B21, China Town Mall, Midrand

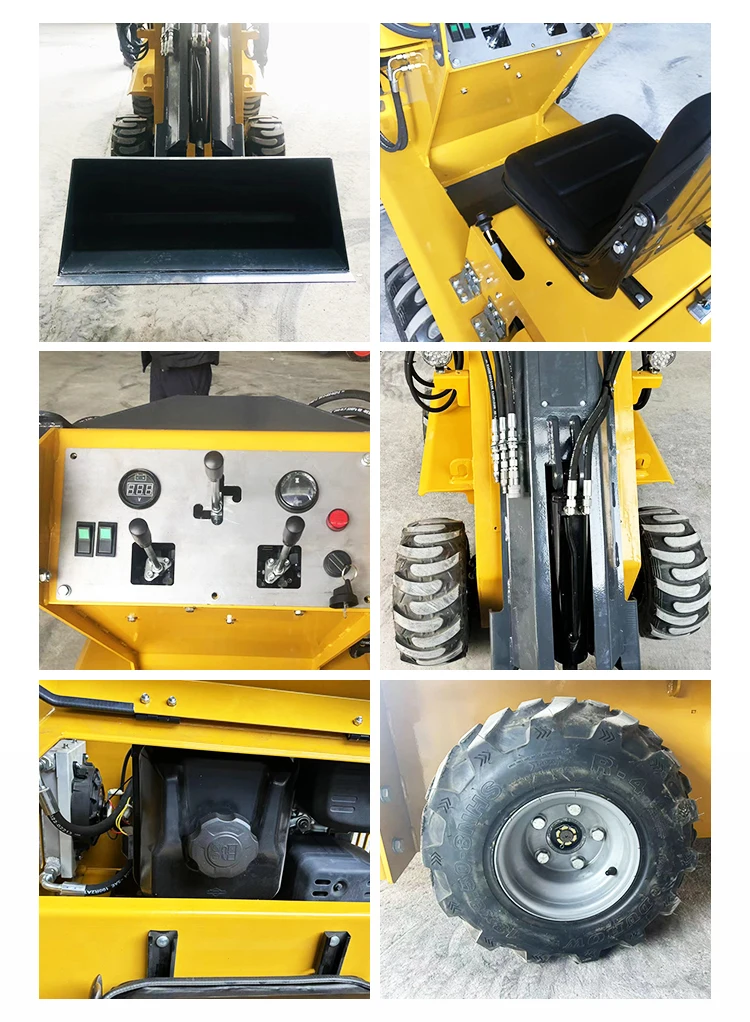

YXS-10 Hydraulic Mini Skid Steer Loader Earthmoving Machinery

- Section : Machinery

- Category : Engineering & Construction Machinery

- SKU : 1601052950205

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 05 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What engine does the YXS-10 Mini Skid Steer Loader use and what is its power output?

The YXS-10 is powered by a Perkins EPA-certified 3-cylinder diesel engine with a rated power of 18.4 kW.

2. What are the hydraulic components and specifications?

Key hydraulic components include an Italy Hansa pump, Italy Hydrocontrol valve and a US Eaton motor. The working system and driving system pressure is 250 bar with a flow rate of 45 L/min.

3. What is the rated loading capacity and machine weight?

The specification lists a rated loading capacity of 400 kg. The product description also references a loading capacity of 450 kg and machine weights of 1,330 kg and 1,580 kg in different sections — please confirm the exact model/option with the supplier, as differences can reflect optional equipment or variant configurations.

4. What are the machine dimensions I should know for transport and jobsite planning?

Important dimensions: operating height 2,695 mm; height to bucket hinge pin 2,160 mm; overall height 1,590 mm; overall length with general-purpose (GP) bucket 2,817 mm and without bucket 2,165 mm; wheelbase 1,150 mm; overall width 1,060 mm; ground clearance 220 mm; angle of departure 23°.

5. What attachments are compatible with the YXS-10?

The loader supports a range of common skid-steer attachments such as GP buckets, pallet forks, augers, trenchers, hydraulic breakers, grapples and sweepers. Attachment compatibility can depend on the quick-attach system and hydraulic flow/pressure — confirm specifics and available factory options with your dealer.

6. Is the YXS-10 EPA certified or compliant with emissions regulations?

Yes. The unit is equipped with a Perkins engine that carries EPA certification as stated in the product details.

7. What kind of jobs and working environments is the YXS-10 best suited for?

The YXS-10 is suitable for earthmoving, landscaping, light construction, agriculture and municipal work where a compact, maneuverable loader is required. Its small footprint is ideal for confined spaces and tight jobsite conditions.

8. What are the recommended daily checks and basic maintenance tasks?

Perform daily inspections of engine oil level, coolant, hydraulic oil level, fuel, air filter, visible hydraulic lines and fittings for leaks, tire/track condition, and safety devices. Grease pivot points and check attachment pins before operation. Refer to the operator manual for service intervals and detailed procedures.

9. What should I know about hydraulic oil and service intervals?

The YXS-10 operates at 250 bar with a 45 L/min flow. Use hydraulic oil meeting the specifications in the operator manual and change/filter according to the recommended service intervals. For precise oil type and intervals, follow the manufacturer's service manual or contact your dealer.

10. How do I transport the YXS-10 safely?

Use a trailer or truck bed rated above the machine's transport weight (confirm model weight with supplier). Secure the machine using appropriate tie-downs at designated lift/tie points, lower the loader arms and lock attachments. Check local transport regulations for width/height limits.

11. What safety features and operator protections are included?

Standard compact skid-steers typically include operator presence controls, rollover protection structure (ROPS), seat belt or restraint system, and hydraulic lockouts. Verify the exact safety features and optional cab/ROPS/FOPS packages available from your dealer.

12. Can the YXS-10 be customized or ordered with optional packages?

Yes—manufacturers commonly offer optional attachments, auxiliary hydraulics, different tires/tracks, cab or canopy options, lighting packages and other accessories. Contact your supplier to review available factory or dealer options for the YXS-10.

13. Where can I get replacement parts and service for hydraulic components like the pump, valve and motor?

Replacement parts for the hydraulic pump (Italy Hansa), valve (Italy Hydrocontrol) and motor (US Eaton) are typically available through the OEM dealer network or authorized parts distributors. Provide the machine serial number and part numbers to ensure correct components.

14. What fuel should I use and what is fuel economy like?

Use diesel fuel that meets local quality standards and the engine manufacturer's recommendations. Fuel consumption varies with load, attachment and work cycle; for planning, consult your dealer for typical fuel usage figures based on expected duties.

15. What warranty and after-sales support options are available?

Warranty terms and after-sales support vary by manufacturer, region and dealer. Contact the selling dealer or OEM directly to get details on warranty coverage, service contracts, spare-parts availability and authorized service centers for the YXS-10.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading