B21, China Town Mall, Midrand

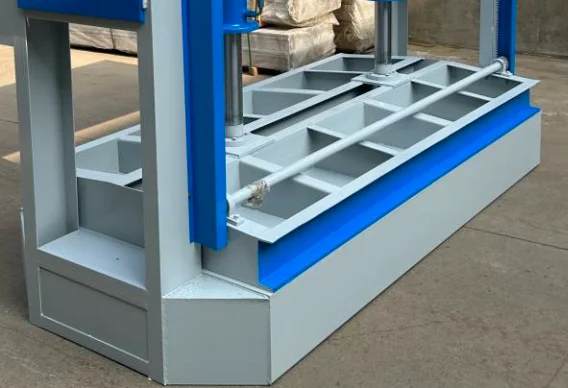

Woodworking Cold Press Machine MDF Melamine Machine Hydraulic Press Veneer Cold Press Machine

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1601161270112

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What materials can the woodworking cold press machine handle?

The woodworking cold press machine is designed to handle MDF, melamine, and veneer materials effectively.

2. What is the maximum pressure capacity of the hydraulic press?

The hydraulic press has a maximum pressure capacity of 50 tons.

3. What is the purpose of the timing control feature?

The timing control feature allows you to set a specific time for the pressing process. Once the time is reached, the pressure plate will automatically release and beep to notify the operator.

4. What are the dimensions of the machine?

The dimensions vary by model, with options such as 2910x1250mm for a 1.25-meter stroke and 3410x1250mm for a 1.25-meter stroke, respectively.

5. How does the machine ensure even pressure distribution?

The machine features a precision platen working table that ensures even pressure distribution across the entire table surface, helping to maintain flatness during pressing.

6. What is the installed power requirement for the machine?

The installed power requirement for all models of the machine is 4KW.

7. Is the cold press machine easy to operate?

Yes, the machine is equipped with an easy-to-use control panel that simplifies operation for users.

8. What is the weight of the machine?

The net weight of the machine varies by model, ranging from 1.8 tons to 2.4 tons.

9. What type of steel is used in the machine's construction?

The fuselage is made from national standard channel steel, ensuring stability and enhancing the machine's service life.

10. Can I customize the platen size?

The machine comes with specific platen sizes, such as 1250x2500mm, and customization options may vary. Please contact the manufacturer for more details.

11. How long does it take to press materials with this machine?

The pressing time can be set according to the material and desired outcome, using the timing control feature.

12. Is maintenance required for the hydraulic press?

Regular maintenance is recommended to ensure optimal performance and longevity of the hydraulic press.

13. What safety features does the machine have?

The machine incorporates several safety features, including an automatic release mechanism and an alert beep when the pressing cycle is complete.

14. Where can I purchase this woodworking cold press machine?

You can purchase the woodworking cold press machine from authorized dealers or directly from the manufacturer's website.

15. What is the warranty period for the machine?

The warranty period may vary; please check with the manufacturer or seller for specific warranty details.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading