is less than 300W, making it energy efficient.

9. Is there a specific voltage requirement for this machine?

The standard input voltage is AC220V at 50HZ/60HZ, but special voltage configurations can be customized upon request.

10. What is the weight of the machine?

The machine weighs 40KG, making it relatively easy to position in your workspace.

11. How much labor cost can I save by using this machine?

The machine can save 1-2 labor costs by speeding up the winding and binding processes, thus reducing the workload on staff.

12. What kind of training is required to operate this machine?

The machine is designed for simple operation, which reduces training time for operators, allowing them to quickly become proficient.

13. What technology is used to ensure precision in winding?

The machine utilizes stepper motor technology, which ensures that the winding reel stops at a fixed point for precise operation.

14. How does the machine's design benefit space management?

Its compact structure minimizes the space required for operation, making it ideal for use in tight production environments.

15. Can I customize the coil and tie settings?

Yes, operators can easily set the number of coils, tie length, and coil count to meet specific requirements.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading