B21, China Town Mall, Midrand

Winding Wire Machine CLH300 by CHENLI

- Section : Machinery

- Category : Industrial Machinery

- SKU : 1601026915590

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 31 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the CHENLI Winding Wire Machine CLH300 used for?

The CLH300 is designed for the cable making industry and is primarily used for winding and processing wires — especially PVC-insulated wire. It's a multifunctional machine aimed at improving efficiency and consistency in wire production.

2. What are the main technical specifications of the CLH300?

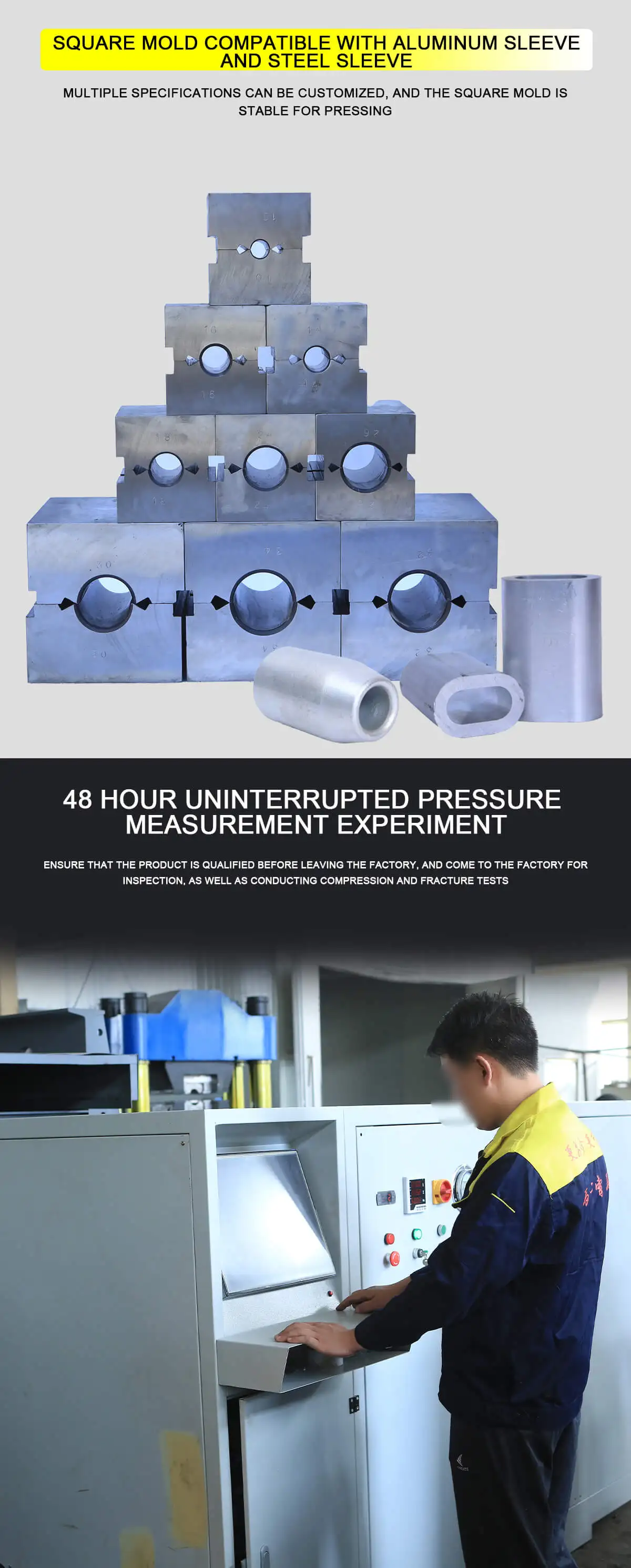

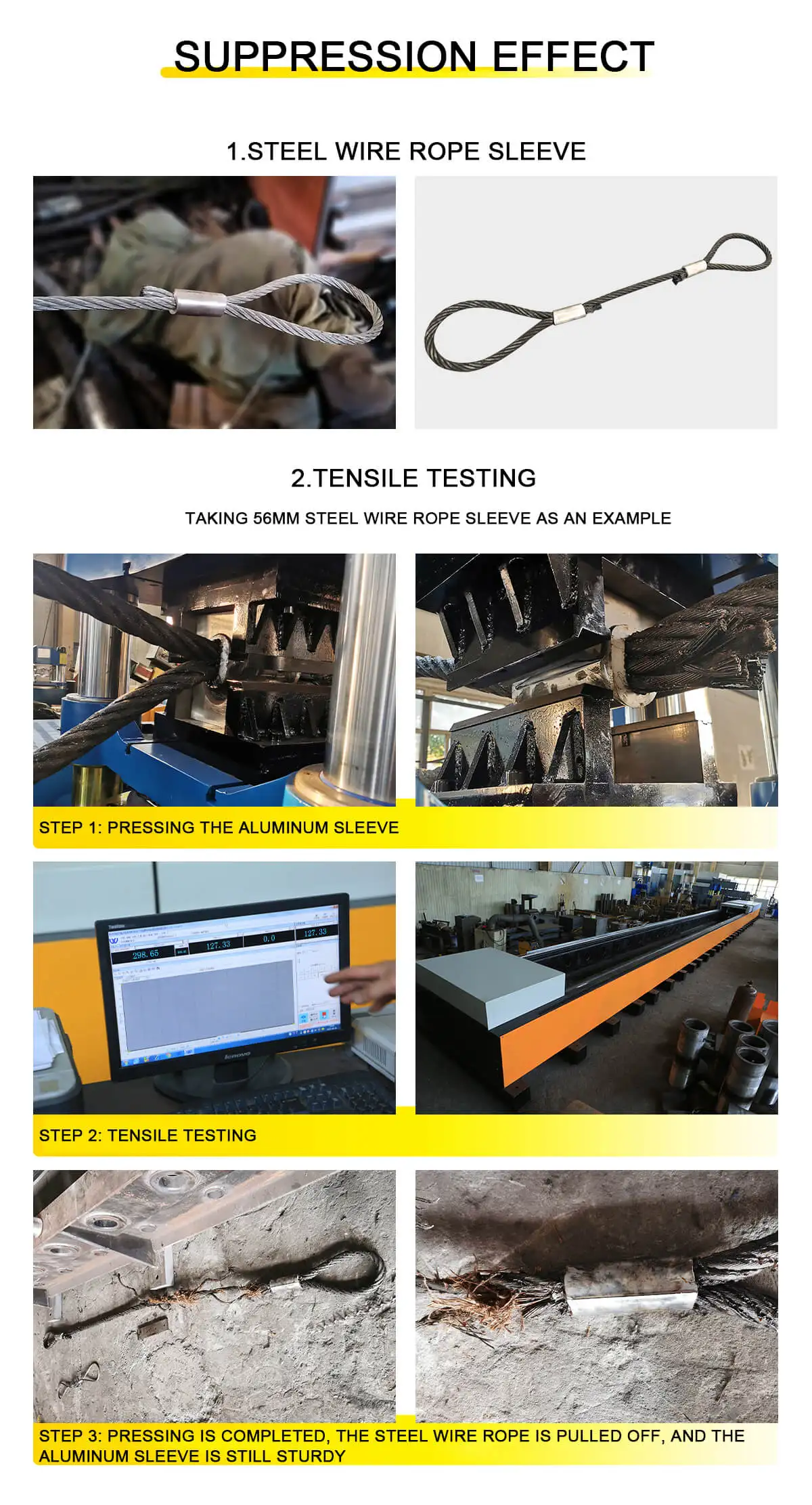

Key specs: machine weight 2 tons; motor power 7.5 kW; return force 1500 kN; adjustable slide stroke 140 mm; overall dimensions 2 m x 1 m x 1.5 m. It incorporates motors, pumps and pressure vessels as core components.

3. What wire materials and sizes can the CLH300 handle?

The CLH300 is specifically designed for PVC-insulated wire and similar materials. The adjustable slide stroke (140 mm) provides flexibility for different wire sizes, but for exact diameter/range compatibility please provide your wire specifications to CHENLI or your distributor.

4. What are the electrical and power requirements for this machine?

The machine is driven by a 7.5 kW motor and requires an appropriate industrial power supply. Exact electrical specifications (voltage, phase, and current) can vary by market and configuration — please contact CHENLI or your local distributor for the precise electrical requirements for your unit.

5. What site and installation requirements should I plan for?

Plan for a sturdy, level floor capable of supporting the machine's 2-ton weight and allow clearance for the overall dimensions (2 m x 1 m x 1.5 m) plus operator access. You will likely need lifting equipment for placement and qualified electrical and mechanical personnel for installation and commissioning. CHENLI can provide detailed installation guidelines.

6. What safety features does the CLH300 include?

The CLH300 is designed for user-friendly operation and includes standard industrial safety provisions. For specifics such as emergency stop, guards, interlocks and any optional safety packages, request the machine's safety datasheet and user manual from CHENLI or your supplier.

7. How much maintenance does the CLH300 require and what is recommended?

Routine maintenance includes regular inspection of motors, pumps and hydraulic/pressure systems, lubrication of moving parts, and checks for wear on tooling and guides. CHENLI provides a recommended maintenance schedule and can supply replacement parts and service guidance.

8. What warranty and after-sales support come with the CLH300?

The CLH300 comes with a 6-month warranty. This typically covers manufacturing defects; for full warranty terms, coverage details and available after-sales service (spare parts, remote support, on-site service), consult CHENLI or your authorized dealer.

9. Are spare parts and consumables readily available?

Yes — the machine uses standard components such as motors, pumps and pressure vessels, and CHENLI supplies genuine spare parts. Contact CHENLI or an authorized distributor for part numbers, availability and lead times.

10. How is the CLH300 packaged for shipping?

Units are packaged in a plywood wooden case to protect the machine during transport.

11. Does CHENLI offer training for operators of the CLH300?

Yes. The CLH300 is designed to be user-friendly for operators of varying skill levels, and CHENLI or its distributors can provide training on operation, maintenance and safety upon request.

12. Can the CLH300 be customized or upgraded?

CHENLI offers customization options and upgrades depending on production needs (controls, tooling, automation, etc.). Discuss your specific requirements with CHENLI sales to explore available modifications and options.

13. What is the typical lead time and how do I order a CLH300?

Lead time depends on stock, configuration and shipping destination. Contact CHENLI or an authorized distributor for current availability, quotation and ordering details.

14. Does the CLH300 have any certifications or compliance documentation?

Certification and compliance (for example CE, ISO or other local approvals) depend on the configuration and destination market. Request the machine's certification documentation from CHENLI to confirm compliance for your region.

15. Who should I contact for technical questions, spare parts or service?

For technical support, spare parts, service, warranty claims or sales inquiries, contact CHENLI directly or your authorized CHENLI distributor. They can provide manuals, parts lists, service packages and contact information for local support.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading