B21, China Town Mall, Midrand

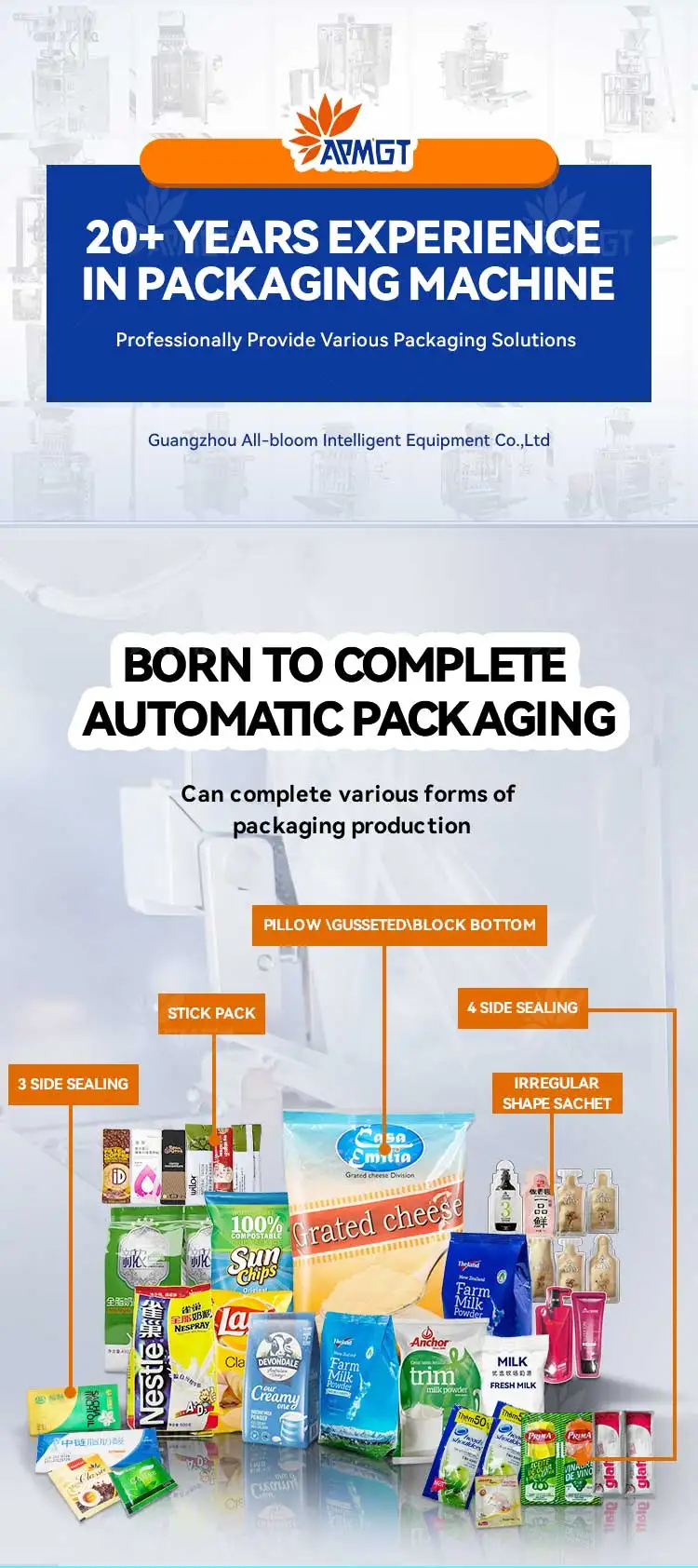

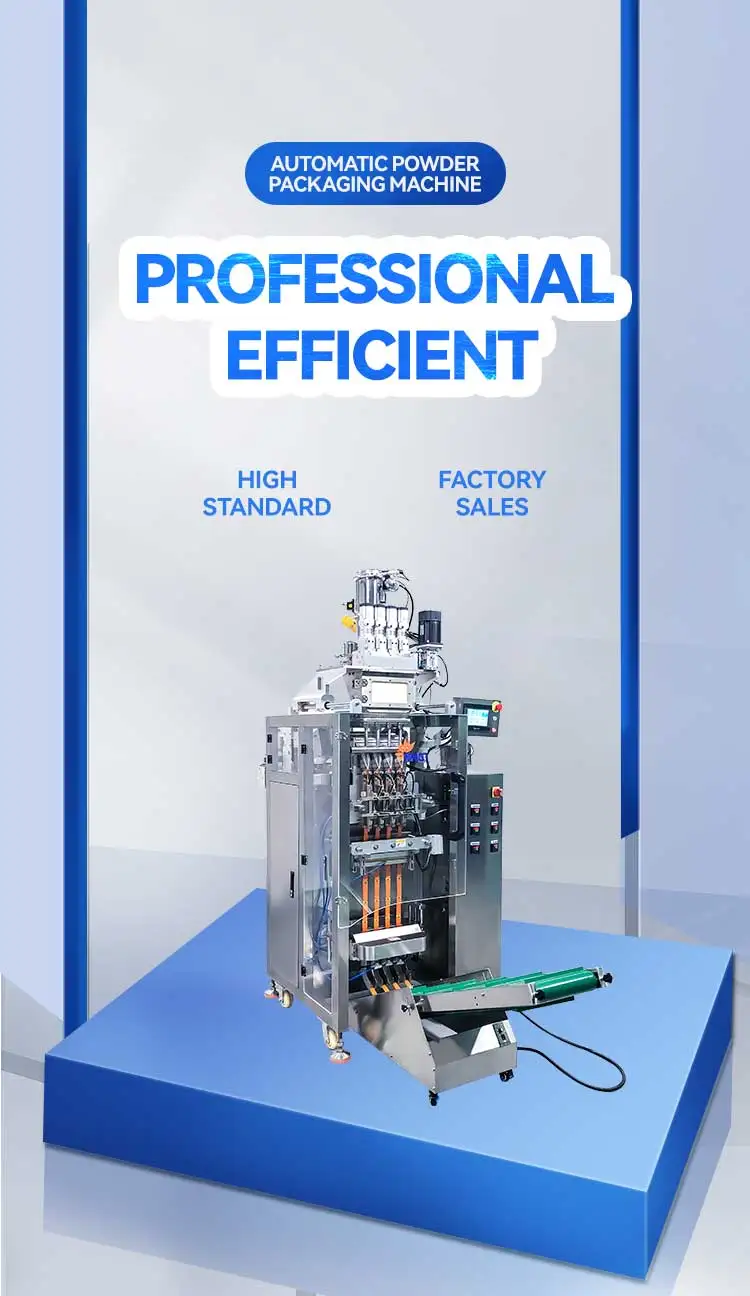

Automatic automatic stick chilli powder spice packaging machine

- Section : Machinery

- Category : Multi-Function Packaging Machines

- SKU : 1601026257189

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 21 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the model name and primary purpose of this machine?

The model is GH280BF. It is a multi-lane stick pack powder packaging machine designed for high-speed, precise packaging of powders (e.g., spices, coffee, sugar) into stick packs.

2. How many lanes does the machine support and why is that useful?

The machine supports 2–4 lanes, allowing higher throughput and better utilization of film for increased packaging efficiency and flexibility for different production volumes.

3. What is the maximum production speed (capacity)?

Maximum speed is up to 40 cycles per minute. Actual output depends on the number of lanes used, sachet size, product characteristics and film.

4. What sachet (stick pack) sizes can it produce?

Sachet length ranges from 50–180 mm and width from 20–65 mm. Pack sizes within those ranges can be produced with appropriate adjustments.

5. What film width and thickness does the machine accept?

Maximum film width is 280 mm and recommended film thickness is 0.07–0.10 mm. Use films compatible with back-seal stick packaging.

6. What filling methods are available for different powder types?

Three filling methods are offered: long auger, short auger, and short auger with cup. Choose based on powder flowability, particle size and dosing accuracy requirements.

7. What cutting and sealing options are available?

Sealing is back-sealing (stick bag). Cutting options include straight cutting, zig-zag cutting, round cutting and die-cut for customized pack edges.

8. What are the electrical and pneumatic requirements?

Electrical power requirement is 3.5 kW. Compressed air requirement is 0.8 MPa at approx. 0.8 m³/min. Verify supply compatibility before installation.

9. What are the machine dimensions and weight?

Typical dimensions are approximately 1385 × 918 × 2005 mm and the machine weight is around 350 kg. Confirm final dimensions for shipping and floor-space planning.

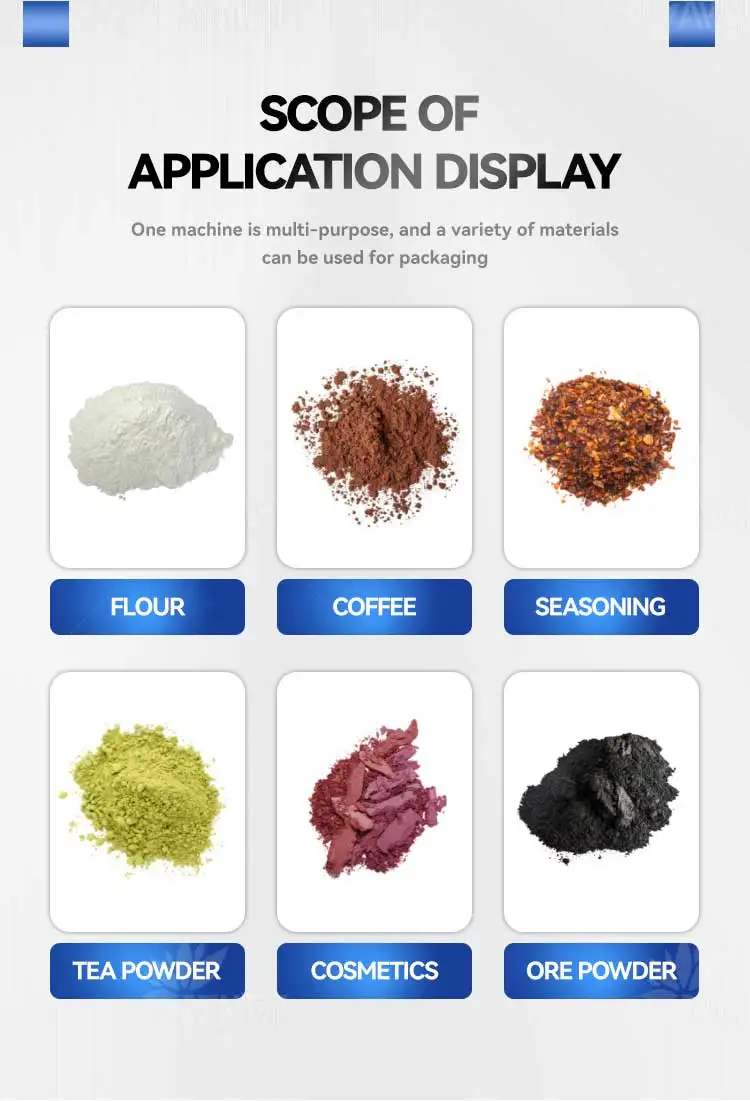

10. Which powders can this machine handle?

It is suitable for many free-flowing and semi-free-flowing powders such as spices, coffee, sugar, instant drink mixes and similar products. Very cohesive or highly hygroscopic powders may require product testing and specific auger choices.

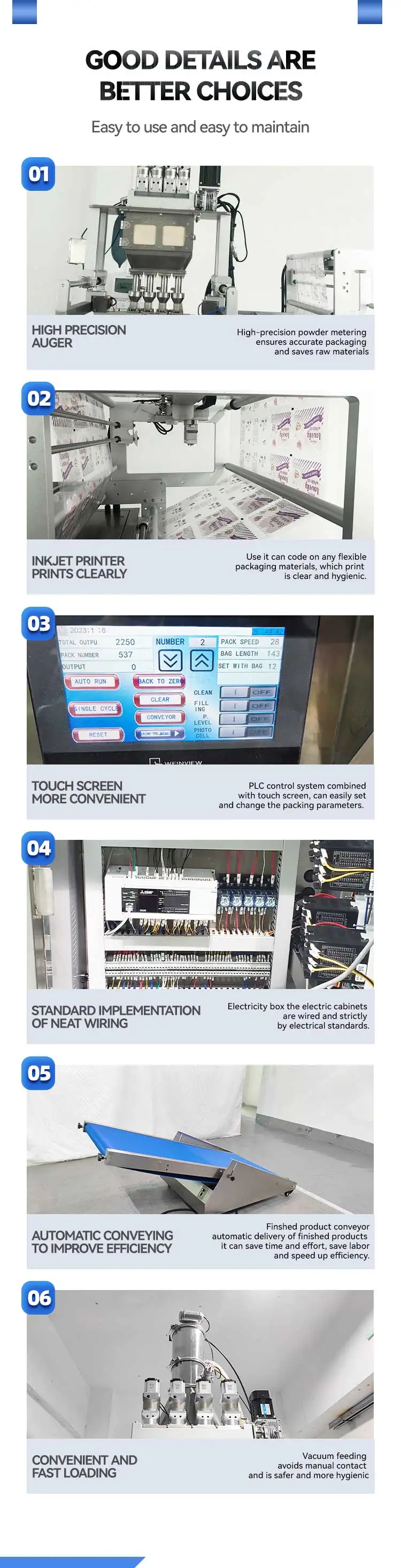

11. How easy is cleaning and maintenance?

The machine is designed for easy operation and maintenance with removable filling parts for cleaning. Routine maintenance includes cleaning augers, checking seals, lubrication and inspection of wear parts. Follow supplier maintenance guidelines.

12. How long does changeover between sachet sizes take?

Changeover time varies by operator experience and the difference between formats. Typical changeovers range from a few minutes to up to an hour. Quick-change design and clear instructions can reduce downtime.

13. Does the machine include safety features and operator controls?

The machine is designed with user-friendly controls and protective housings. Specific control options (e.g., PLC and touchscreen) and safety features (emergency stop, guards) are available—confirm exact configuration with the supplier.

14. Are spare parts, warranty and after-sales support available?

Spare parts and after-sales support are available—contact the supplier for details on parts availability, lead times, warranty terms and support packages including installation and training.

15. Can I get product testing, customization or factory acceptance?

Yes—suppliers typically offer sample testing with your powder and film, and can provide customization (e.g., lane count, cutting die) to meet your needs. Ask the supplier about factory acceptance testing (FAT) and on-site trials.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals