B21, China Town Mall, Midrand

Water Mist Blower Sprayer Machine For Agricultural Construction Plant

- Section : Machinery

- Category : Sprayers

- SKU : 1601026970247

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 06 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the Water Mist Blower Sprayer Machine and what is it used for?

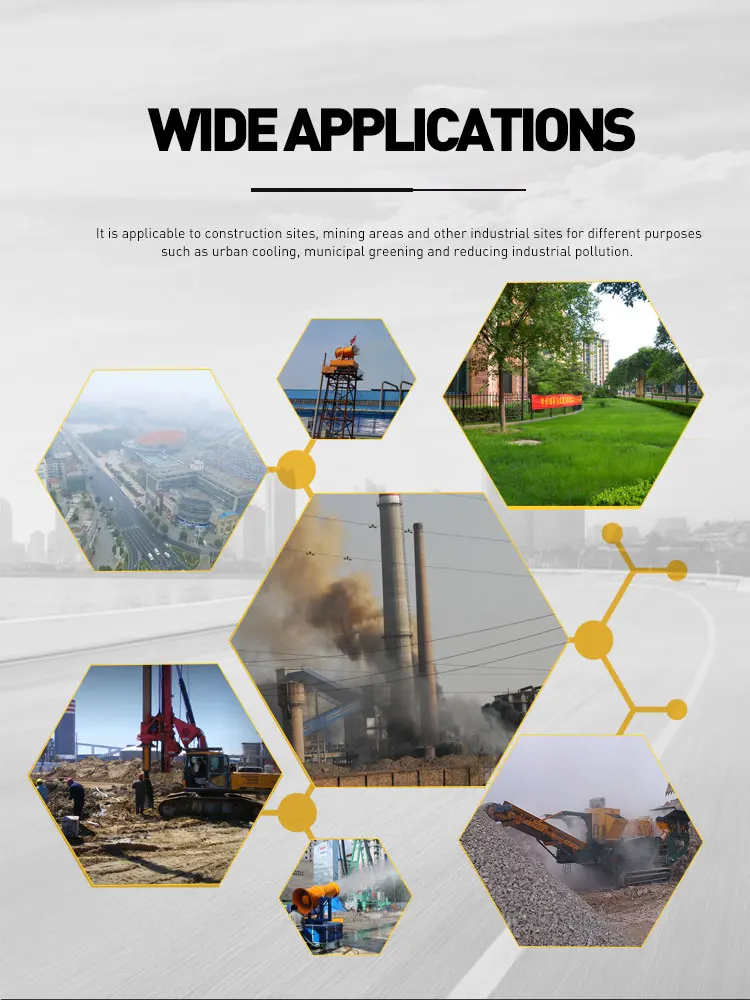

It is a high-pressure water mist blower (fog cannon) designed for fire protection, explosion safety and environmental protection. Typical uses: dust suppression on construction and demolition sites, dust control in mining/coal yards/ports/power plants/steel mills, large-area disinfection, and fire/explosion mitigation.

2. What are the main specifications of model ZT-80?

ZT-80 key specs: pitch angle -5° to 35°, quiet wind range 80–85 m, rotation angle 0–340°, water mist particle diameter 30–150 μm, weight 1350 kg, power ≤45 kW, size 1950 × 2300 × 1926 mm.

3. How does the water mist extinguish fires or control dust?

The machine creates very fine water droplets that rapidly evaporate, absorbing heat and reducing temperature, while also displacing oxygen locally and wetting particulate matter to settle dust and suppress re-entrainment.

4. Is the unit explosion-proof and safe for hazardous areas?

The product is designed with explosion-proof characteristics for hazardous environments. For specific hazardous-area classifications and certifications (e.g., ATEX/IECEx), confirm with the manufacturer or supplier and follow local safety regulations.

5. How is the machine controlled?

It uses a PLC control system that can store control instructions, automatically manage start/stop and rotation, and execute preset programs for automated operation.

6. What mounting and mobility options are available?

The unit is movable, can be mounted on vehicles or trailers, or fixed in place. Configurations vary by project; discuss mounting options with the supplier to match site requirements.

7. What water supply does the unit require?

A high-pressure water supply is required. Some configurations include onboard pumps; others need an external high-pressure source. Confirm the required flow rate and whether a pump is included with the supplier for your model.

8. What maintenance is required?

Regular maintenance includes cleaning and inspecting nozzles and filters, checking hydraulic cylinders and hoses, inspecting aluminum fan blades for damage, testing the PLC/electrical system, verifying heat-trace operation in winter, and lubricating moving parts per the maintenance schedule.

9. Can it operate in cold climates or winter conditions?

Yes — the machine features a heat tracing insulation system to prevent pipeline icing and improve operational stability in low temperatures. Ensure heat tracing power is connected and maintained to guarantee reliable winter operation.

10. What particle size and coverage can I expect?

Atomized particle diameters are typically 30–150 μm, providing uniform atomization and wide coverage. The quiet wind effective range is approximately 80–85 m for ZT-80, though effective coverage depends on site conditions and wind.

11. What power and installation requirements should I plan for?

ZT-80 requires up to 45 kW electrical power. Installation needs include a suitable power supply, secure mounting/foundation (if fixed), hydraulic/electrical connections, and proper grounding. Professional installation by qualified technicians is recommended.

12. Are there any safety precautions operators must follow?

Yes. Operators should be trained on system controls and emergency stops, use appropriate PPE, maintain safe standoff distances during operation, follow electrical and explosion-proof guidelines, and perform pre-operation inspections.

13. What are the advantages of the machine's construction (materials/features)?

Features include aluminum alloy fan blades for high hardness and light weight (improved airflow and energy efficiency), a dual hydraulic cylinder support for stable long-stroke operation and vibration reduction, and a PLC system for reliable automated control.

14. How do I get spare parts, service, or certification documents?

Contact the manufacturer or authorized dealer to request spare parts, maintenance service, and certification/test documents. Keep your model/serial number and purchase information available to speed up support.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading