B21, China Town Mall, Midrand

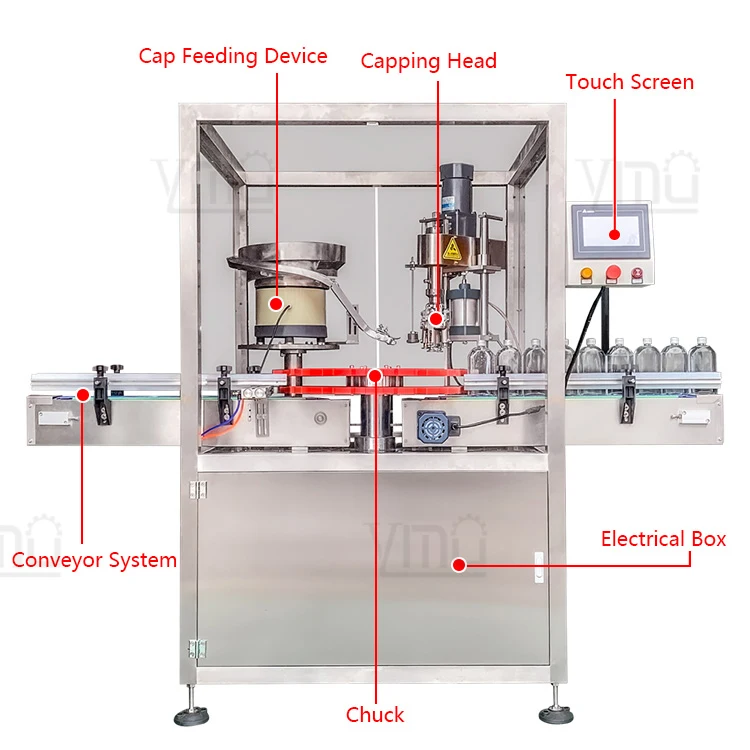

YIMU CM100 Automatic Oil whiskey Wine Bottle Ropp capper Aluminum cap Locking sealing Crimping Capping Machine for Metal Cap

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1600848629921

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What types of bottles can the CM100 capping machine handle?

The CM100 is suitable for glass bottles, aluminum caps, and various container sizes including wine bottles, olive oil bottles, syrup bottles, and whiskey bottles.

2. What is the capping success rate of the CM100?

The CM100 achieves a capping success rate of over 99.99%, ensuring minimal waste and maximizing production efficiency.

3. How fast can the CM100 machine operate?

The CM100 can handle between 1000 to 2500 bottles per hour, depending on the specific application and settings.

4. Is the CM100 machine easy to integrate into existing production lines?

Yes, the CM100 can be easily connected to other machines and conveyors for automated line operation, improving workflow efficiency.

5. What is the power supply requirement for the CM100?

The CM100 operates on a power supply of 1500W, 110V/220V, 50/60Hz, single phase, and it can be customized to meet specific needs.

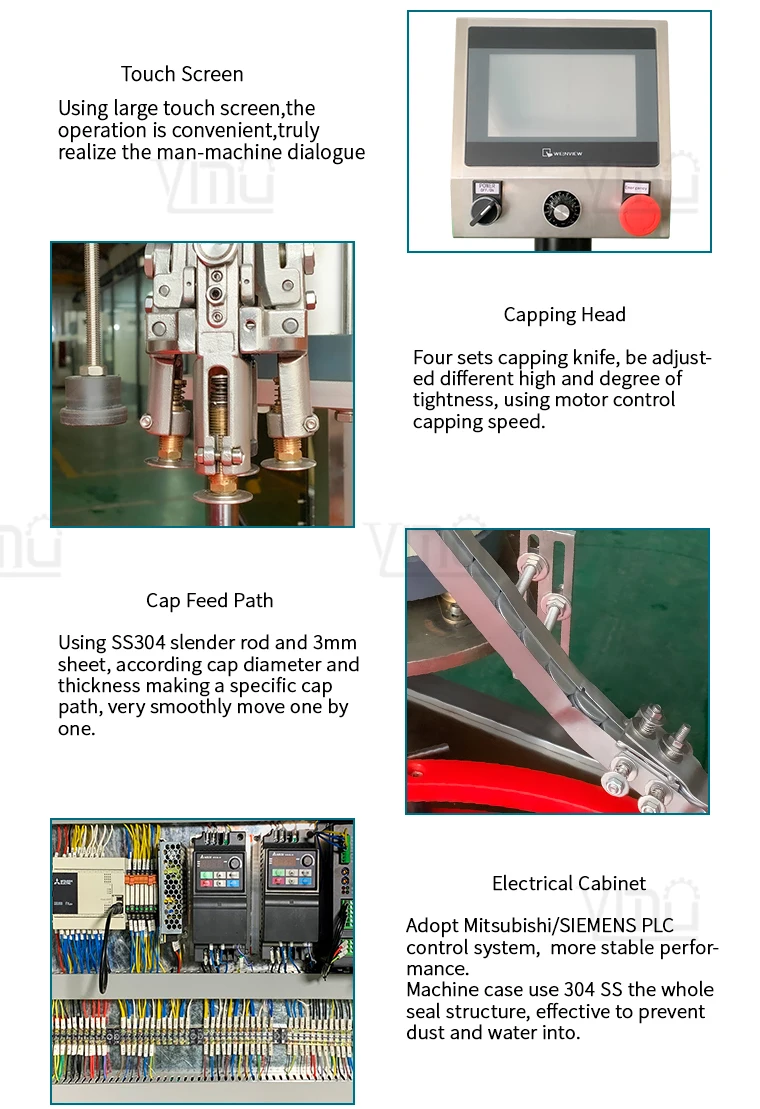

6. Can the capping head be adjusted for different cap sizes?

Yes, the capping head is easily adjustable to handle different cap sizes with precise torque control provided by a servo motor.

7. What kind of control system does the CM100 use?

The CM100 features a user-friendly Siemens HMI and Siemens or Mitsubishi PLC for easy operation and monitoring.

8. What is the size and weight of the CM100 machine?

The machine dimensions are L2000 × W1000 × H2000 mm, and it has a net weight of 500KG.

9. What materials are used in the construction of the CM100?

The CM100 is constructed with high-quality components, including a servo motor from China Raynen and sensors from SICK, KEYENCE, or Panasonic.

10. Does the CM100 require a specific type of cap feeding device?

The CM100 offers optional cap feeding devices, including a cap elevator or vibrating disk, depending on your production needs.

11. What industries is the CM100 suitable for?

The CM100 is ideal for various industries, including food and beverage, cosmetics, and pharmaceuticals, where precise and reliable cap sealing is critical.

12. Is the CM100 machine suitable for high-volume bottling?

Yes, the CM100 is designed for high-speed capping and is perfect for high-volume bottling lines.

13. What kind of maintenance does the CM100 require?

Regular maintenance includes checking the servo motor, ensuring the cap feeding system is functioning properly, and cleaning the machine to maintain optimal performance.

14. Can the CM100 be customized to fit specific production needs?

Yes, the CM100 can be customized in terms of power supply, cap feeding devices, and capping head adjustments to meet various production requirements.

15. What support is available for troubleshooting the CM100?

Technical support is available through the manufacturer, including guidance for troubleshooting and maintenance to ensure optimal operation.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading