B21, China Town Mall, Midrand

Trustworthy alluvial Gold mining equipment

- Section : Machinery

- Category : Mining Machinery

- SKU : 60023341793

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 23 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is the primary function of the Trustworthy alluvial gold mining equipment?

The primary function of the Trustworthy alluvial gold mining equipment, specifically the shaking table, is to separate and concentrate valuable minerals such as gold, tungsten, tin, and other rare metals based on their density.

2. What materials can the shaking table effectively separate?

The shaking table can effectively separate materials such as tungsten, tin, lead, zinc, gold, silver, tantalum, niobium, monazite, zircon, and ilmenite.

3. What are the key features of the shaking table?

Key features of the shaking table include a high concentration ratio, efficient separation, easy operation and adjustment, strong wear resistance, anti-chemical corrosion, and the ability to withstand harsh environments.

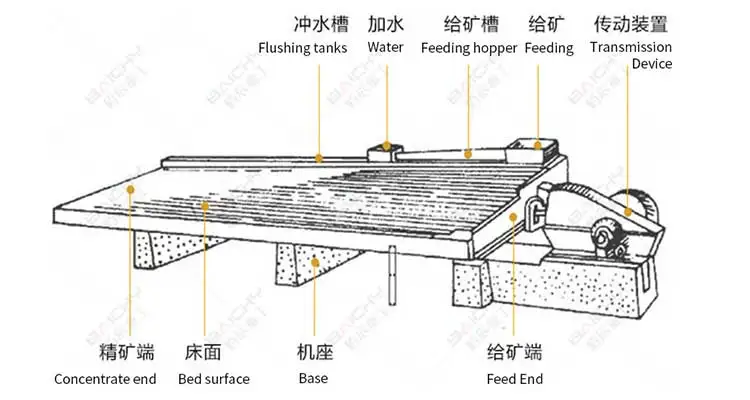

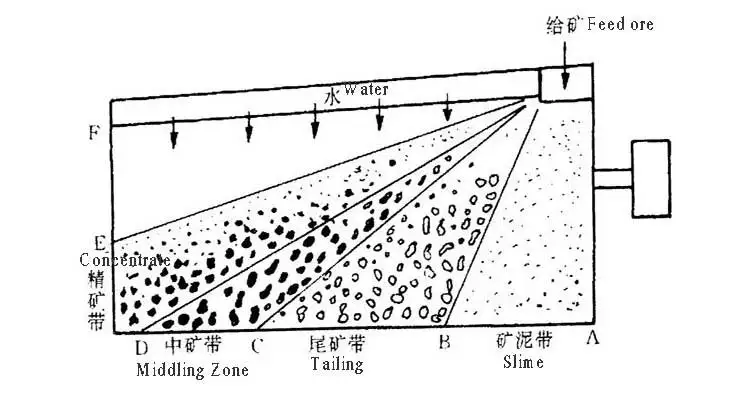

4. How does the shaking table work?

The shaking table operates by moving back and forth longitudinally, causing particles to move diagonally across the deck based on size and density. Lighter materials exit on the tailings side while heavier materials are concentrated.

5. What is the size of the shaking table?

The shaking table size ranges from 1500 mm to 1850 mm in width and 4500 mm in length.

6. What is the slope range of the shaking table?

The slope range of the shaking table is between 0 to 5 degrees.

7. What is the feeding size capacity for the shaking table?

The shaking table can handle coarse sand with a size of 2-0.5 mm, fine sand of 0.5-0.074 mm, and slurry of 0.074 mm.

8. How is the shaking table adjusted for different operations?

The shaking table can be easily adjusted for different operations by modifying the stroke length and the angle of the table to optimize the separation process.

9. What is the stroke frequency of the shaking table?

The shaking table has a stroke frequency ranging from 240 to 360 times per minute.

10. Can the shaking table recover small gold particles?

Yes, the shaking table is particularly effective at recovering small gold particles even with a relatively high feed rate.

11. Is the shaking table resistant to harsh environments?

Yes, the shaking table is designed to be resistant to harsh environments, including strong wear and chemical corrosion.

12. What types of ores can the shaking table be used in?

The shaking table can be used in processing a variety of ores including placer ore dressing and fissure filling processes.

13. Is the shaking table easy to manage?

Yes, the shaking table features easy management and adjustment, making it user-friendly for operators.

14. What materials are used in the construction of the shaking table?

The shaking table is typically constructed from fiberglass reinforced plastic with an embedded skeleton composite structure for durability.

15. What are the applications of the shaking table?

Applications of the shaking table include mineral separation in gold mining, as well as the recovery of other metals such as tungsten, tin, and rare earth elements from various ores.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals