B21, China Town Mall, Midrand

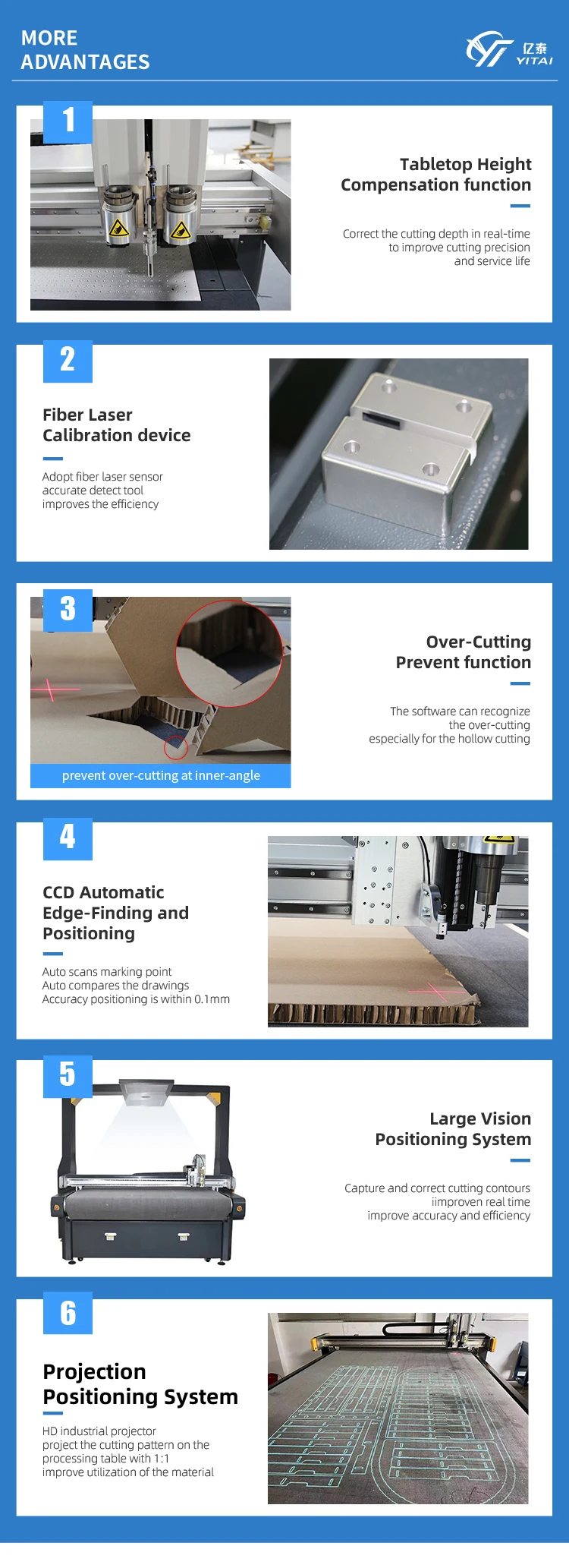

uv flatbed printer pvc box sample die cutting machine

- Section : Machinery

- Category : Paper Production Machinery

- SKU : 1600682442433

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 07 May, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is a UV flatbed printer used for?

A UV flatbed printer is used for printing directly onto various materials, including PVC, wood, glass, and metal, making it ideal for creating custom designs and graphics on items such as boxes, signage, and promotional products.

2. What is a PVC box sample die cutting machine?

A PVC box sample die cutting machine is designed to cut PVC sheets into specific shapes and sizes, allowing users to create prototypes and samples of packaging boxes with precision and efficiency.

3. How does the die cutting process work?

The die cutting process involves using a die that is shaped to the desired cut, which is then pressed onto the material to cut it out. This can be done either manually or with automated machinery for greater efficiency.

4. What are the advantages of using a UV flatbed printer?

Some advantages of using a UV flatbed printer include high-quality image resolution, the ability to print on a wide variety of substrates, quick drying times, and durability of prints due to UV curing.

5. Can this machine print on materials other than PVC?

Yes, this machine can print on various materials including wood, acrylic, glass, metal, and more, making it versatile for different applications.

6. What types of cutting heads are available for the machine?

The machine typically supports multiple cutting heads, each designed for different applications, such as contour cutting, kiss cutting, and heavy-duty cutting for thicker materials.

7. Is the UV flatbed printer suitable for small businesses?

Absolutely! The UV flatbed printer is suitable for small businesses looking to produce high-quality prints and prototypes efficiently, allowing for customization and unique designs.

8. How does the UV curing process work?

The UV curing process uses ultraviolet light to instantly cure or dry the ink as it is printed, allowing for immediate handling and use of the printed materials.

9. What is the maximum size of materials that can be printed?

The maximum size of materials that can be printed depends on the specific model, but many UV flatbed printers can accommodate large sheets, typically up to 4x8 feet or larger.

10. What maintenance is required for the machine?

Regular maintenance includes cleaning the print heads, checking the UV lamps, and ensuring the cutting blades are sharp and in good condition. It is also important to keep the machine free of dust and debris.

11. What is the typical printing speed of a UV flatbed printer?

The printing speed can vary based on the model and settings, but many UV flatbed printers can produce prints at speeds ranging from 10 to 100 square meters per hour.

12. Can I create custom designs with the software provided?

Yes, most UV flatbed printers come with user-friendly software that allows you to create and customize designs easily, or you can use external design software and import your files.

13. Is training provided for using the machine?

Yes, training is usually provided with the purchase of the machine, including operational guidelines and best practices for printing and cutting.

14. What kind of warranty is offered with the machine?

Warranties can vary by manufacturer, but many UV flatbed printers come with a standard warranty that covers parts and labor for a specified period, typically one to two years.

15. How can I get technical support for the machine?

Technical support can be accessed through the manufacturer's customer service, which may include phone support, online resources, and in some cases, on-site assistance.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals

Latest Arrivals

26 January 2026

Toilet paper making machine

Toilet paper making machine

Toilet paper Rewinding Machine

latest arrivals

offloading

order success

order collection

order offloading