B21, China Town Mall, Midrand

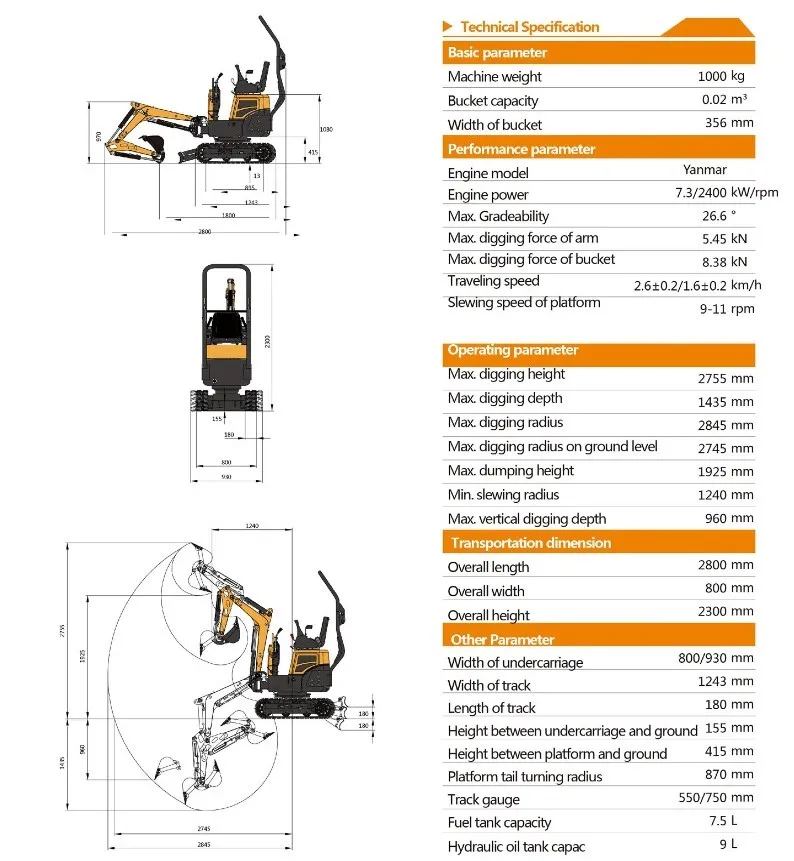

Tough hydraulic tamping unit excavator machinery for track works equipments for railway market

- Section : Machinery

- Category : Engineering & Construction Machinery

- SKU : 1600835140322

- Shipping Timeframes: All orders are processed within 2-5 business days (excluding weekends and holidays). After your order has been processed, the estimated delivery time is before 20 Mar, 2026, depending on customs, Please note that due to high demand, some items may experience longer shipping times, which will be communicated at order confirmation email.

- Order Processing Time: Please allow 2-5 business days for us to process your order before it is shipped . Orders placed after 16:00 on Fridays, or during weekends and public holidays, will begin processing on the next business day. Processing times may be extended during peak seasons or sales events.

- Manufacturing Time: Some products needs manufacturing time, the manufacturing process will take approximately 10-30 business days depending on the product. This timeframe may vary depending on the complexity of the product and current demand. but this will be communicated with you during order confirmation.

- Returns and Exchanges: We offer a 30-day return policy for most items. If you are not completely satisfied with your purchase, you may return it within 30 days of receipt for a refund or exchange. Items must be unused, in their original packaging, and accompanied by proof of purchase. Return shipping costs are the responsibility of the customer, unless the item was damaged or defective upon arrival.

1. What is a hydraulic tamping unit?

A hydraulic tamping unit is a specialized piece of machinery used to compact and stabilize track ballast in railway construction and maintenance, ensuring the tracks are properly aligned and secure.

2. What types of railway works can this tamping unit be used for?

This tamping unit is designed for various railway track works, including new track installation, maintenance of existing tracks, and reconstruction projects.

3. How does the tamping process work?

The tamping process involves the hydraulic tamping unit applying vibration and pressure to the track ballast, effectively compacting it to improve stability and support for the railway sleepers.

4. Is this equipment suitable for all types of railway systems?

Yes, the tough hydraulic tamping unit is versatile and can be used for different railway systems, including freight, passenger, and light rail networks.

5. What are the key features of this tamping unit?

Key features include robust hydraulic systems, high compaction efficiency, ease of operation, and compatibility with various track gauges.

6. What is the weight of the hydraulic tamping unit?

The weight can vary depending on the specific model, but it is designed to be heavy-duty to withstand rigorous tamping operations.

7. How is the tamping unit powered?

The hydraulic tamping unit is typically powered by a diesel engine or can be adapted to electric power sources, depending on the model and application.

8. Can the tamping unit operate in difficult terrain?

Yes, the design of the tamping unit allows it to operate effectively in various terrains, including uneven ground and challenging environmental conditions.

9. What safety features are included with the hydraulic tamping unit?

Safety features often include emergency stop buttons, operator protection guards, and stability control systems to prevent accidents during operation.

10. How often does the tamping unit require maintenance?

Routine maintenance is recommended after every 100 hours of operation, including checks on hydraulic fluid levels, filters, and general wear and tear.

11. Is training required to operate the tamping unit?

Yes, operators should undergo specific training to ensure safe and effective use of the hydraulic tamping unit, including understanding its controls and safety protocols.

12. What is the expected lifespan of the hydraulic tamping unit?

With proper maintenance, the hydraulic tamping unit can have a lifespan of 10-15 years or more, depending on usage and operating conditions.

13. Are there any additional attachments available for this tamping unit?

Yes, various attachments can enhance functionality, such as different tamping tools or supplementary equipment for handling ballast.

14. What are the environmental considerations for using this equipment?

The tamping unit is designed to minimize environmental impact, with options for low-emission engines and features to reduce noise pollution during operation.

15. Where can I purchase or rent this hydraulic tamping unit?

You can purchase or rent the hydraulic tamping unit through authorized dealers, equipment rental companies, or directly from manufacturers specializing in railway machinery.

Latest Order Arrivals

Discover our latest orders

12 Heads Embroidery Machine

Dewatering Pump Machine

Order Collection

Portable Water Drilling Rig

Order Usefully Collected

Batch of Orders

Agriculture Processing Machines

Meat Grinder Machine

Water Pump Equipment

Packaging Machine and accessories

Fabrics Manufacturing Equipment

Mining Equipments

Food Processing Machine

Batch of Orders

Batch of Orders

Latest Orders Labelled

wheel alignment machines

new arrivals

Pre Orders Offloading

Latest Arrivals

Latest Arrivals