B21, China Town Mall, Midrand

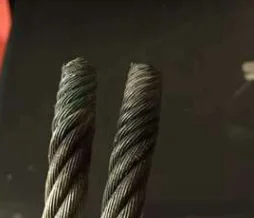

Automatic 6-32mm steel wire rope cutting annealing welding melting making machine

- Section : Machinery

- Category : Metal & Metallurgy Machinery

- SKU : 60821326799

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the maximum diameter of steel wire rope that this machine can cut?

The Automatic 6-32mm steel wire rope cutting machine can handle steel wire ropes with a diameter ranging from 6mm to 32mm.

2. What types of steel ropes can this machine melt?

This machine is suitable for melting various types of steel ropes, including elevator ropes, mine ropes, crane cables, and other high-quality steel ropes.

3. How does the annealing process work in this machine?

The machine utilizes high melting speed to effectively anneal the steel ropes, ensuring they have neat and smooth conical and spiral ends after the process.

4. Is the machine easy to operate?

Yes, the machine is designed to be easy to operate, and no spanner is needed for the tightening device, making it user-friendly.

5. What are the power options available for this machine?

The machine has different models with varying power options: CF16 (5 KW), CF32 (25 KW), CF40 (100 KW), and CF60 (100 KW).

6. What is the weight of the machine?

The weight of the machine varies by model: CF16 is 75 kg, CF32 is 260 kg, CF40 is 550 kg, and CF60 is 600 kg.

7. Can the machine melt ropes of different diameters without changing parts?

Yes, the machine has a wide melting diameter range and can melt steel ropes without replacing any parts within the prescribed diameter range.

8. What is the energy consumption of the machine?

The machine is designed to have low working power, making it energy-efficient and safe for use.

9. What are the dimensions of the machine?

The dimensions vary by model: CF16 is 700*400*1200 mm, CF32 is 700*800*1150 mm, CF40 is 1600*1200*1800 mm, and CF60 is 1600*1200*1800 mm.

10. Is the machine portable?

Yes, the machine has a clever design which makes it convenient to move around.

11. What safety features does the machine have?

The machine is designed to be safe in use, with energy-saving features and an easy operating mechanism to minimize risks.

12. Who typically uses this machine?

This machine is mainly used by steel rope manufacturers and customers looking to melt and anneal steel ropes efficiently.

13. How can I maintain the machine for optimal performance?

Regular maintenance includes cleaning the machine after use, checking for any wear and tear, and ensuring all components are functioning correctly.

14. What is the burn out range for each model?

The burn out range varies by model: CF16 has a range of 3-16 mm, CF32 is 6-32 mm, CF40 is 20-40 mm, and CF60 is 28-60 mm.

15. Can I get technical support for this machine?

Yes, technical support is typically available from the manufacturer or distributor for any issues or questions regarding the machine.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading